Réduisez les obstacles à la préparation de la construction grâce à la simulation et au traitement parallèle dans le cloud avec NX Additive Manufacturing (AM) Build Optimizer. Les problèmes de qualité sont extrêmement coûteux lors de l'impression de pièces métalliques, mais les atténuer n'a plus besoin d'être un défi.

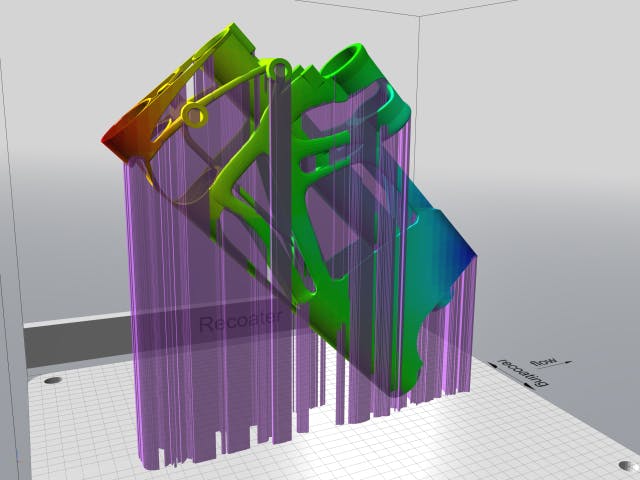

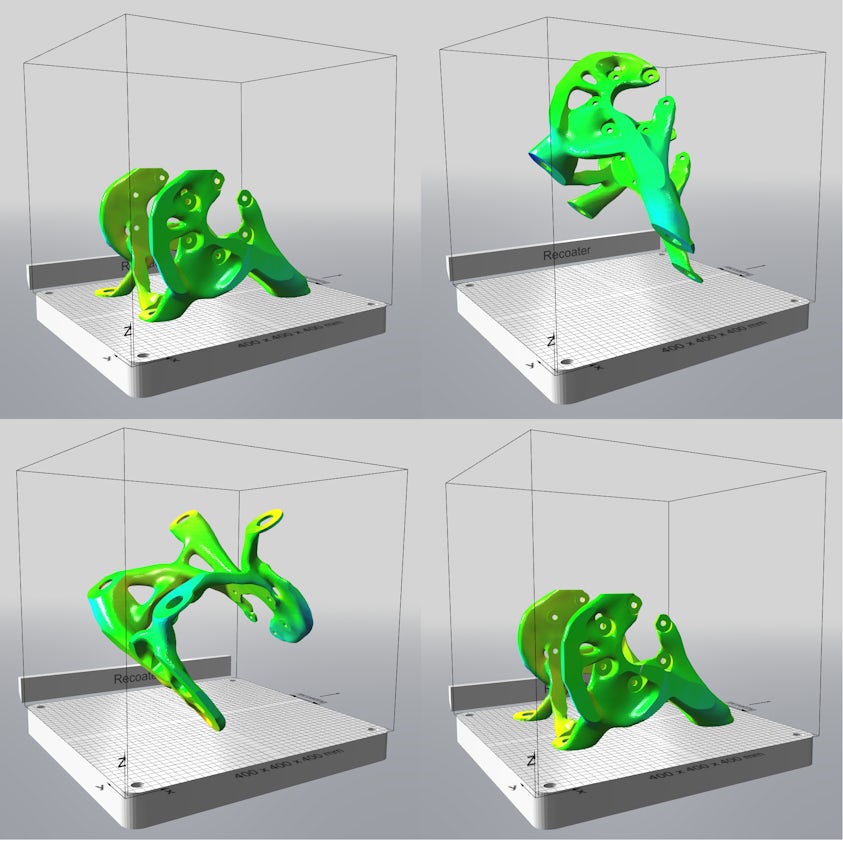

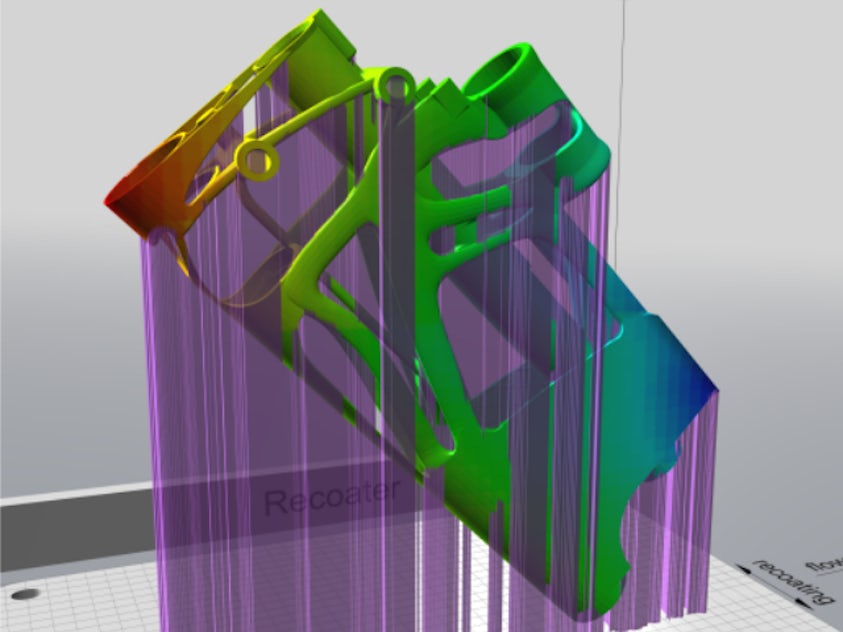

Optimisez l'orientation de l'impression

Générez automatiquement l'orientation optimale de l'impression des pièces pour une qualité maximale. Des orientations optimales peuvent être créées pour minimiser la distorsion, le volume du support, le retrait du support et le temps de construction.

Utilisez la puissance du traitement parallèle

Examinez plus de 100 orientations de pièces différentes en parallèle, puis obtenez l'orientation optimale ainsi qu'un rapport d'optimisation comprenant des estimations de coûts. Vous pouvez l'utiliser pour prendre les meilleures décisions possibles lors de la configuration de votre construction par fabrication additive.

Utilisez la solution dans le cloud ou de manière autonome

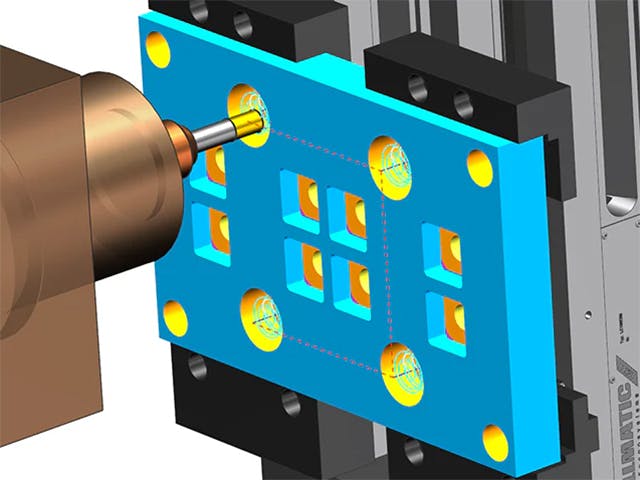

NX Build Optimizer est disponible en tant que solution cloud autonome conforme à l'ITAR, ou intégré à NX où les résultats de l'optimisation sont directement intégrés dans le processus de configuration de construction de la solution NX AM Fixed-Plane.

Obtenez une prédiction avancée des erreurs d'impression futures ainsi que des solutions pour :

- Traitement parallèle dans le cloud conforme à l'ITAR des exécutions de simulation d'orientation

- Génération de structures de support pour l'impression

- Analyse de plus de 100 simulations d'orientation en parallèle

- Cartographie visuelle de la distorsion totale, de la distorsion due aux contraintes résiduelles et de la distorsion due au processus d'impression

- Estimations de coûts tenant compte de la quantité totale de matériau fritté utilisé et du temps d'impression total requis