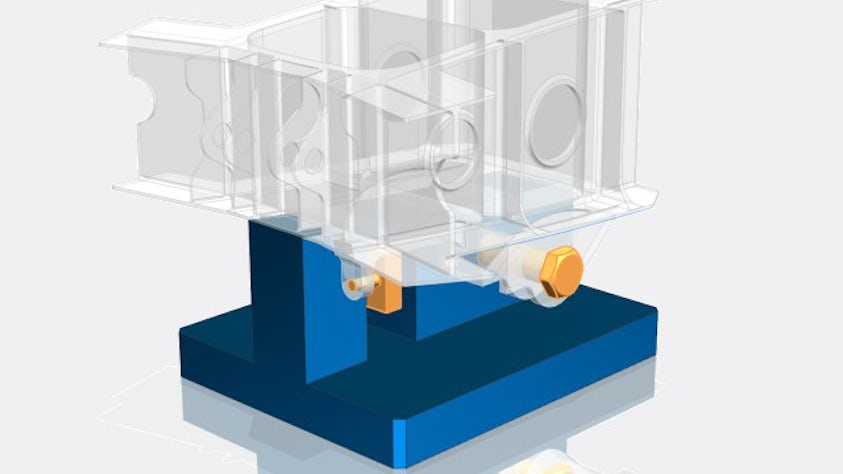

Optimize the design of the most challenging molds using advanced functionality, step-by-step guidance and associativity with part model in order to ensure fast response to design changes and quality molds.

Start designing today with a free trial of NX CAD, a leading product design solution. Learn how to develop high-quality products by using the high-performance design capabilities of NX.

Optimize the design of the most challenging molds using advanced functionality, step-by-step guidance and associativity with part model in order to ensure fast response to design changes and quality molds.

Capture and associate a part's manufacturing requirements directly to the 3D model using product and manufacturing information (PMI). This information, including geometric dimensioning and tolerancing, 3D annotation, surface finish and material specifications, becomes available across the entire operation.

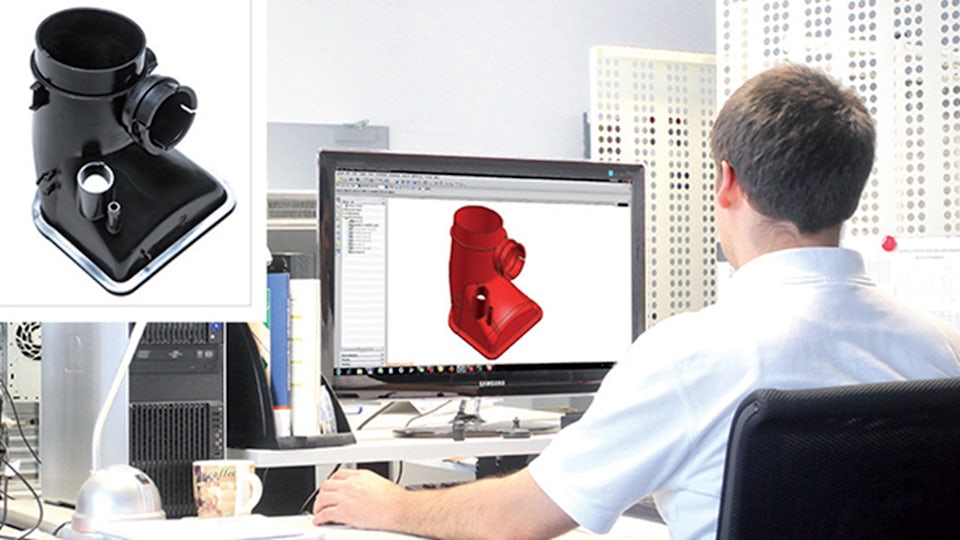

Use the comprehensive CAD functions of NX to model your part from a drawing, modify an existing model or create a job setup assembly.

Facilitate concurrent manufacturing by linking all functions to the single model definition of the part—from part model design and optimization—using master model technology. The toolpaths, job setup assembly and shop documentation update instantaneously when design changes occur.

Automate the design of molds, progressive dies, stamping dies and fixtures using process-based design applications.

Company:Euroform

Industry:Automotive & transportation

Location:Budapest, Hungary

Siemens Software:NX