Dzięki zastosowaniu symulacji i przetwarzania równoległego w chmurze przy użyciu oprogramowania NX Additive Manufacturing (AM) Build Optimizer można usprawnić przygotowywanie procesu drukowania. Problemy z jakością podczas drukowania części metalowych są niezwykle kosztowne, ale ich wyeliminowanie nie musi już sprawiać trudności.

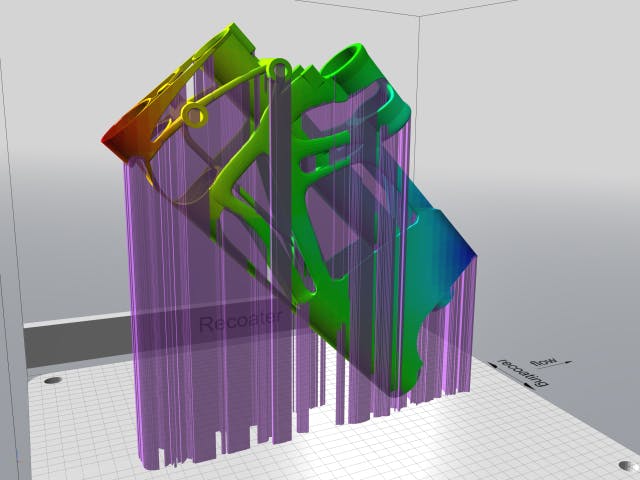

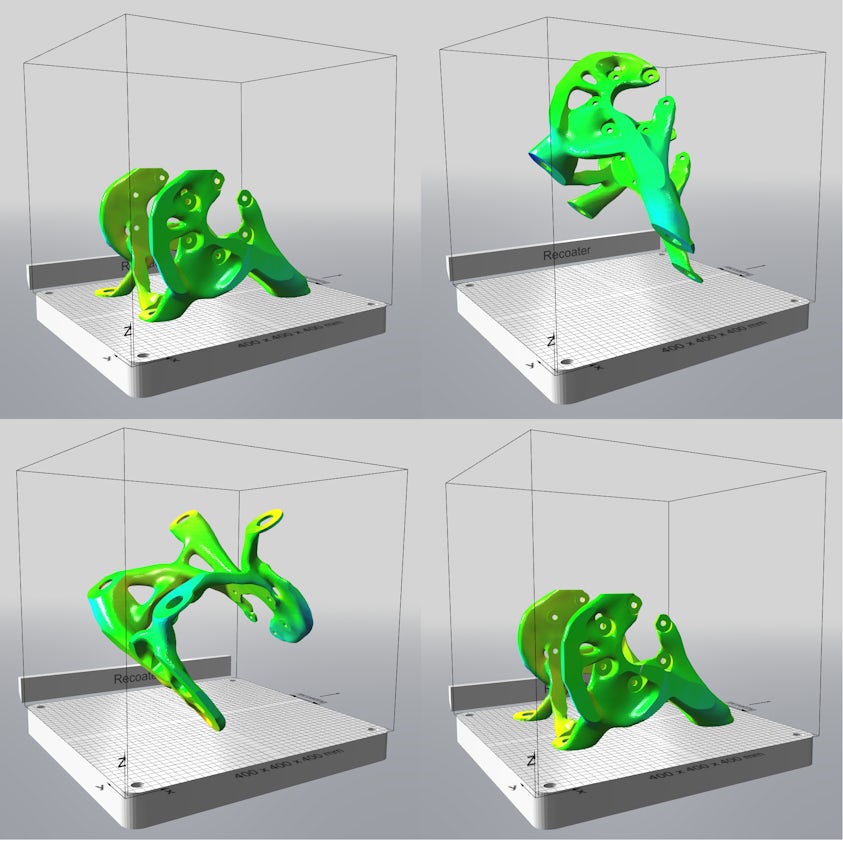

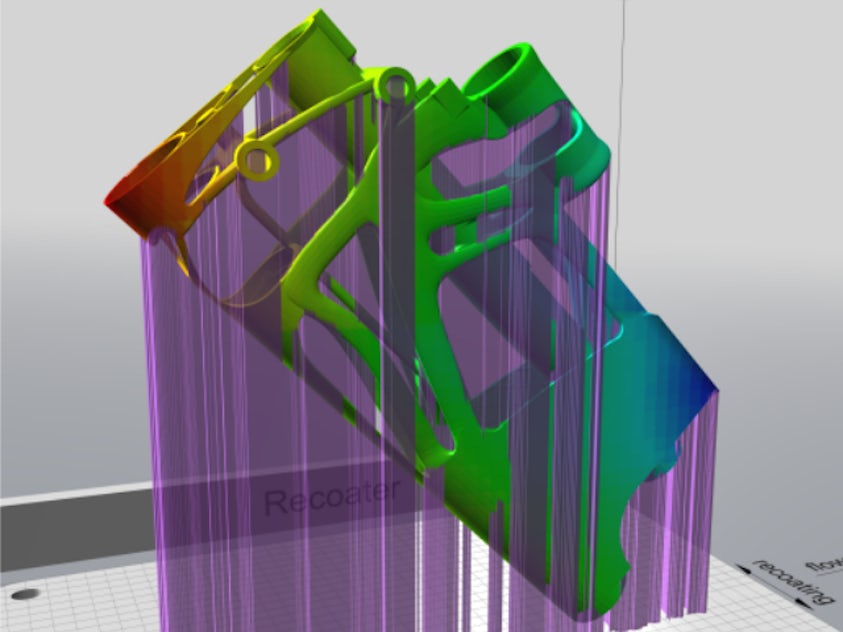

Optymalizacja orientacji wydruku

Dzięki automatycznemu generowaniu optymalnej orientacji drukowania części można osiągnąć najwyższą możliwą jakość. Uzyskanie optymalnej orientacji pozwala zminimalizować zniekształcenia i objętość podpór, usprawnić usuwanie podpór i skrócić czas drukowania.

Wykorzystanie możliwości zapewnianych przez przetwarzanie równoległe

Oprogramowanie umożliwia przeprowadzanie równoległej analizy ponad 100 różnych orientacji części w celu określenia optymalnych ustawień i utworzenia raportu zawierającego kosztorys. Na tej podstawie można podejmować najlepsze możliwe decyzje podczas konfigurowania procesu wytwarzania addytywnego.

Rozwiązanie chmurowe lub autonomiczne

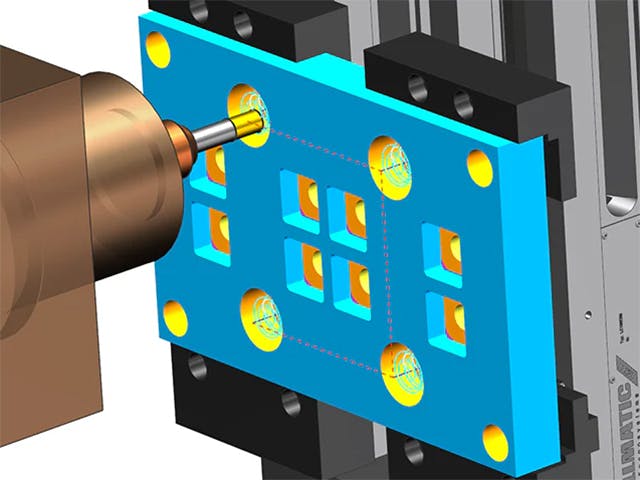

Oprogramowanie NX Build Optimizer jest dostępne jako samodzielne rozwiązanie chmurowe zgodne z przepisami ITAR lub w postaci zintegrowanej z oprogramowaniem NX, co umożliwia przekazywanie wyników optymalizacji bezpośrednio do procesu konfiguracji procesu drukowania w aplikacji NX AM Fixed-Plane.

Zaawansowane prognozowanie błędów drukowania oraz rozwiązania umożliwiające:

- równoległe przetwarzanie symulacji orientacji w chmurze zgodnie z przepisami ITAR;

- generowanie struktur podporowych wydruku;

- analiza ponad 100 równoległych symulacji orientacji

- wizualne odwzorowanie zniekształceń całkowitych, spowodowanych obciążeniami szczątkowymi oraz procesem drukowania;

- kosztorysy uwzględniające całkowitą ilość zużytego materiału spiekanego i łączny wymagany czas drukowania.