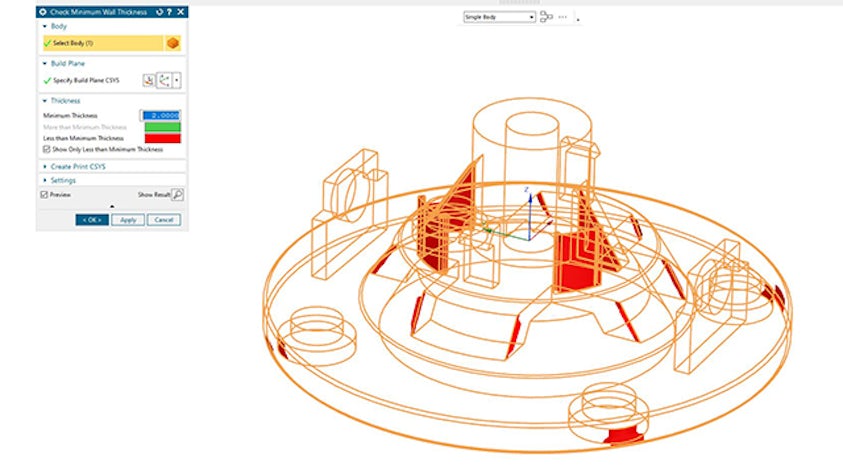

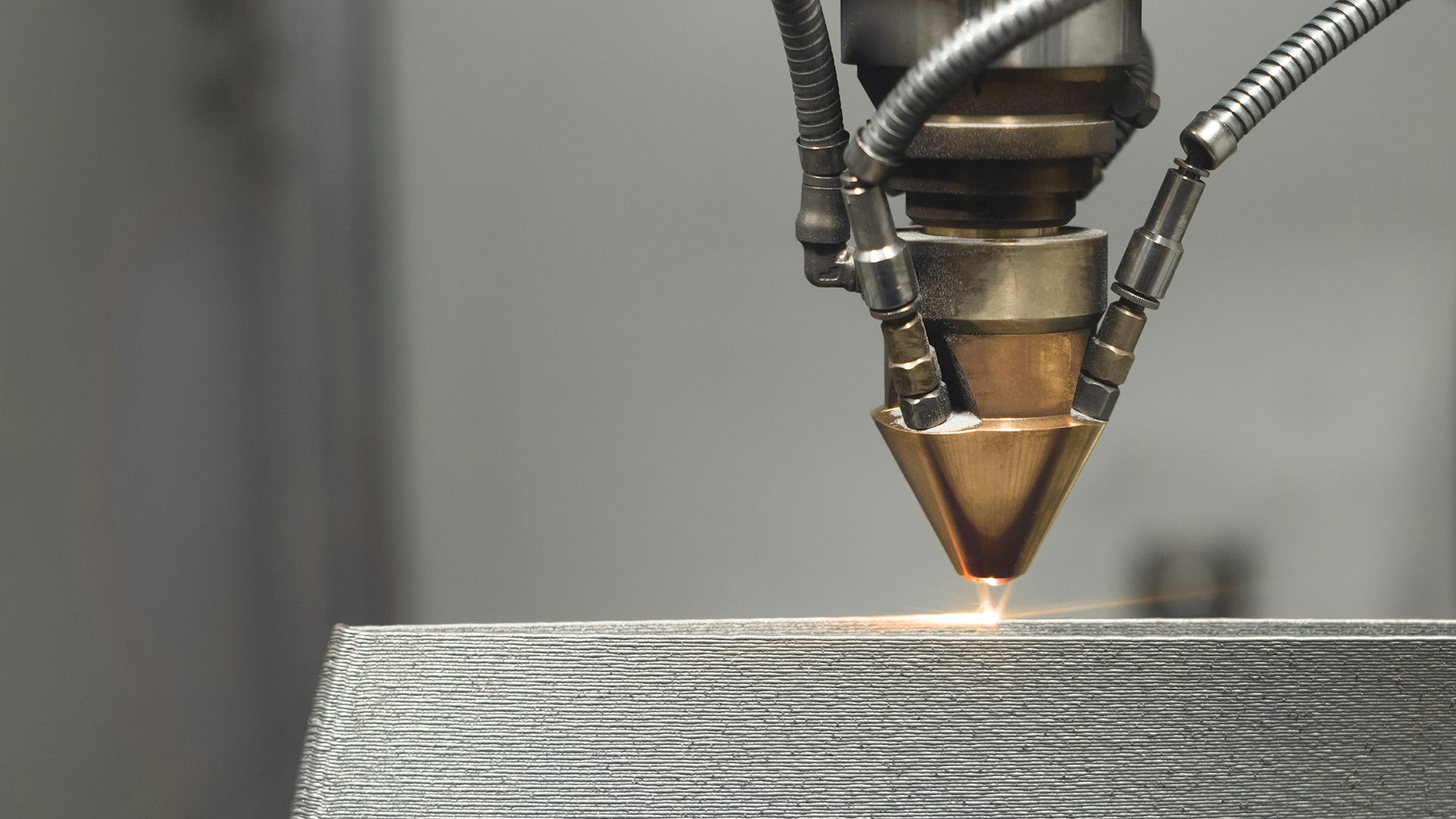

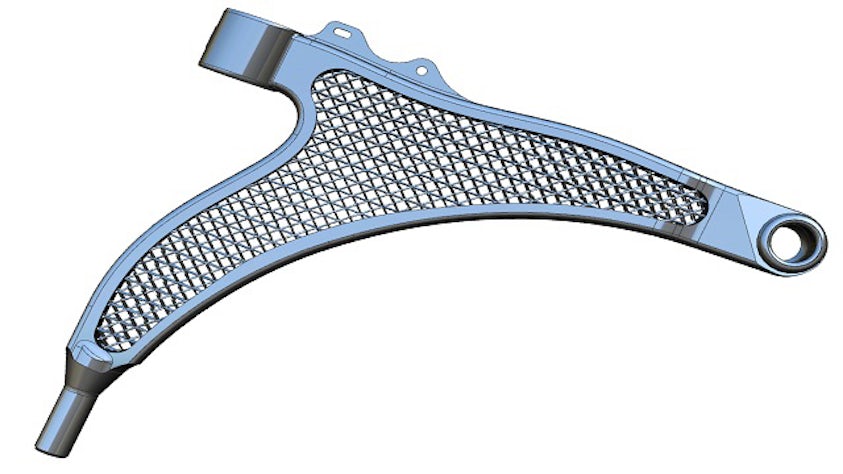

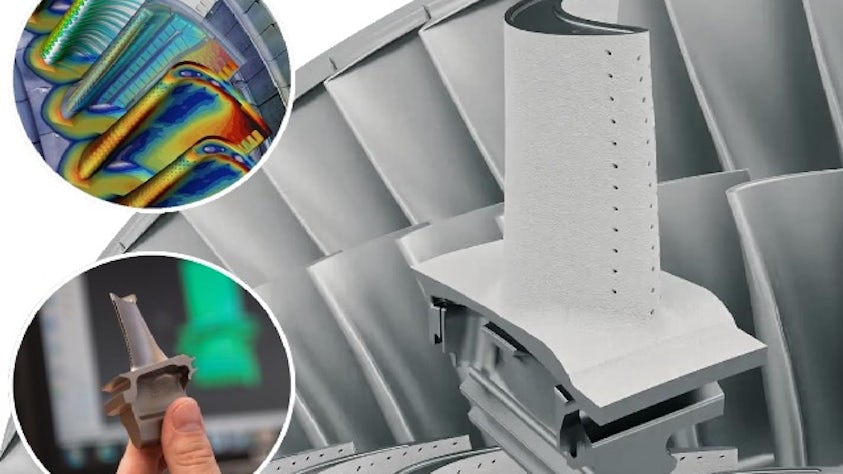

Ensure your product is designed for manufacturability and correctly optimized for performance using additive manufacturing methods. Identify issues such as overhangs, areas that need support, assembly issues and more to deliver products that can be manufactured the first time while saving money and materials used.