客户期望更安静的产品,而相关竞争永无止境,因此声品质可以成为产品差异化因素。噪音法规日益收紧,会影响产品销售。Simcenter 声学仿真解决方案有助于减少声场预测时间,并可将发动机试车等复杂工作的时间缩短数周。

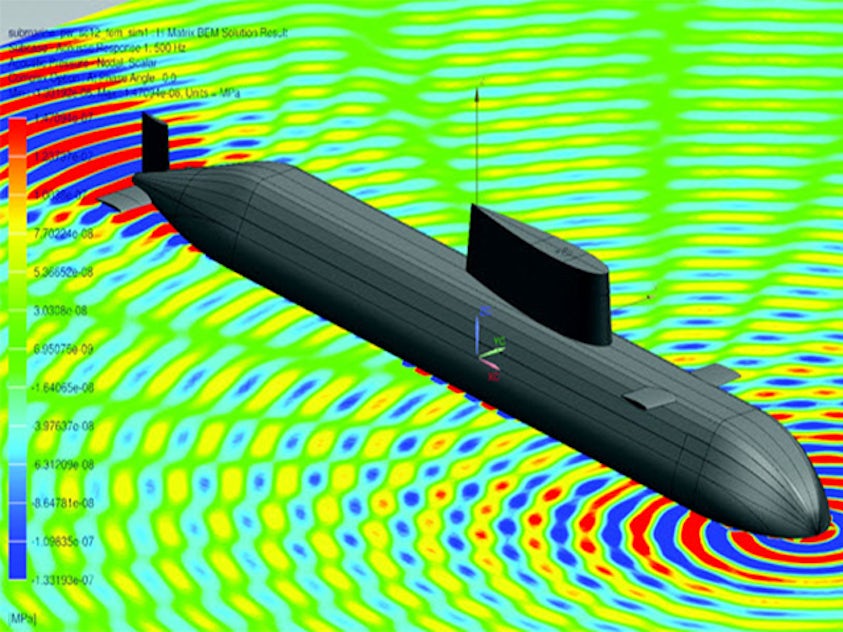

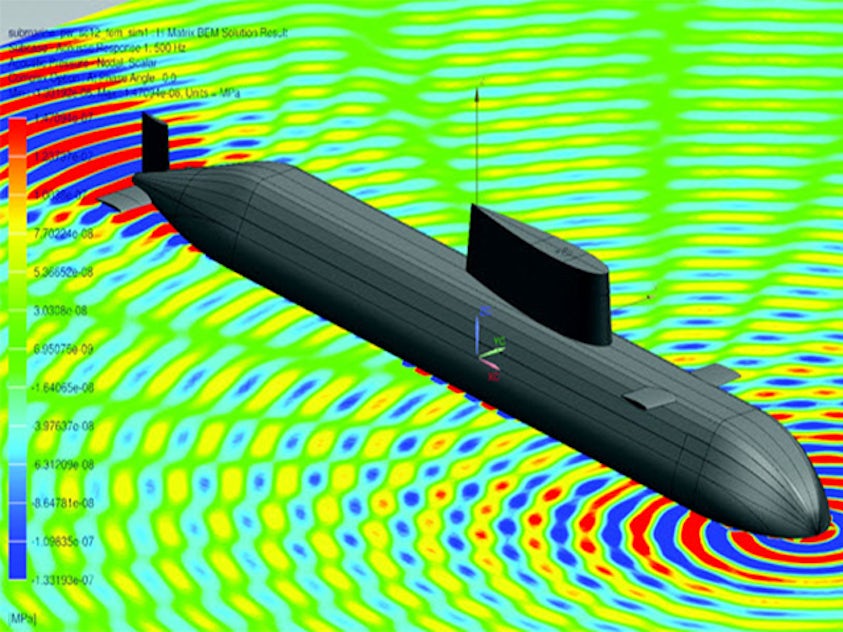

Simcenter 在集成式解决方案中提供内场和外场声学仿真,可帮助您在设计早期做出明智决策,从而优化产品的声学性能。可扩展的一体化建模环境与高效的求解器和易于解读的可视化功能恰当地结合在一起,让您能够快速获得对产品声学性能的洞察。

客户期望更安静的产品,而相关竞争永无止境,因此声品质可以成为产品差异化因素。噪音法规日益收紧,会影响产品销售。Simcenter 声学仿真解决方案有助于减少声场预测时间,并可将发动机试车等复杂工作的时间缩短数周。

Simcenter 在集成式解决方案中提供内场和外场声学仿真,可帮助您在设计早期做出明智决策,从而优化产品的声学性能。可扩展的一体化建模环境与高效的求解器和易于解读的可视化功能恰当地结合在一起,让您能够快速获得对产品声学性能的洞察。

Read how Mazda is perfecting in-vehicle audio with model-based development and full-vehicle simulation using Simcenter 3D and HEEDS to optimize audio acoustic performance and reduce simulation from 2.5 days to 4 hours.

公司:Mazda Motor Corporation, Mazda Engineering and Technology

行业:汽车及交通运输行业

位置:Fuchū, Hiroshima, Japan

Siemens 软件:HEEDS, Simcenter 3D Solutions