Automatiza la programación NC para mejorar la productividad

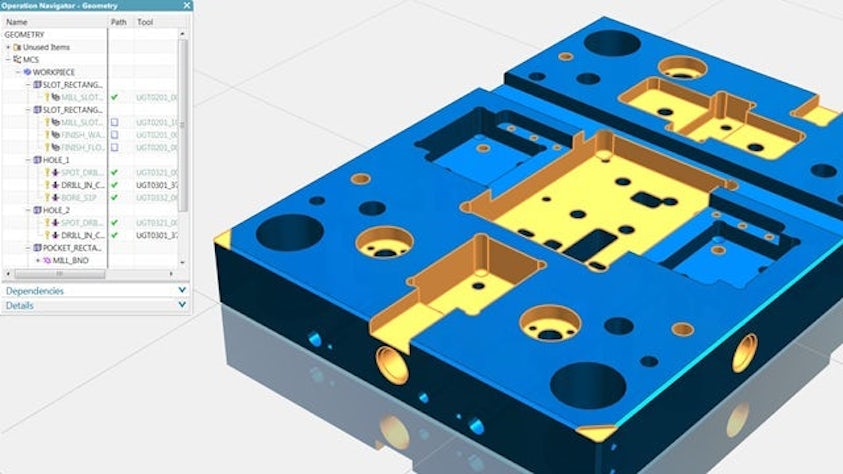

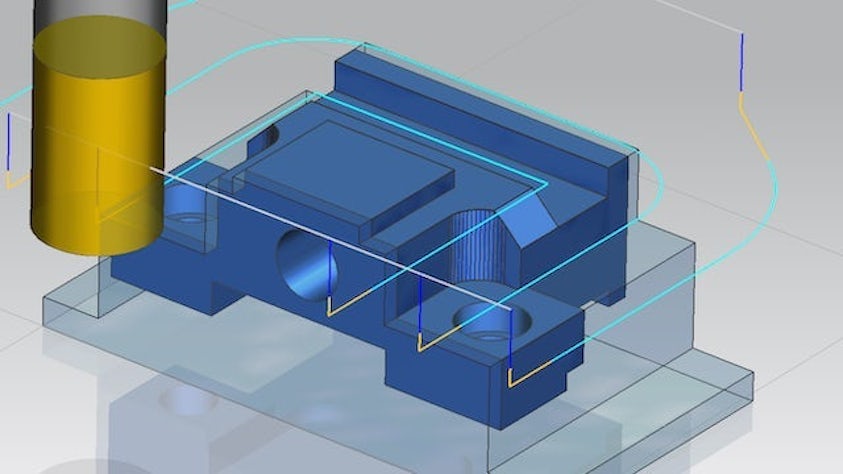

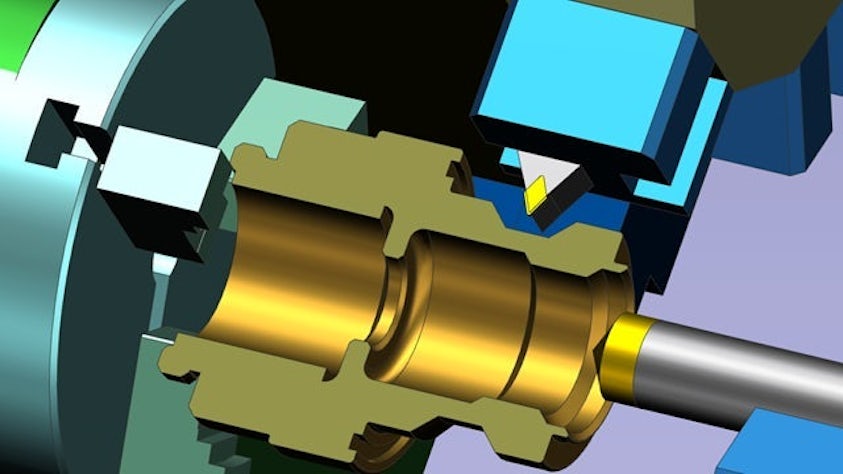

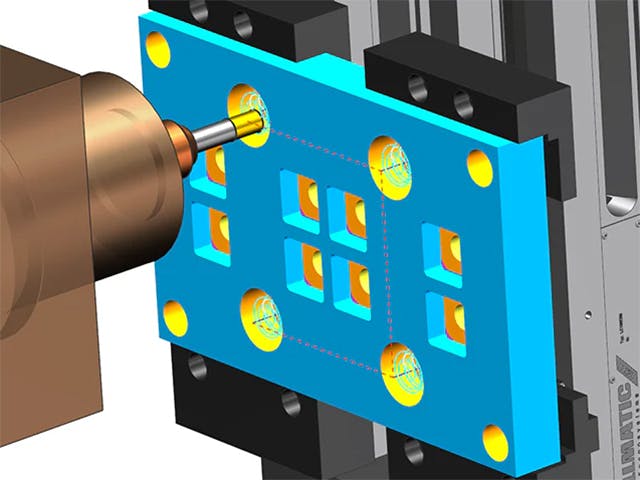

Utiliza el mecanizado basado en figuras para crear automáticamente operaciones de mecanizado de piezas prismáticas con muchas figuras, como cavidades, orificios y ranuras.

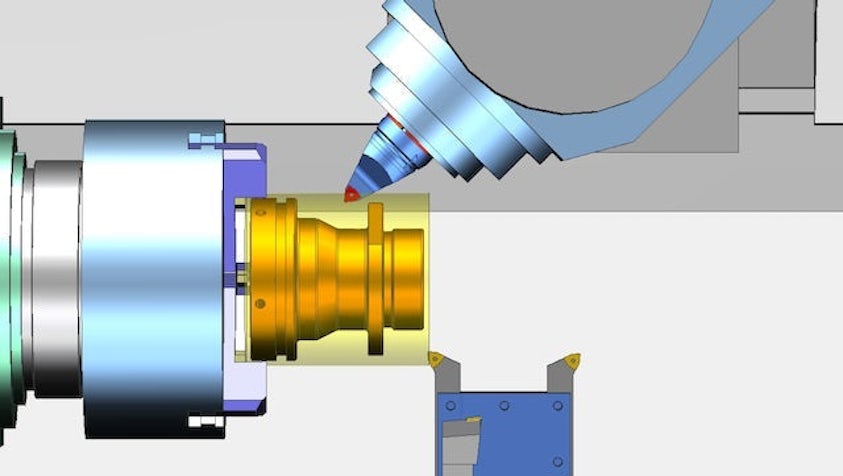

Captura la intención del diseño y automatiza aún más el proceso utilizando la información sobre productos y fabricación (PMI) integrada.

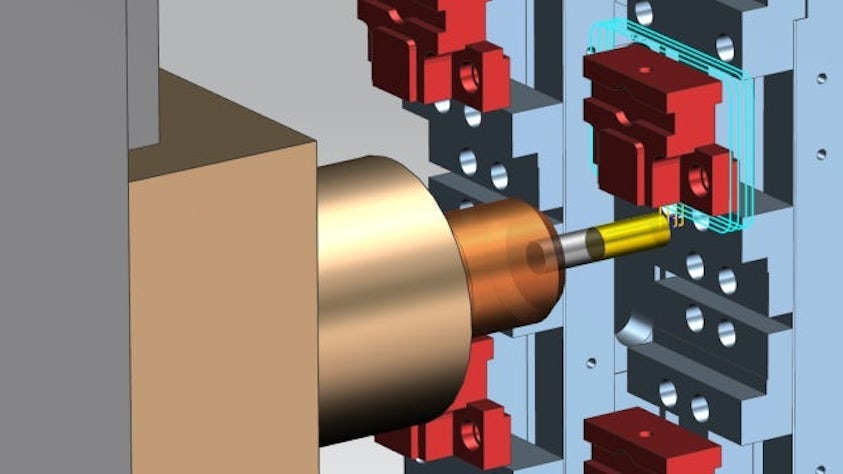

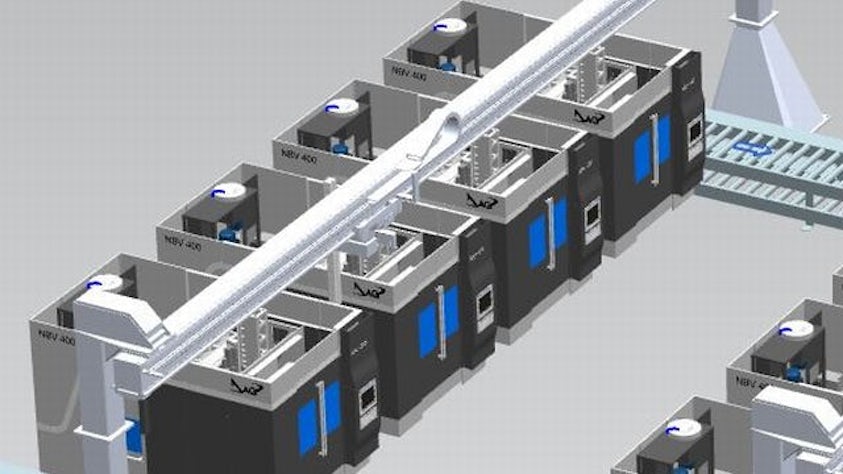

Las plantillas de procesos y la base de datos de mecanizado te permiten reutilizar las mejores prácticas y los datos de corte probados, lo que permite la estandarización del proceso.