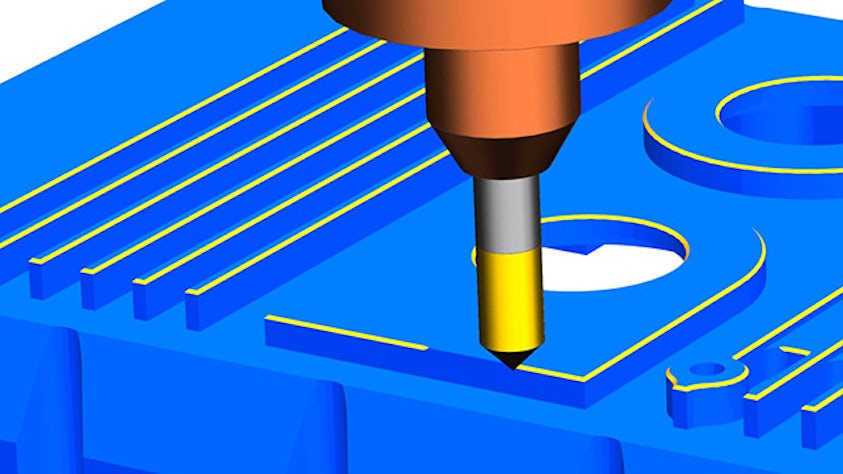

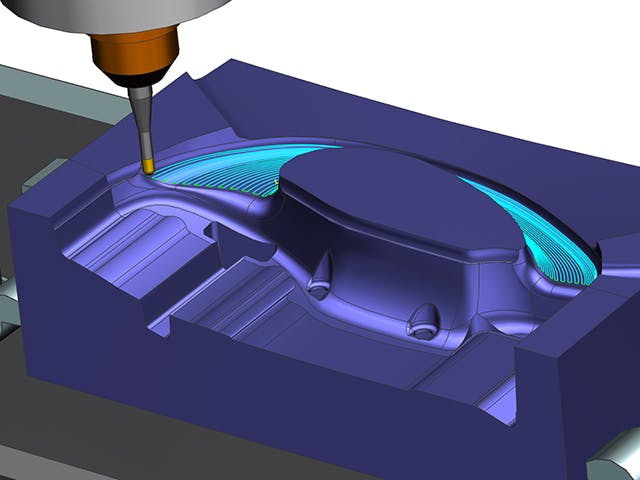

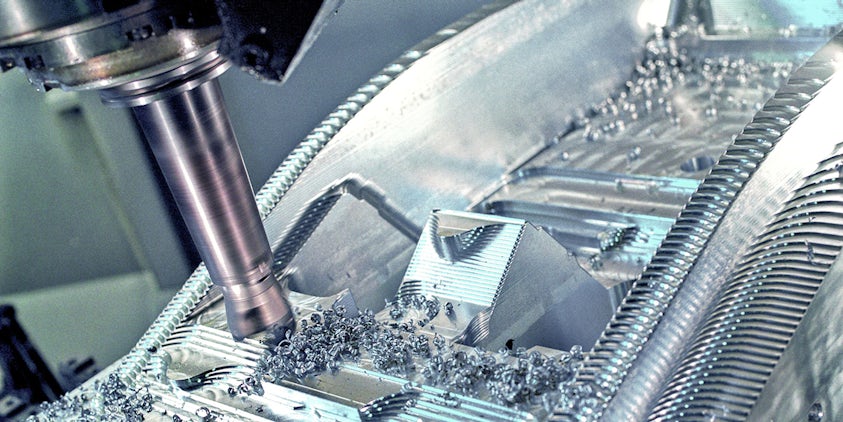

使用 3 轴铣削高级功能简化在任何 CAD 系统中创建的精密自由曲面零件的编程。

加速加工并提高质量

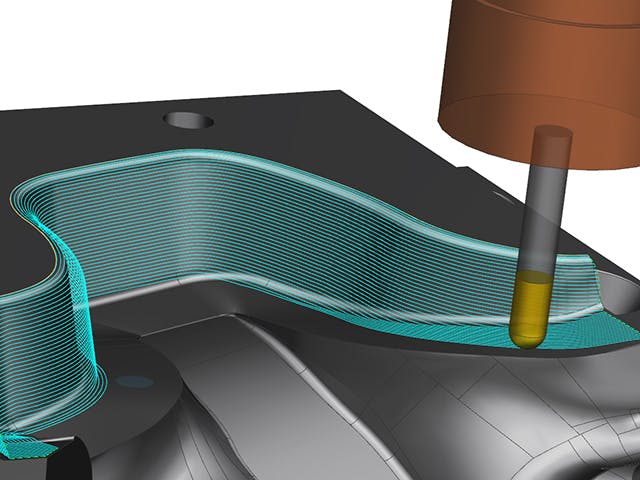

以较少的投入(例如遵循零件自然形状的高级精加工工序)创建平滑高效的刀轨,获得镜面般的表面粗糙度。

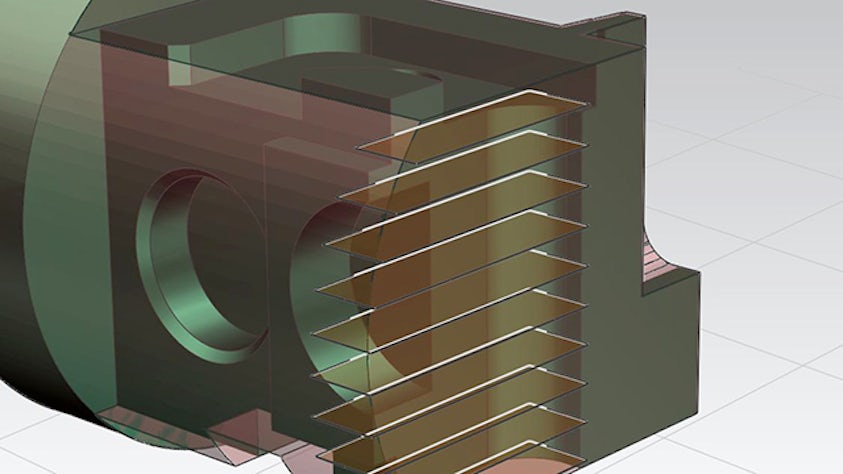

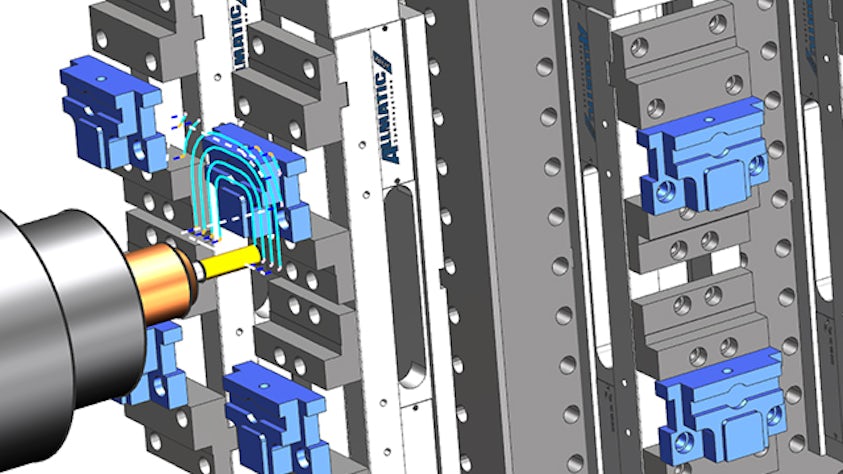

使用创新的 3D 自适应粗加工及其高速深切削,将加工周期缩短多达 60%,并提供更高质量的零件,例如模具和冲模。

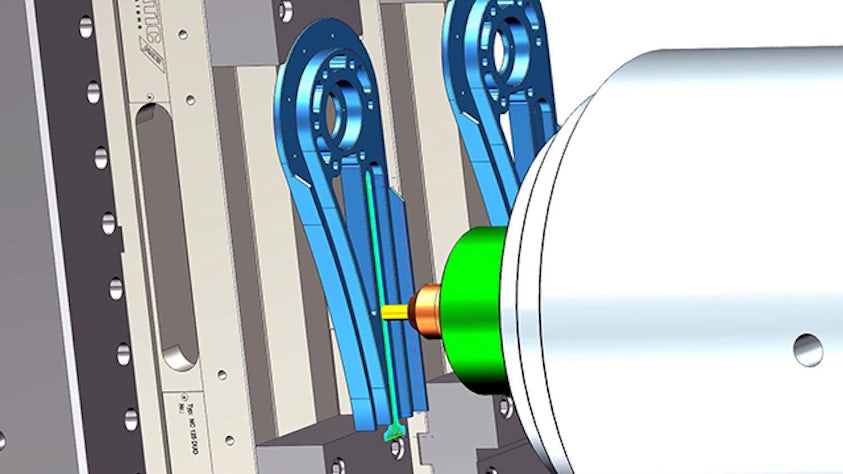

使用集成式 CAD 工具

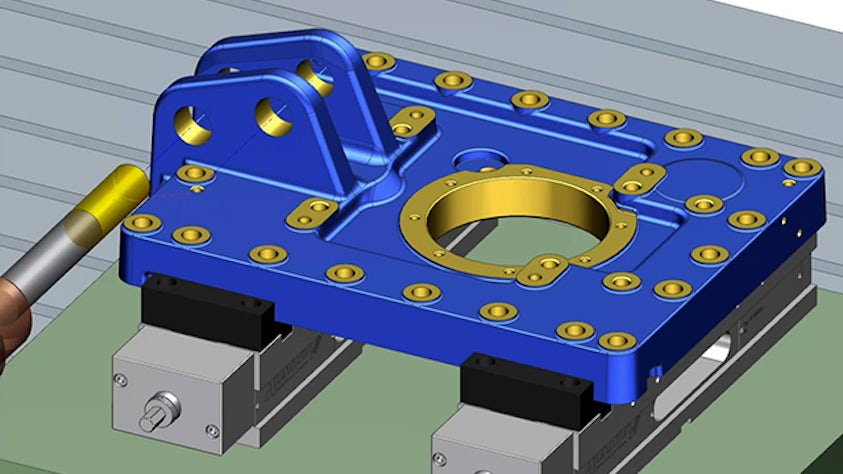

使用同步建模技术直接编辑 3D 零件模型,加快数控编程。此外,使用交互式编辑工具开发铸造和分级模型。

生成经验证的程序

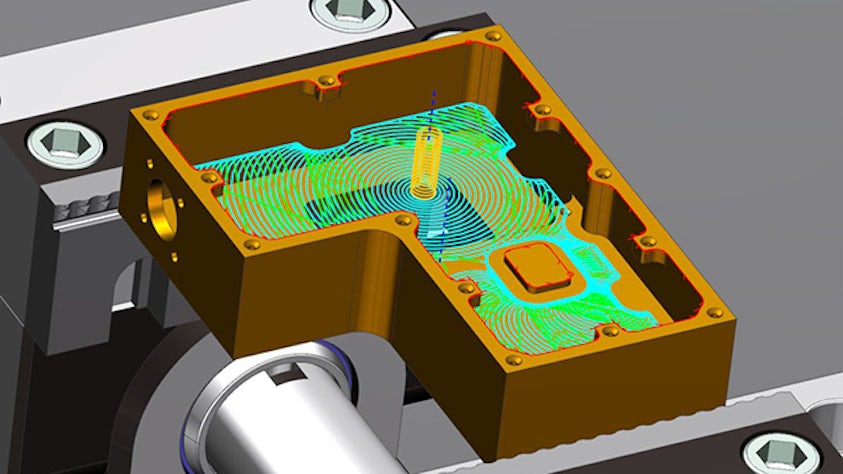

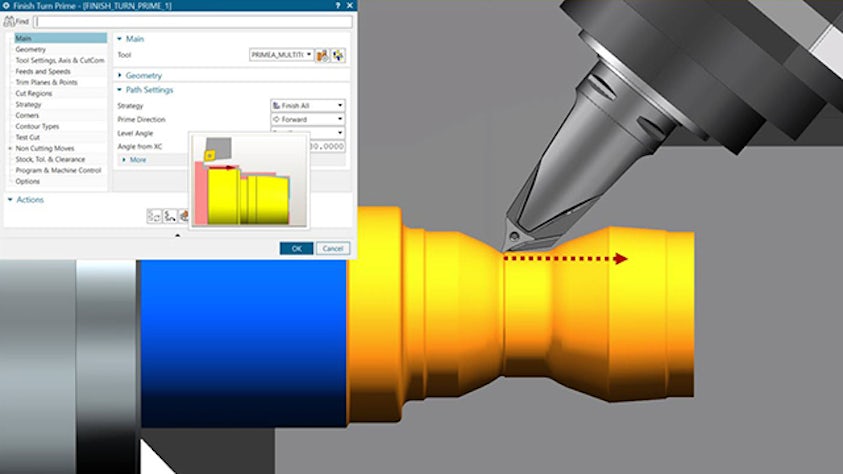

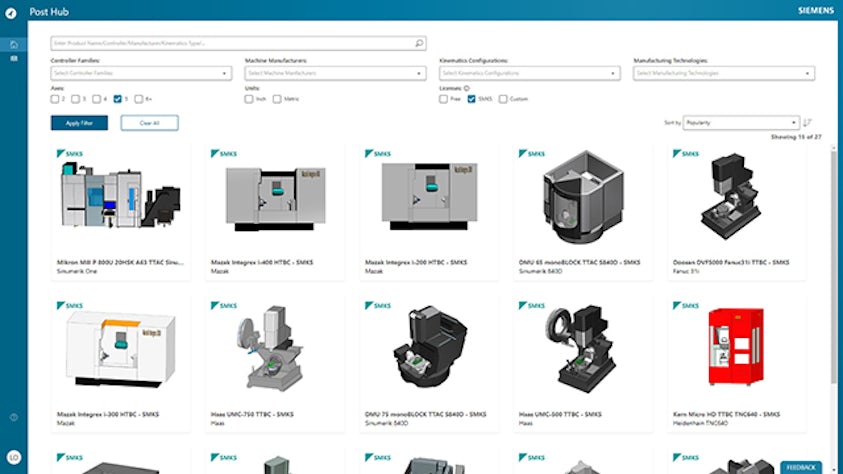

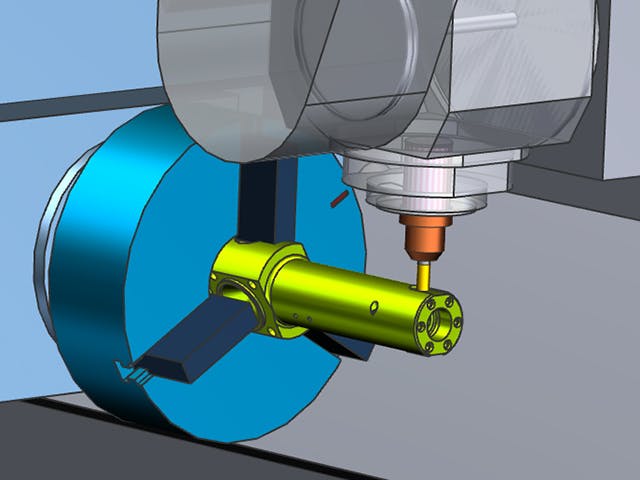

使用基于云的集成后处理和加工仿真输出经验证的机床特定数控程序。使用完整、关联的车间文档(包括工具列表、设置表和 3D 图纸)将制造数据传输到车间。

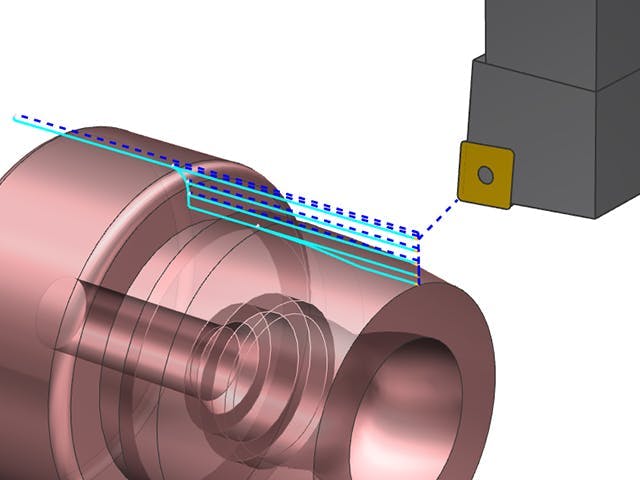

NX CAM 提供 3 轴铣削的高级编程功能,包括:

- 3D 自适应粗加工

- 残料铣削

- 引导曲线精加工

- 深度精加工

- 切削区域控制

- 螺旋和螺旋形精加工

- 在制品 (IPW)

- 刀轨验证

- 后处理

- 车间文档

* 还提供 2.5 轴铣削功能

内置集成式 CAD 工具:

- 同步建模技术

- 装配

- CAD 转换器