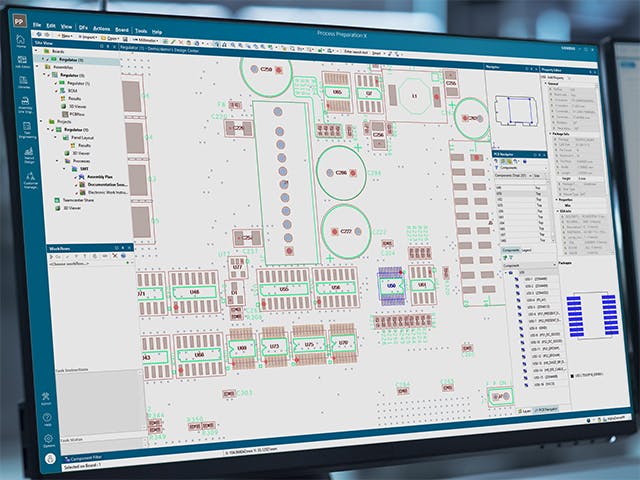

Optimize Electronics Manufacturing with Smart Process Preparation

Process Preparation X is a comprehensive process planning platform designed to accelerate high-mix, low-volume electronics production. By leveraging advanced SMT programming, it enables seamless global engineering while reducing complexity and the total cost of ownership. With Process Preparation X, manufacturers gain a secure, future-proof technology suite that streamlines workflows, minimizes manual errors and adapts effortlessly to any machine setup.

By leveraging advanced SMT programming for automated machining, manufacturers can enable seamless global engineering while reducing complexity and the total cost of ownership. With Process Preparation X, manufacturers gain a secure, future-proof technology suite that streamlines production workflows, minimizes manual errors and adapts effortlessly to any SMT machine setup.