Product analysis

Start the mold design by designing the product. You can open any standard CAD files or select parts designed with NX.

Ensure desired design intent and manufacturability by modeling, making design changes and analyzing geometry.

Rapidly develop high-quality molds using advanced automation while maintaining associativity to part designs.

Start the mold design by designing the product. You can open any standard CAD files or select parts designed with NX.

Ensure desired design intent and manufacturability by modeling, making design changes and analyzing geometry.

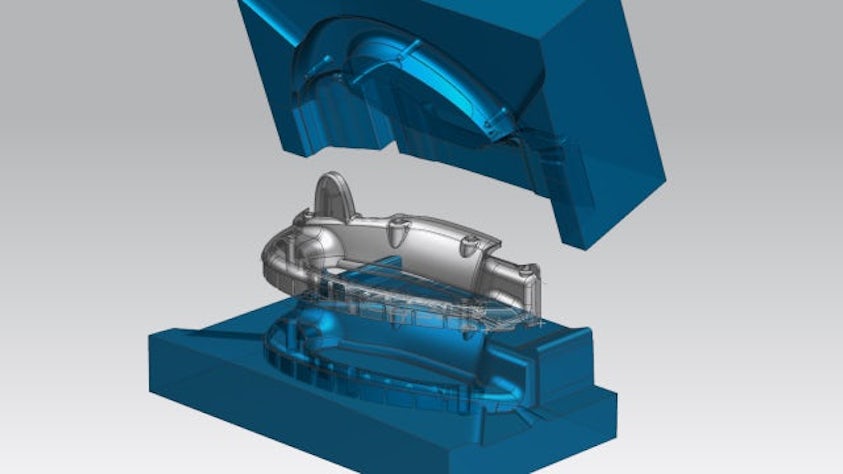

Streamline the design process of core and cavity geometry using automated capabilities, enabling you to:

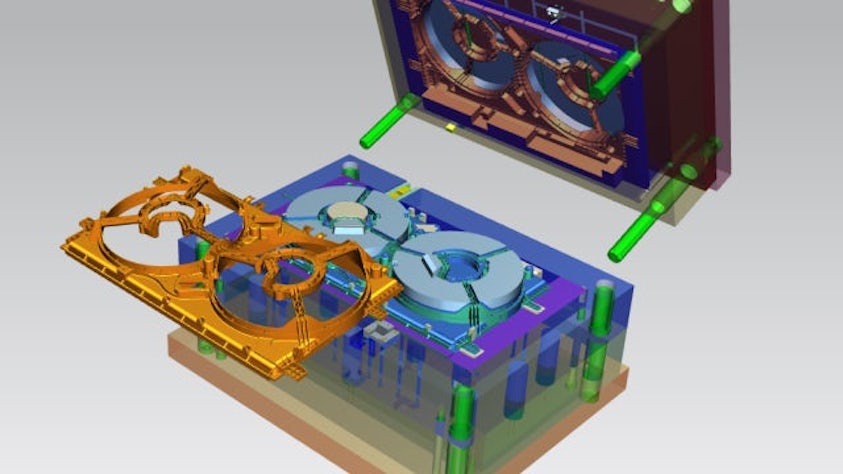

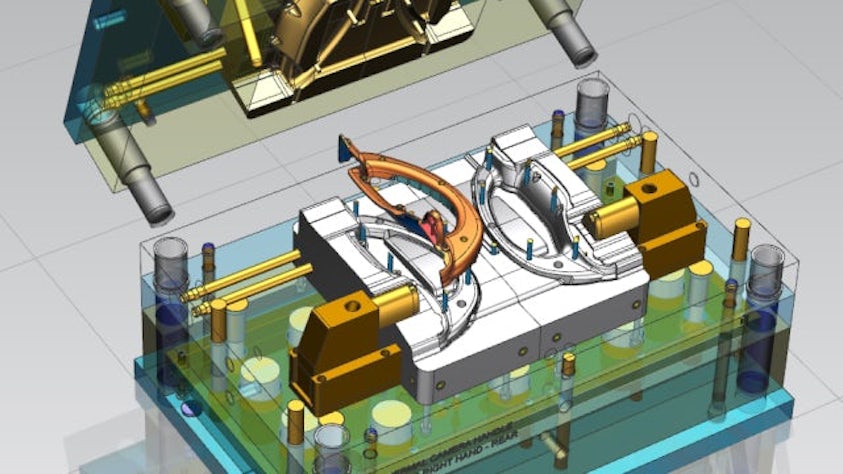

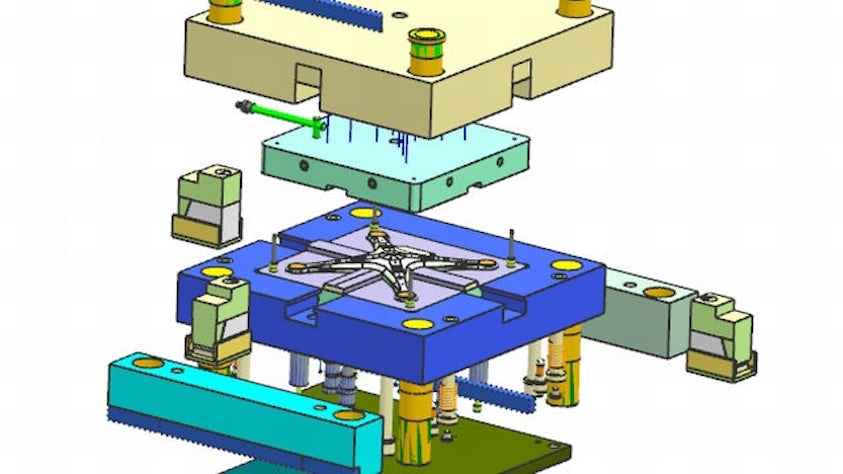

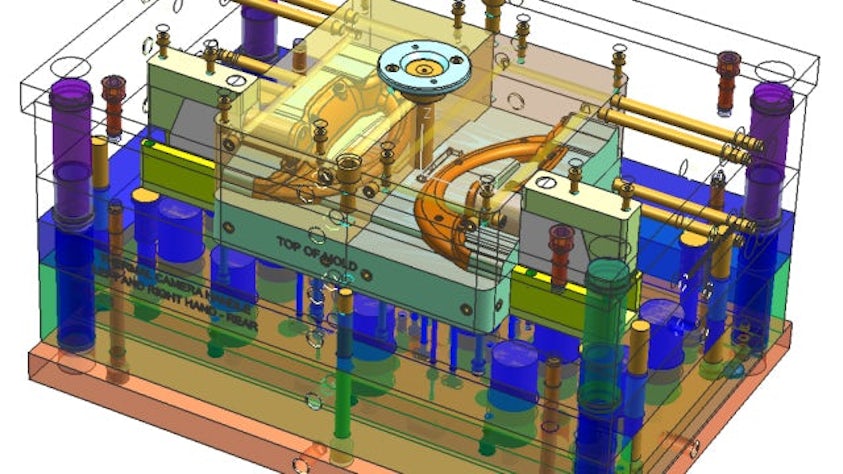

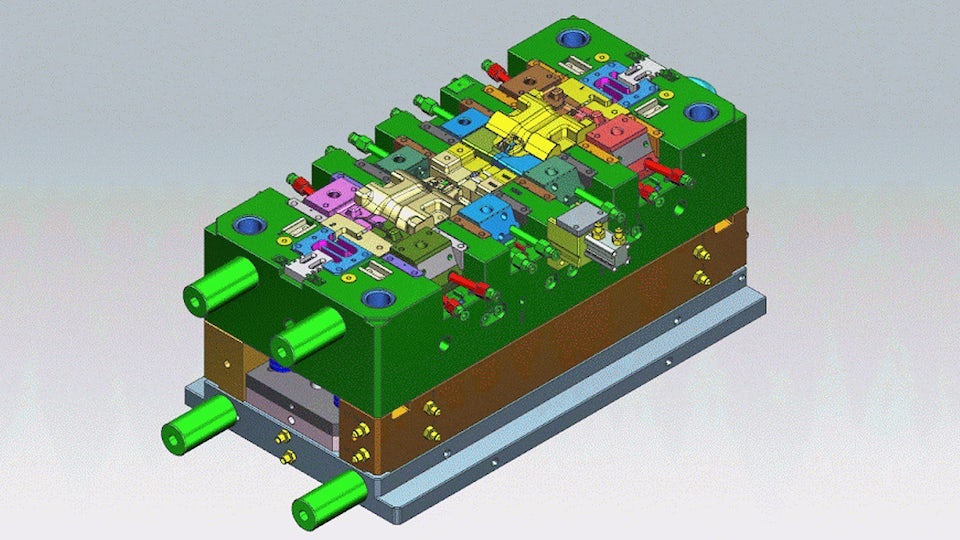

Define the entire mold structure, including the core, cavity, component systems and mold base for both prototype and production-scale multi-cavity molds.

Configure the mold using libraries of standard parts, component systems and mold bases. Quickly add and trim ejector pins and insert cooling channels with parametric patterns. Include runners, gates, screws, pins and other standard components.

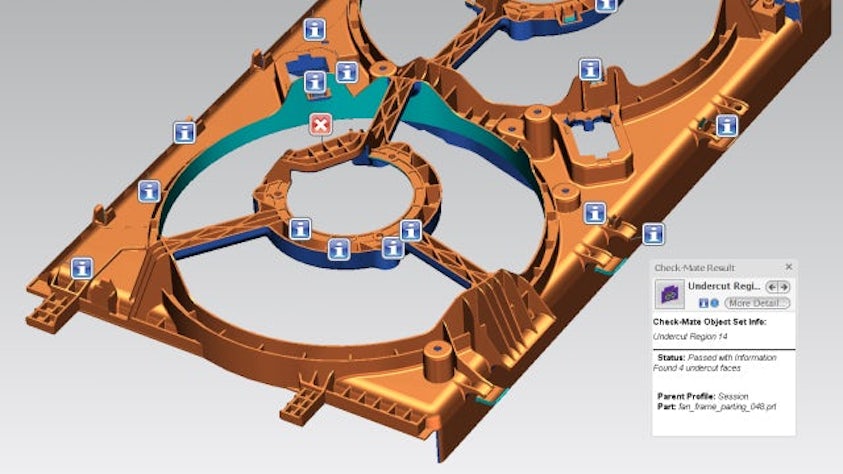

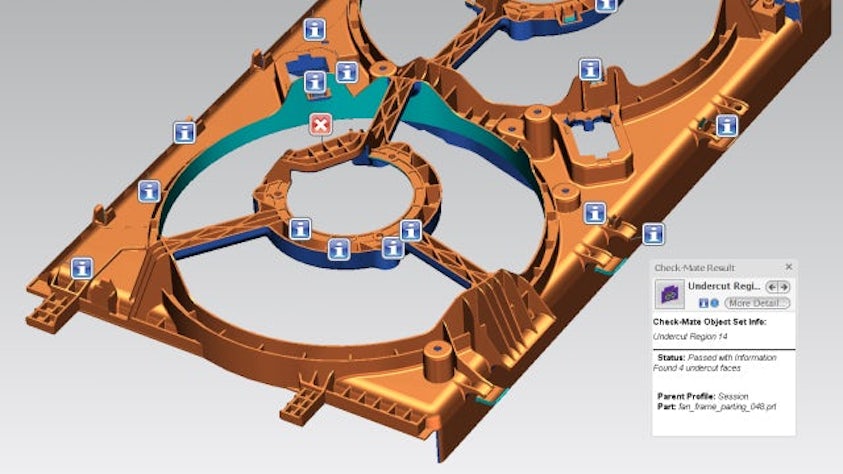

Analyze the manufacturability of part designs using tools to check wall thickness, identify undercut regions and evaluate corner radii.

Validate the mold design by checking the distances and reliefs in various positions and by analyzing the requirements for electrodes.

Use the motion simulation capabilities to verify the entire range of movements of the mold, including dynamic collision detection.

Reduce tool development time by reusing your company's standards, including:

Use the associativity with the part model to facilitate rapid propagation of design changes through the process, from mold design to machining operations.

Ensure that the entire team works with the correct data by integrating the Teamcenter software, which provides a single source of data and process knowledge.

Company:Matrix Tools and Solutions

Industry:Industrial machinery

Location:Pune, India

Siemens Software:NX

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.