Connected manufacturing to improve your business

Get into production faster with Teamcenter manufacturing process planning and data management. Collaborate instantly and securely to optimize part production and assembly operations. Execute all related activities more efficiently with a digital thread that spans your organization and plants.

Manage manufacturing processes in the cloud

SaaS manufacturing process management is available in the cloud, managed for you by Siemens experts. Get started right away with preconfigured best practices. Get continuity of manufacturing information with secure data exchange and process visibility. Connect your engineering and manufacturing engineers, planners, shop floor users, partners and suppliers, line builders, design houses and more.

Plan and manage your manufacturing processes – easily

Create and manage manufacturing bill of materials (MBOM) and bill of process (BOP) data to understand what to make and how. Teamcenter, integrated with Siemens' digital manufacturing solutions, makes collaboration between engineering, manufacturing and execution easy. Reuse assembly processes across plants, author and share work instructions to the shop floor, perform time analysis and line balancing and more.

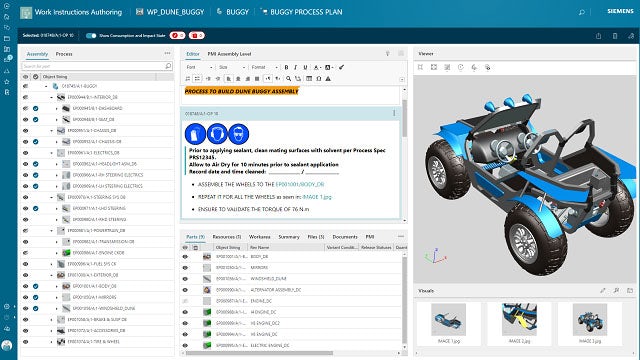

Author and share electronic work instructions

Create comprehensive manufacturing work instructions for greater clarity of process steps on the shop floor. Deliver the most up-to-date information, and clearly demonstrate the bill of process steps using 2D and 3D visualization tools, and AR technology. Process documentation is automatically updated through revision management, so you can react to changes quickly and easily, both before and during production.

Create and maintain the bill of process (BOP)

Create processes and operations within the BOP for the sequence of steps in assembly plans. Assign relevant parts and assemblies from the MBOM to operations, specifying required tools and resources from the bill of equipment (BOE), or through a library of classified objects. Streamline changes from product engineering into the BOP using accountability check tools to keep engineering and manufacturing in sync.

Reconcile engineering and manufacturing BOMs with ease

Quickly update assembly process plans according to design changes, using the integrated product and process development platform in Teamcenter. The BOM accountability check tools help product and manufacturing engineers quickly visualize and validate the impact of any product and process changes. This avoids expensive, late-stage identification of issues in production.

Estimate operation times and perform line balancing

Time management and balancing solutions give visibility into value-add and non-value-add manufacturing process activities. Time analysis uses time standards, such as MTM, with an embedded integration to TiCon. Line balancing displays visual time roll-ups for operations, stations and operators. Optimize the plan to a target Takt time, improve the operator work in the line and evaluate alternative plans.

Optimize planning to production with part manufacturing

Transform your machine shop into a data-driven operation with product design and assembly planning information in one system. Optimize your production processes with part planning, connection to the shop floor and a manufacturing resource library.

Manage manufacturing resources digitally

Quickly find what you need and efficiently manage your manufacturing resources with powerful search and retrieval capabilities across a full classification system. Providing pre-loaded cutting tool data, the manufacturing resource library (MRL) can be accessed directly from within NX CAM. You can create tool assemblies or import data from tool vendor catalogs.

Connect to the shop floor

Use a single platform to connect planning and production. Deliver the correct data directly to your manufacturing equipment, including CNC machines, CMMs, and robots. Communicate your complete manufacturing process plans across functional domains. Be clear about what, how, and where products are manufactured. Make sure all stakeholders know what resources are needed.

Next-generation collaboration with Teamcenter Share

Optimize your production and manufacturing processes with Teamcenter Share, a cloud-based collaboration solution with a seamless connection to Teamcenter Easy Plan software. Extend the reach of manufacturing planning-related data and processes beyond your internal teams to work smarter and accelerate innovation.