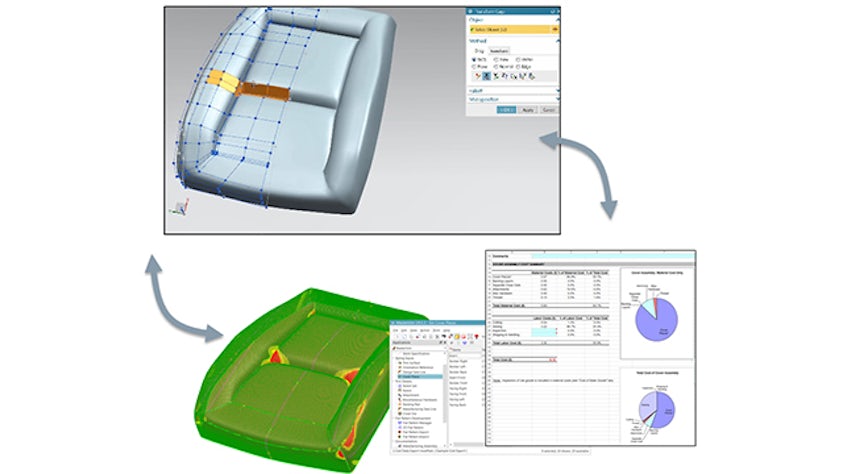

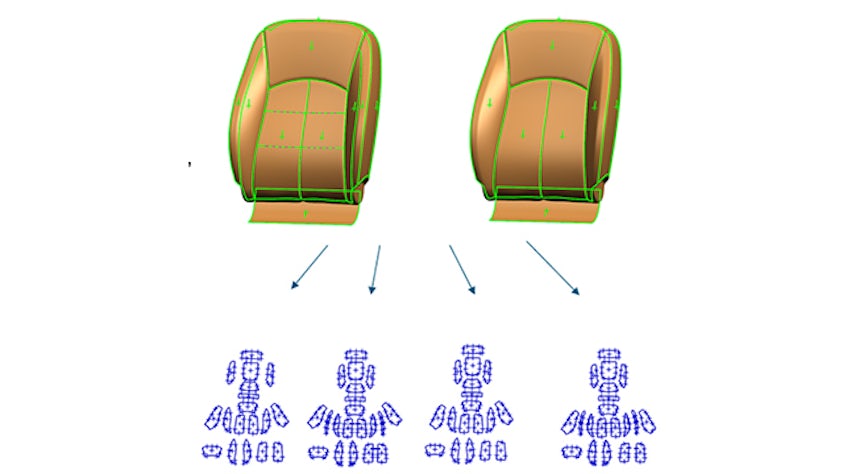

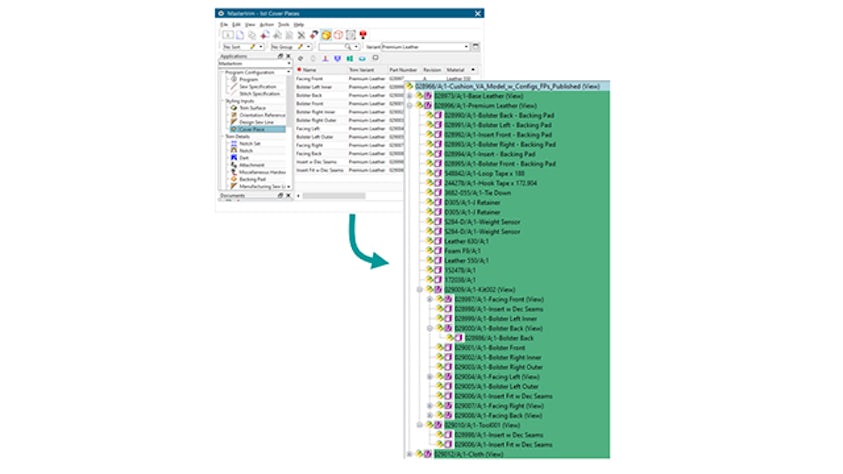

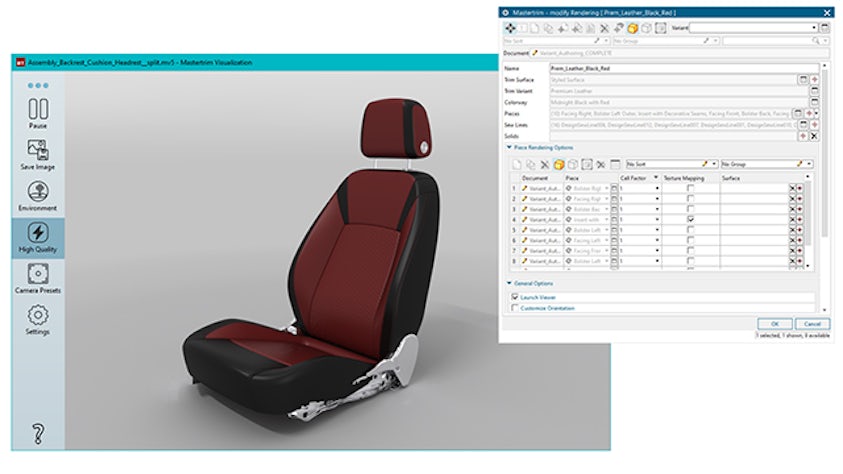

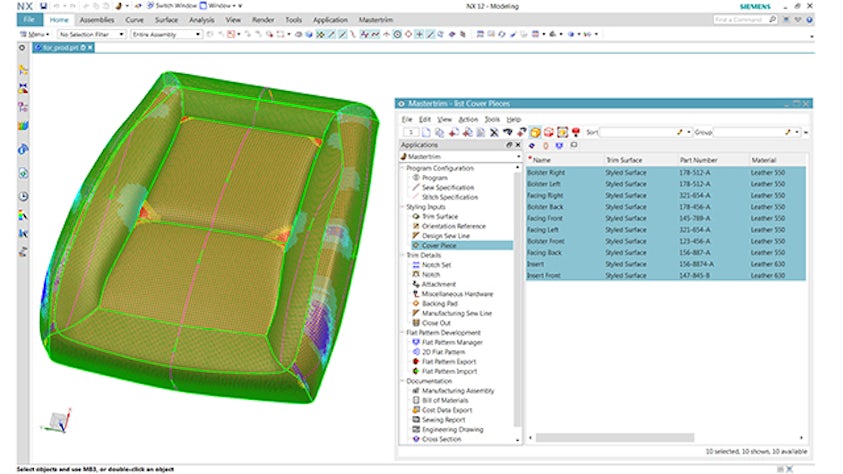

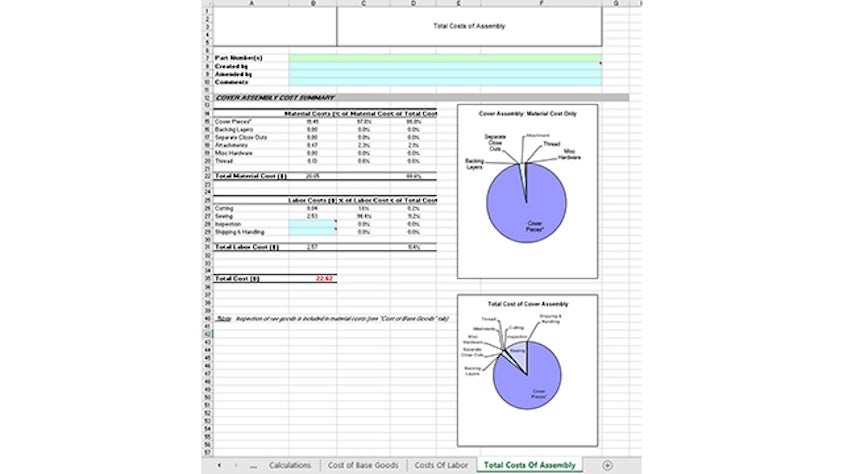

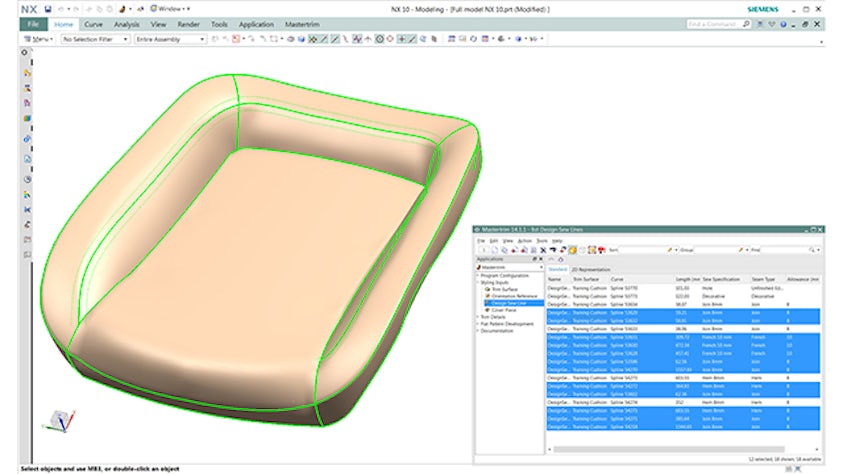

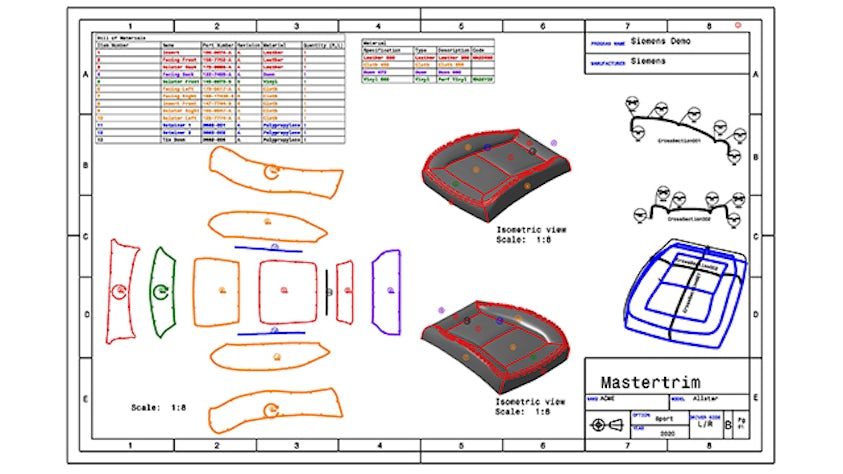

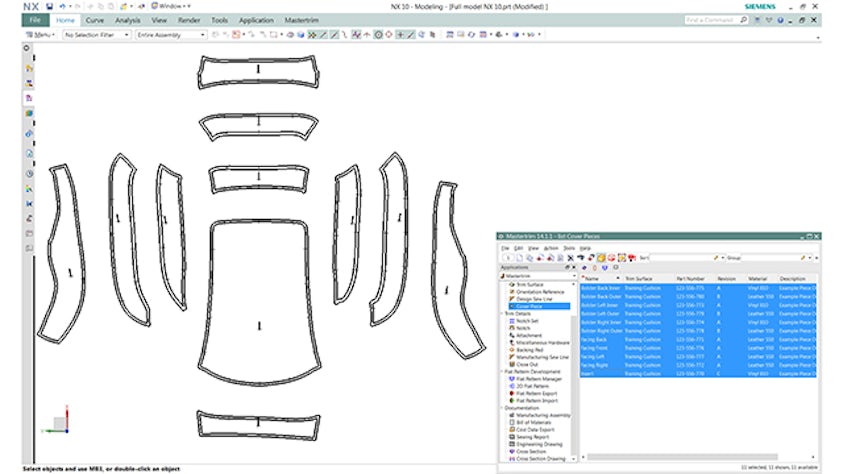

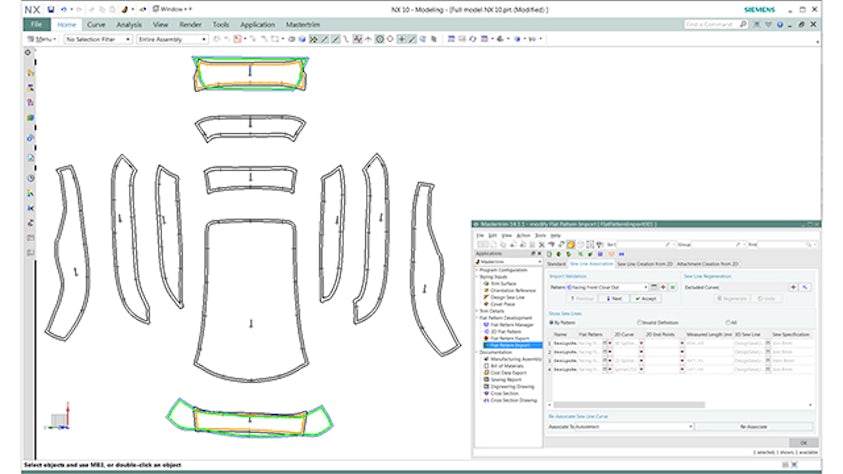

Using Mastertrim for design facilitates the creation of a 3D CAD digital twin by streamlining the task of authoring design data that defines a seat trim cover, including sew lines, cover pieces materials, attachments and hardware.

This enables you to make changes quickly, based on more accurate feedback and efficiently share information throughout the development process.

Mastertrim provides seat trim engineers with the tools needed to:

- Become less reliant on physical prototypes

- Achieve efficiency and accuracy during design, validation, and manufacturing development processes

- Better streamline collaboration and communication between styling, design, and manufacturing, as well as original equipment manufacturers (OEMs) and the supply chain

- Leverage the digital twin to effectively share information throughout the development process