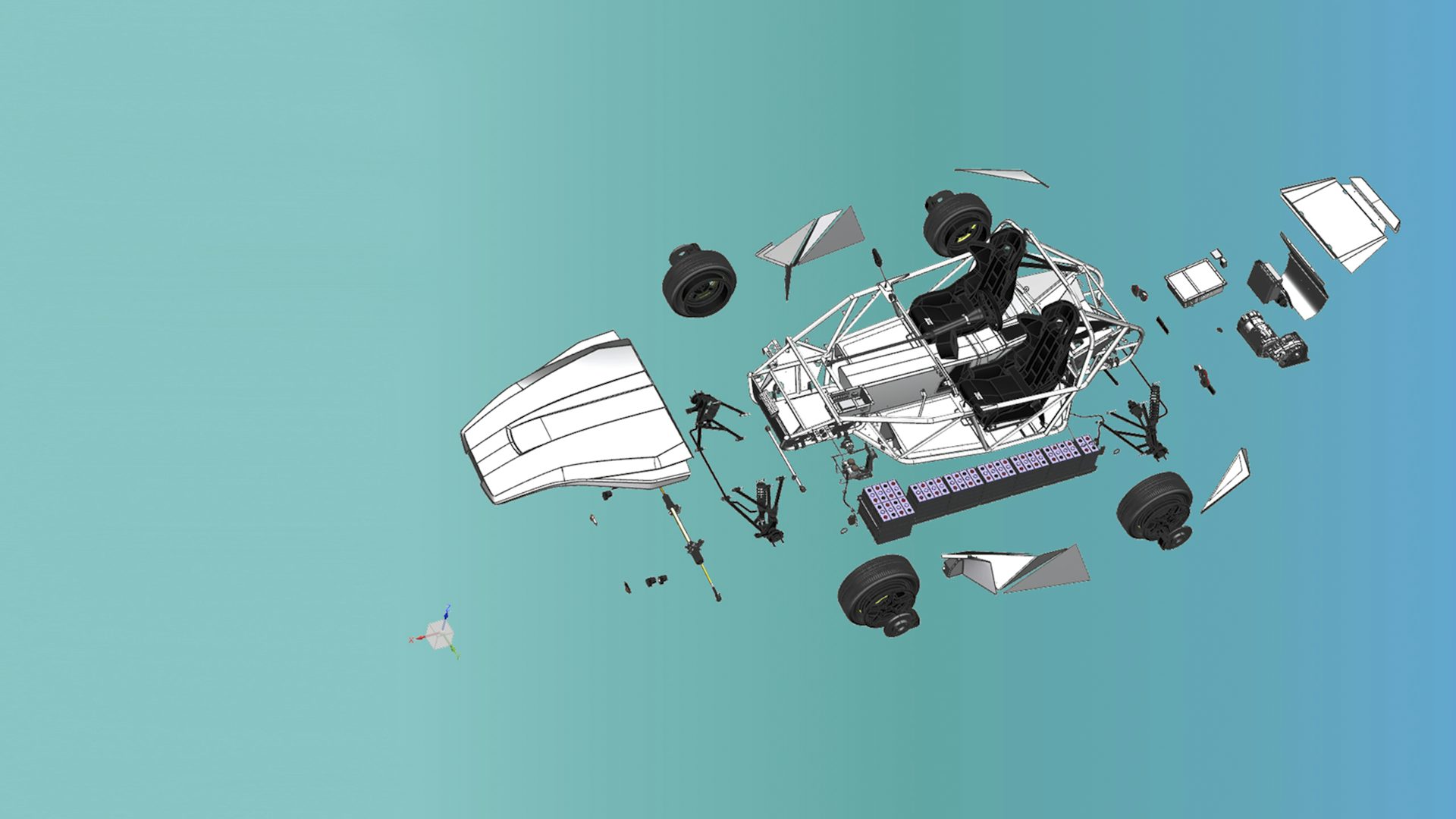

Dans toutes les industries, des stratégies de plateforme sont établies en réutilisant des composants complexes dans toutes les variantes de produits et la disponibilité du prototype de produit pour les tests et l'évaluation des performances NVH est considérablement réduite. En outre, il y a le passage à la propulsion électrique dans l'industrie automobile : les ingénieurs doivent étudier de nouveaux concepts de groupes motopropulseurs avec des cas de charge complexes et doivent tenir compte de l'importance accrue du bruit routier et des sources de bruit secondaires.

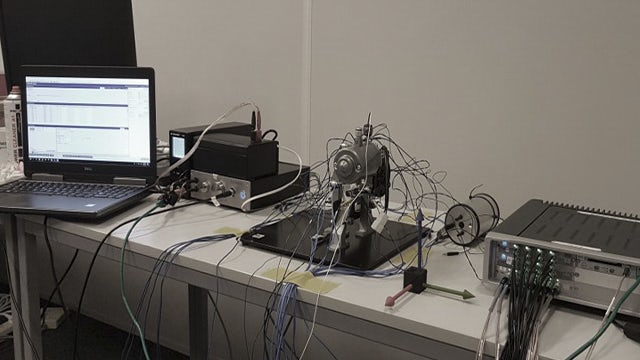

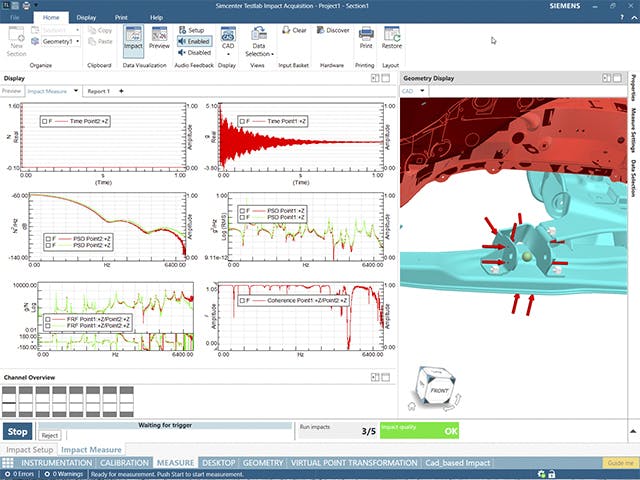

L’analyse de chemins de transfert (TPA) basée sur les composants est une technologie qui relève ces défis. Elle permet de modéliser un composant source de bruit indépendamment de la structure du récepteur et de prédire son comportement lorsqu'il est couplé à différents récepteurs. Cela concentre le développement en début de période qui augmente considérablement la flexibilité de conception. La méthode permet aux fournisseurs de composants de caractériser leur produit indépendamment du produit récepteur et de prédire l'interaction de l'interface avec la structure de réception et le confort sonore du produit final.

Le résultat net évite un dépannage tardif, ainsi que des activités de dépannage et des modifications de conception coûteuses. Il contribue également à la persévérance des connaissances puisque les connaissances d'experts clés sont intégrées dans un processus de développement basé sur des modèles.