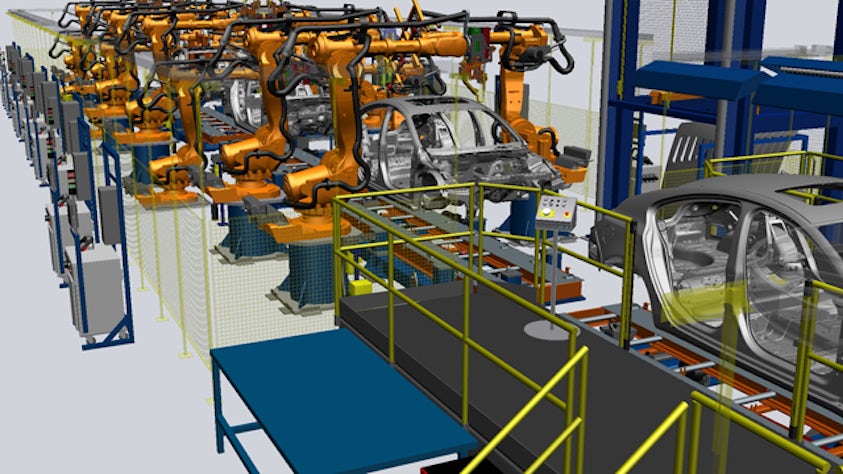

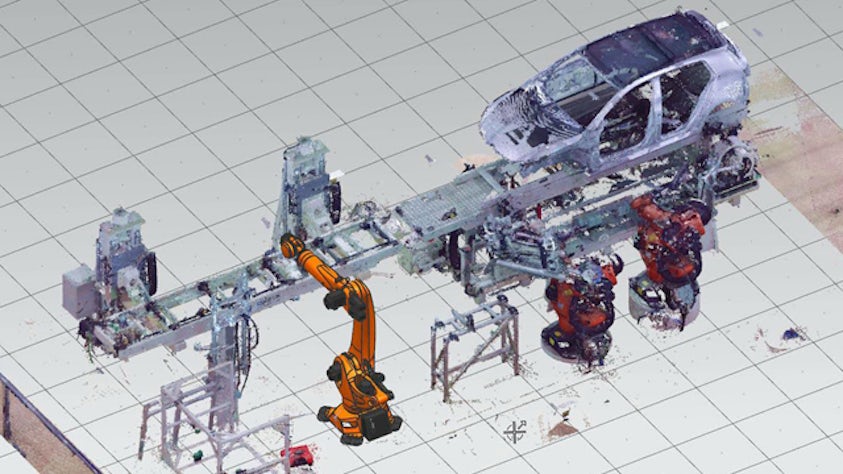

Conceptualize production layouts using 3D

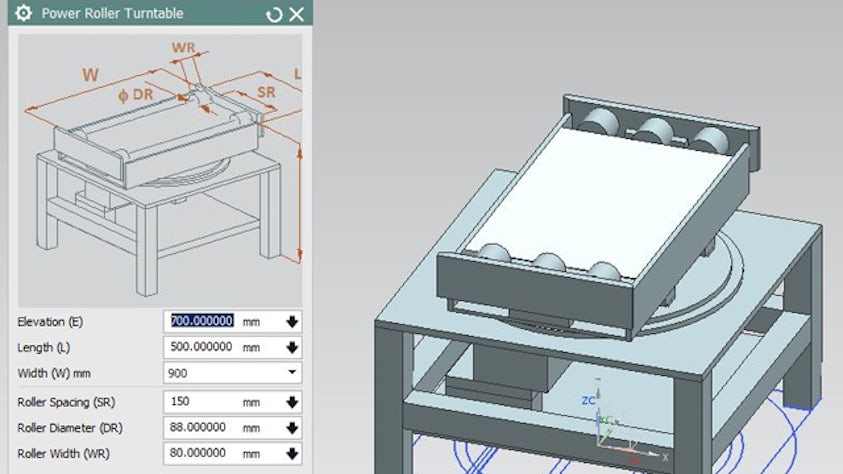

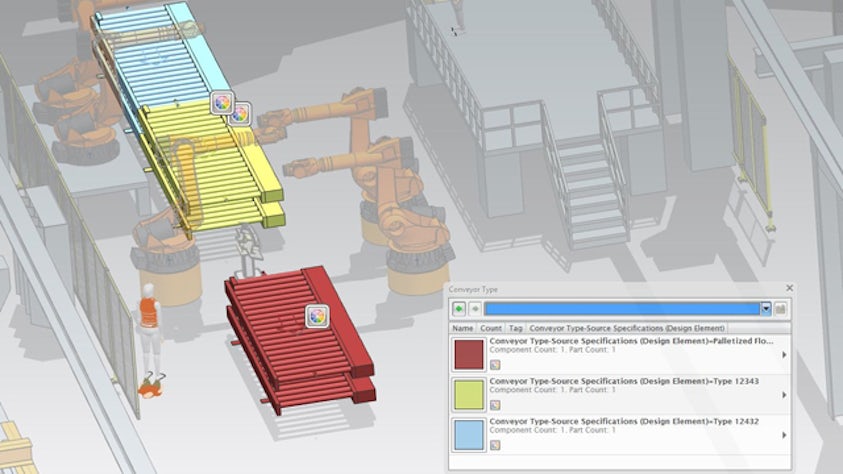

Leverage a complete production layout solution for manufacturing engineers. Enable efficient work with manufacturing components and easily accommodate changes. Use the integrated system to search, view and retrieve components across a fully classified library in Teamcenter, directly from NX.