Boost testing efficiency and deliver more reliable results. The Simcenter Testlab software suite is seamlessly integrated with Simcenter SCADAS data acquisition hardware systems and can be a future-proof investment or a more agile, scalable and flexible time-termed solution to respond to your performance engineering challenges. It covers the extensive testing requirements of noise and vibration and durability engineers.

Improve productivity with in-built workflows

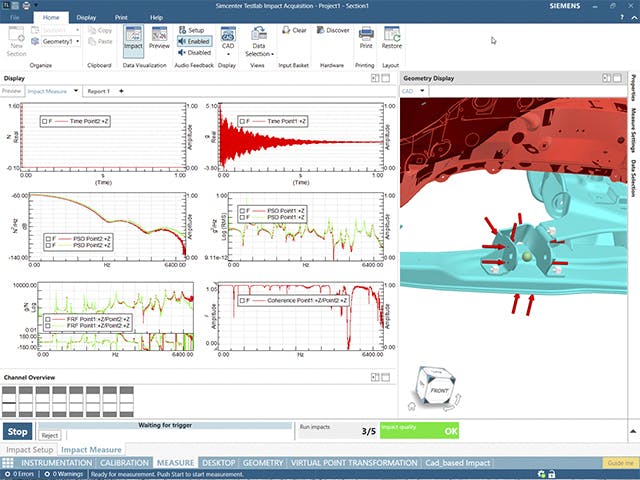

With its unique workflow-based interface, Simcenter Testlab sets new standards for ease of use, productivity and data consistency. The software guides the user through the steps of the test campaign, suggesting optimal settings for measurement and analysis. Seamless data sharing between different applications delivers tremendous efficiency gains. Embedded analysis during acquisition accelerates the testing process and guarantees optimal data quality.

Travel straight to the source of noise and vibration issues

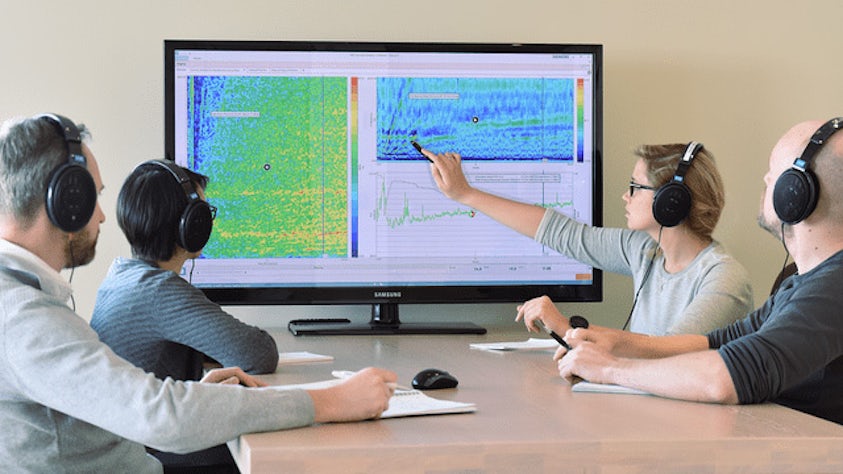

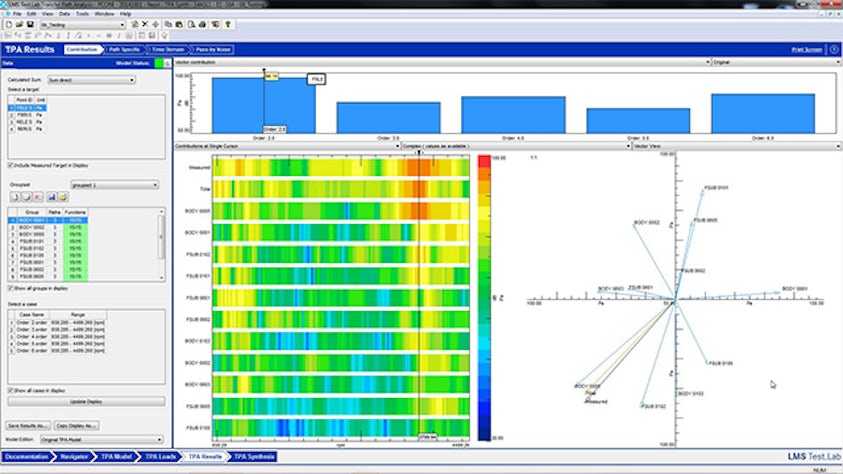

Simcenter Testlab guides users directly to the source of the problem using comprehensive analysis capabilities. It enables testing teams to efficiently troubleshoot design problems and trace the root cause of a problem directly to the source. It supports easy what-if analyses to quickly evaluate possible fixes and solve the problem effectively, cost-efficiently and quickly.

Realize the potential in the changing world of testing

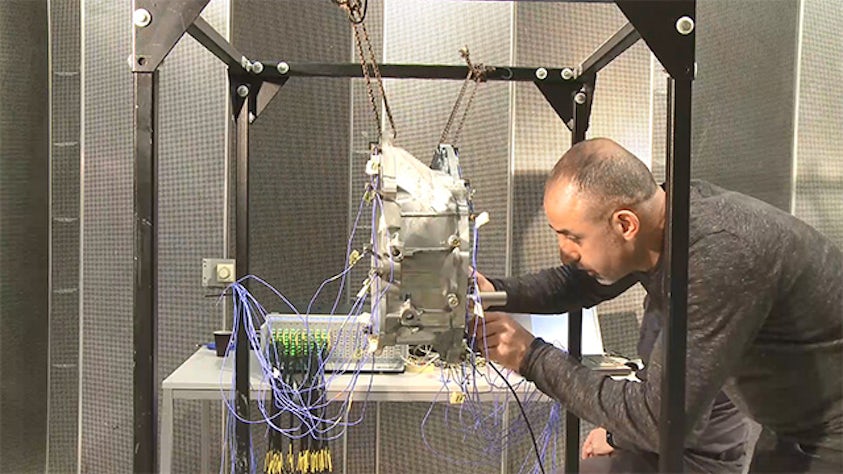

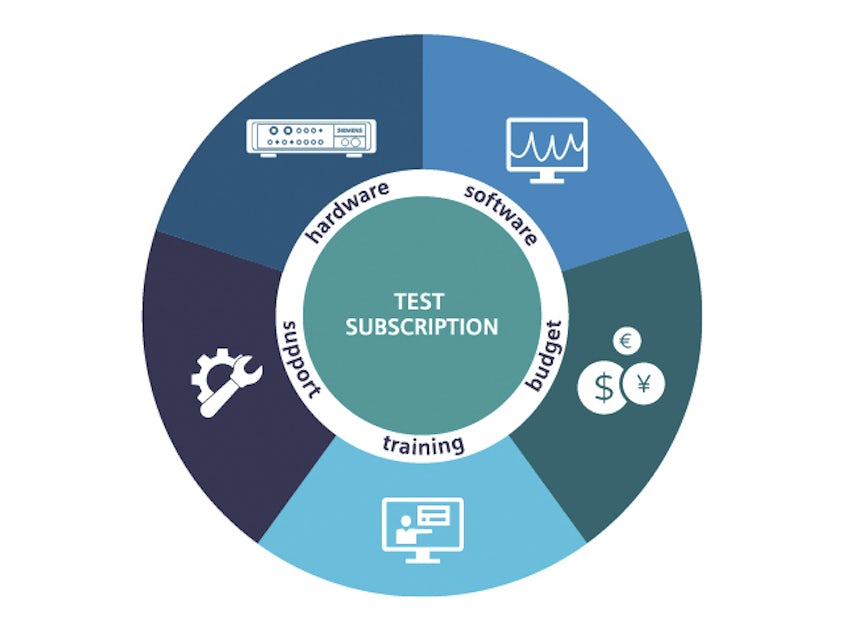

By testing existing components and benchmarking competitive products, Simcenter Testlab is extensively used to frontload data into the simulation process. It also provides loading information and feedback to update virtual models. It is systematically used to provide test-derived models for components and subassemblies that are too complex to model virtually. Easy to integrate into Simcenter Amesim software, Simcenter Testlab software provides critical support for making virtual simulation efficient and realistic. Simcenter Testlab licensing options provide the flexibility needed to increase test users’ productivity with options to purchase, subscribe for a year or longer and scale your software usage to your actual needs through value based licensing.

Boost testing efficiency and product innovation with Simcenter Testlab

Learn how to boost efficiency and product innovation, tackling modern-day engineering challenges using Simcenter Testlab—the software for data collection, analytics and modeling.