Enable an intuitive user experience and ease of use for assembly process planning that helps to standardize and reuse best practices. Develop manufacturing process plans that reflect plant-level production scenarios, and leverage strong configuration and change management for manufacturing data. Optimize cycle times and production rates and provide clear and up-to-date operator instructions.

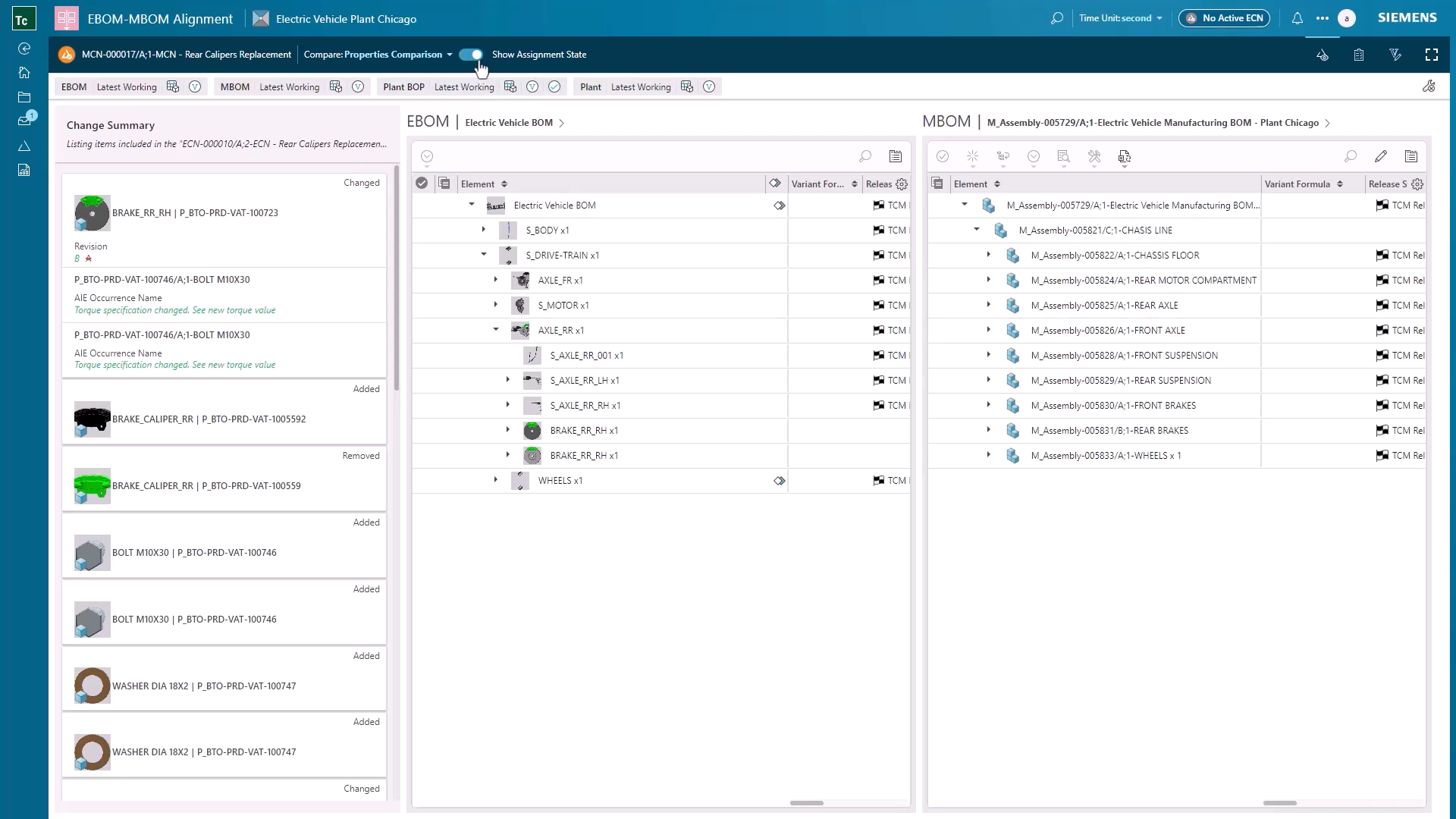

Manage manufacturing BOMs

Increase accuracy and reduce inventory costs as changes are implemented with MBOM management on the same PLM backbone and reconciled with your engineering bill of materials (EBOM).

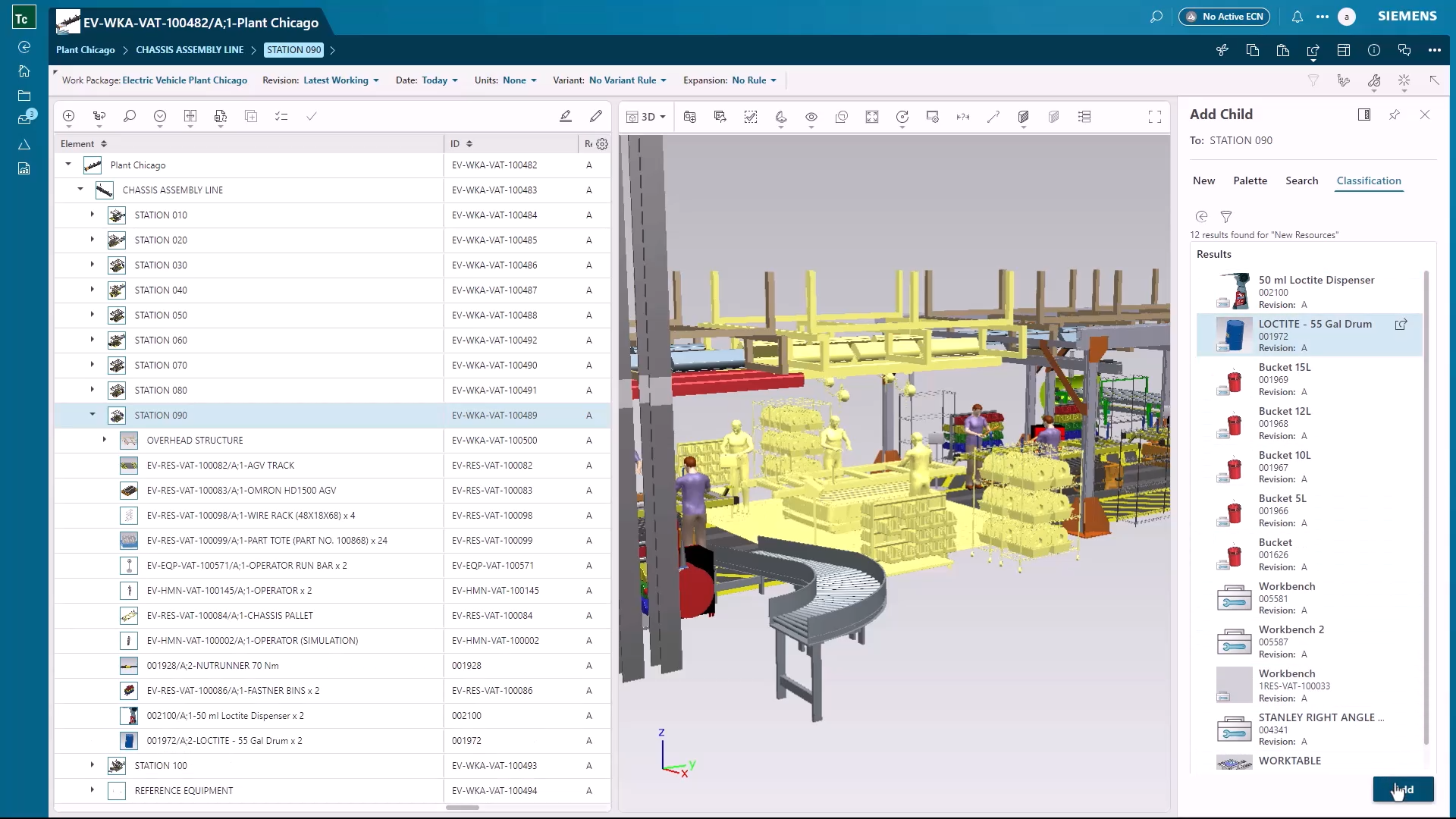

Validate process plan details

Accelerate new product introduction (NPI) and improve quality with streamlined definition and management of your BOP integrated with manufacturing engineering. Validate your process plans much earlier in the production lifecycle to reduce late design changes.

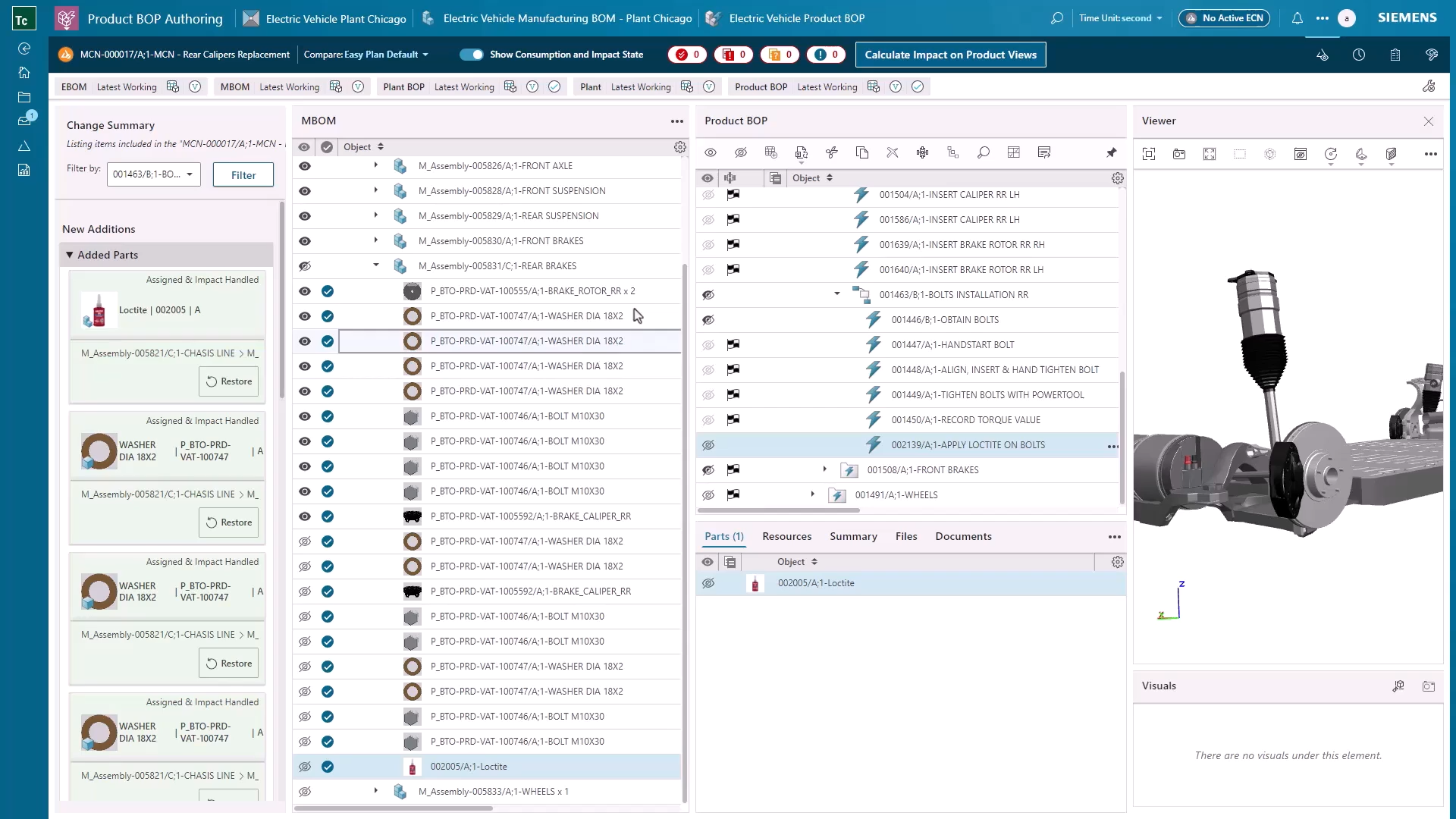

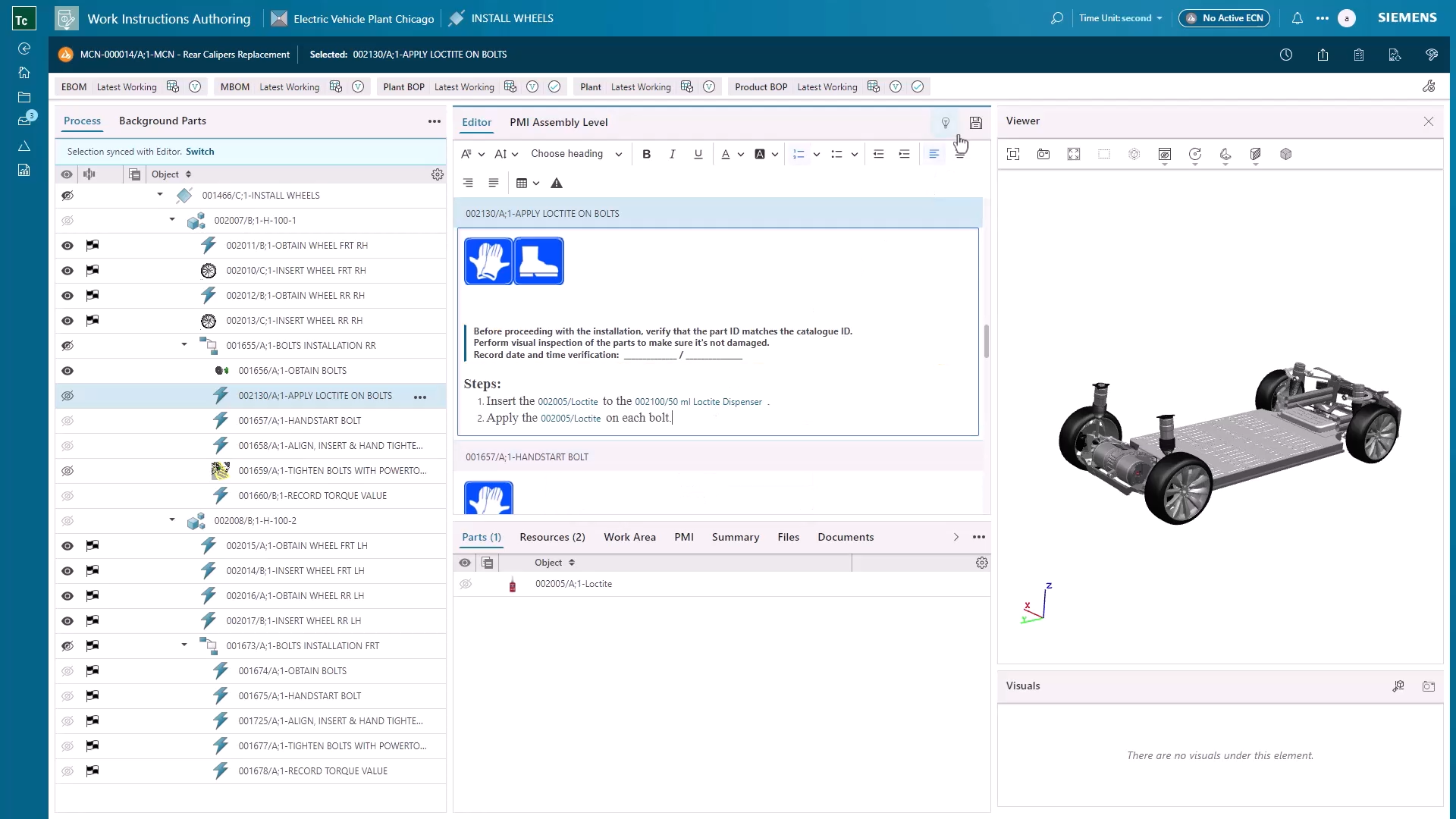

Deliver work instructions to the shop floor

Reduce costs of errors on the shop floor with a task-oriented environment to easily author work instructions based on the MBOM and process plan. Intuitive work instructions with visual aids, including augmented reality (AR), are delivered seamlessly to the shop floor.

Access key features

- EBOM and MBOM accountability, reconciliation and visualization

- Configuration using variants and effectivity

- Operation time analysis and line balancing

- Cycle time and production rate estimation

- Textual work instructions and visual aids with markups

- Issue reporting and guided change management