Plant Simulation X Essentials is a powerful, entry-level digital manufacturing solution that features core statistical simulation capabilities to create, analyze and optimize 3D models of production systems and their processes using basic objects, user-defined objects, libraries and controls for up to 500 objects.

Key features

Simulate, validate and optimize

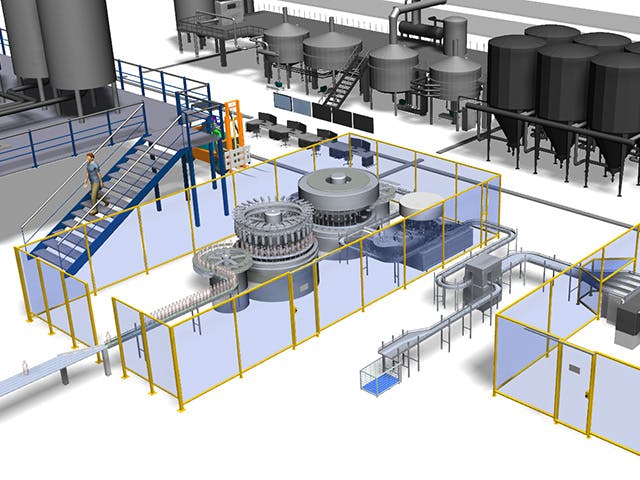

Create 3D visualization models up to 500 objects in size for simulation, validation and optimization of your production systems and processes using Plant Simulation Essentials software. Optimize material flow, resource utilization and logistics for all levels of plant planning—from global production facilities and local plants to specific lines.

Explore and analyze

Accurately model logistics and production systems to explore their characteristics and optimize their performance. The digital model enables you to run experiments and what-if scenarios without disturbing your existing production system or—when used in the planning process—long before the real system is installed. Extensive analysis tools, statistics and charts let you evaluate different manufacturing scenarios and make fast, reliable decisions in the early stages of production planning. Validate part routing and gain a comprehensive view of machine states, facilitating better decision-making and production management.

Streamline data exchange

Leverage integration with technologies like ActiveX, C-Interface, MQTT, ODBC, OPC UA, PLCSIM Advanced, SIMIT, SQL for Oracle, and Socket to enable direct access to third-party code, database integration, and efficient data transfer, enhancing real-time simulation and monitoring.

About Plant Simulation X

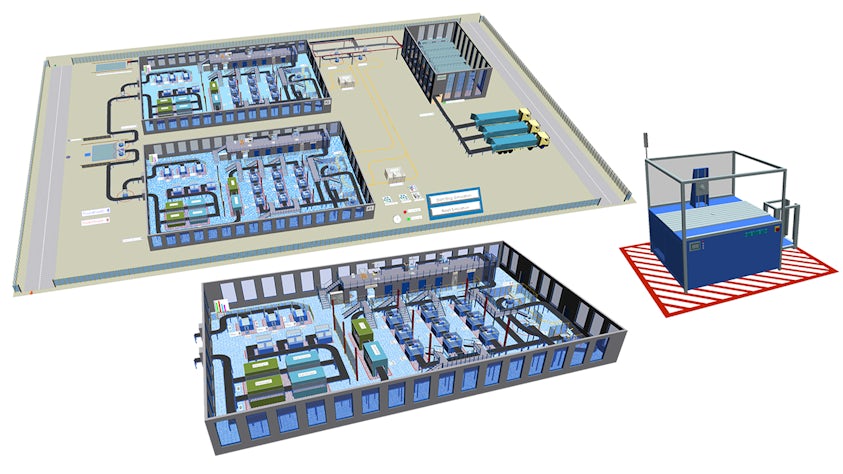

Plant Simulation X is a software-as-a-service (SaaS) solution with extensive digital manufacturing capabilities used to simulate, explore, analyze and optimize production and logistics at all levels of planning. Access hierarchical models of production facilities, lines and operations in a 3D environment with the added benefits of flexibility, collaboration, security and scalability of a cloud-based software.

The streamlined software deployment and configuration enables higher productivity and immediate expansion of your manufacturing capabilities. The cost-effective and customizable Plant Simulation X products are tailored for different levels of digital manufacturing complexity.

Benefits of Plant Simulation X:

- Optimize the performance and energy usage of existing production systems before implementation

- Maximize efficiency and utilization of resources and identify bottlenecks during the planning phase

- Improve productivity and minimize the investment cost of production lines

- Enhance collaboration among stakeholders using cloud-based solutions