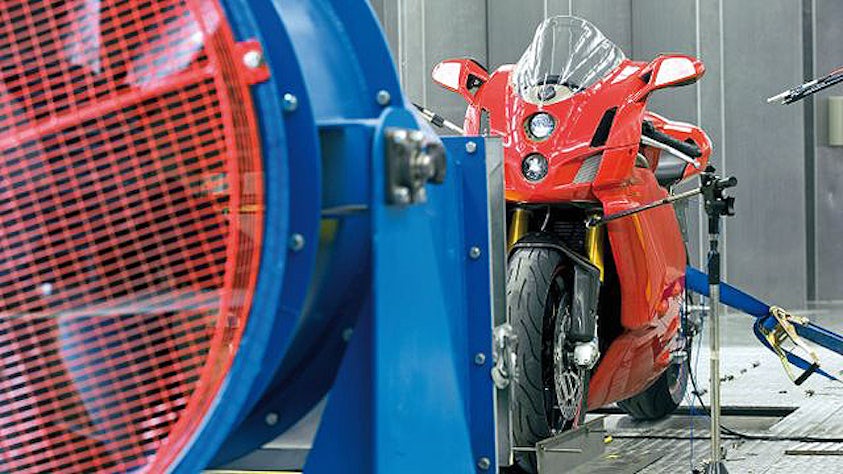

試験効率を高め、より信頼性の高い結果を提供します。Simcenter Testlabソフトウェア・スイートは、Simcenter SCADASデータ収集ハードウェア・システムとシームレスに統合されています。性能エンジニアリングにおける課題に対応するために、将来を見据えた投資としてや、より俊敏でスケーラブルで柔軟な長期的ソリューションとして活用いただけます。騒音・振動・耐久性を扱うエンジニアの広範な試験要件に対応できます。

組込みワークフローで生産性を向上

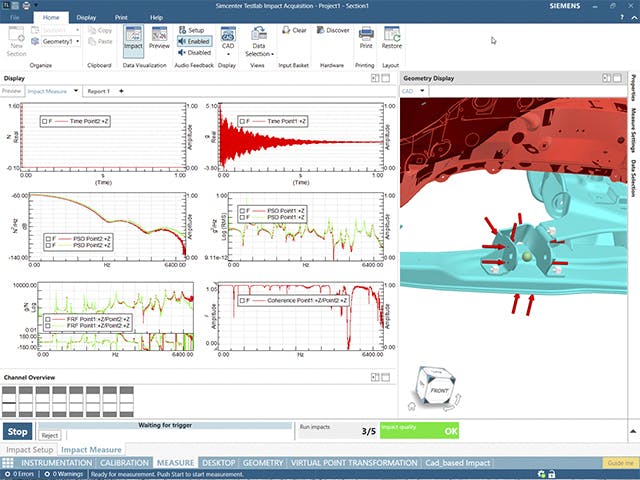

Simcenter Testlabは、独自のワークフローベースのインターフェースを採用しており、使いやすさ、生産性、データの整合性の新しい基準を打ち立てます。示される手順に従って操作し、測定と解析に最適な推奨値を活用して、一連の試験内容を実施できます。他のアプリケーションとのデータ共有もシームレスに行われるため、非常に効率的です。データ収集と同時に解析が行われるため、試験が短時間で終了し、最適なデータ品質が保証されます。

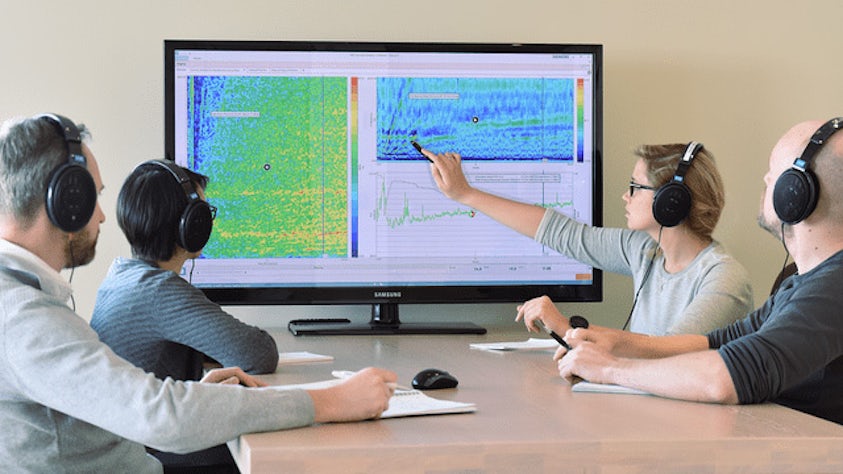

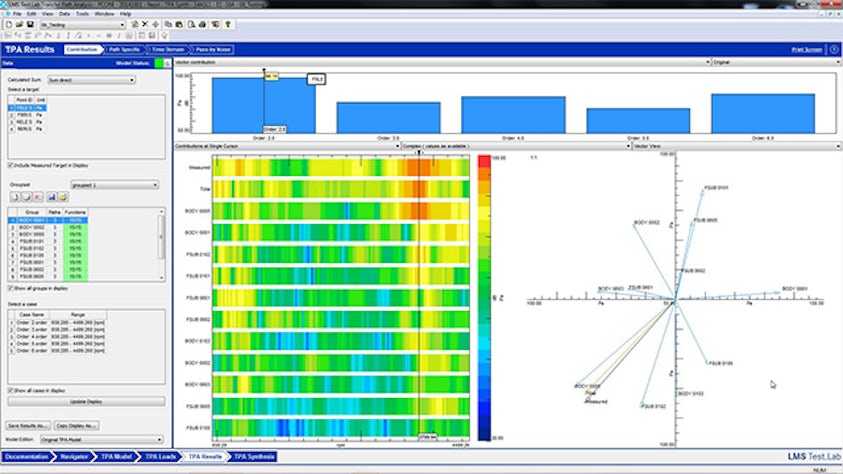

騒音や振動の問題の発生源を瞬時に特定

Simcenter Testlabが示す手順に従って包括的な解析機能を使用すれば、問題の発生源を即座に特定することができます。試験担当チームは、設計上の問題を効率的に調査し、問題の根本原因を直接突止めることができます。扱いやすいwhat-if解析機能が用意されているため、解決策候補をすぐに評価し、効率的かつコスト効果の高い形で問題を迅速に解決できます。

変化する試験の世界における可能性の実現

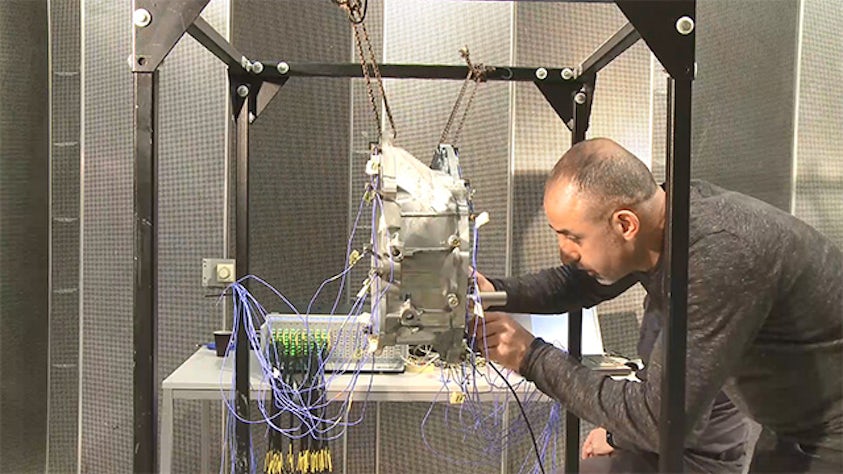

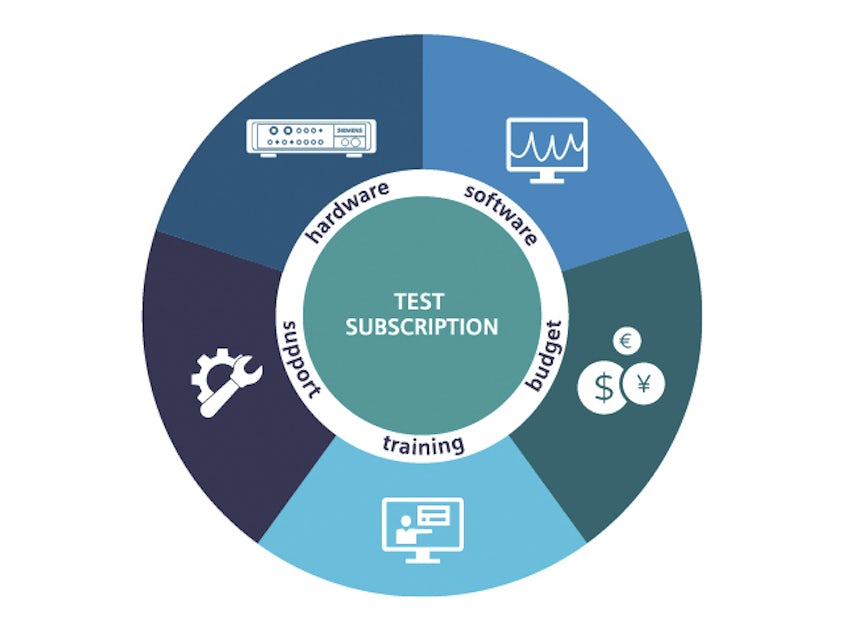

Simcenter Testlabの広く使用されている機能として、既存のコンポーネントを試験し、競合製品のベンチマークを行うことで、これらのデータをシミュレーション・プロセスの初期段階から活用することができます。また、情報を読み込み、フィードバックすることで仮想モデルを更新します。さらに、複雑すぎて仮想的にモデリングできないコンポーネントとサブアセンブリのために、Simcenter Testlabを体系的に使用して試験由来のモデルを提供することができます。Simcenter Amesimソフトウェアに簡単に統合できるSimceter Testlabソフトウェアは、効率的かつ現実的な仮想シミュレーションを行うために不可欠な存在です。Simcenter Testlabのライセンスは、購入、1年以上のサブスクリプション、実際のニーズに合わせてソフトウェアの使用を拡張できるバリューベースライセンスの3つのオプションにより、試験ユーザーの生産性を向上させるために必要な柔軟性を提供します。

Simcenter Testlabを使用して試験を効率化し、製品イノベーションを加速

ウェビナーで、データ収集、解析、モデリング用ソフトウェアであるSimcenter Testlabを使用して直近のエンジニアリング課題を克服することで、製造の効率化と製品イノベーションを加速する方法をご紹介します。