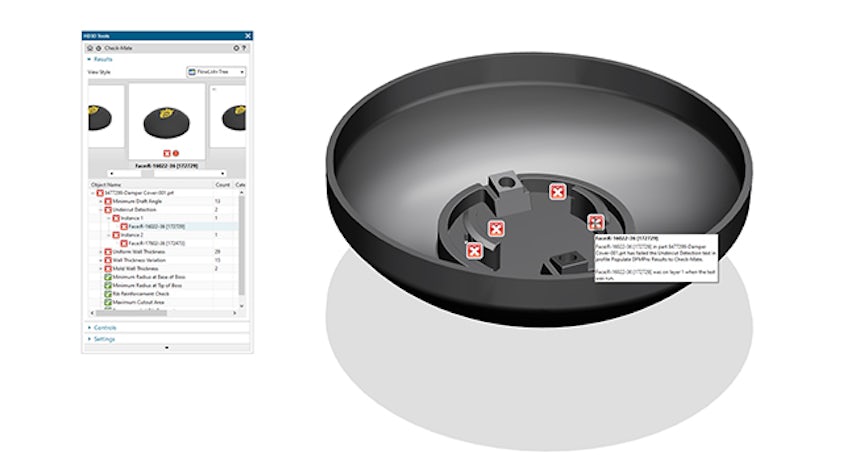

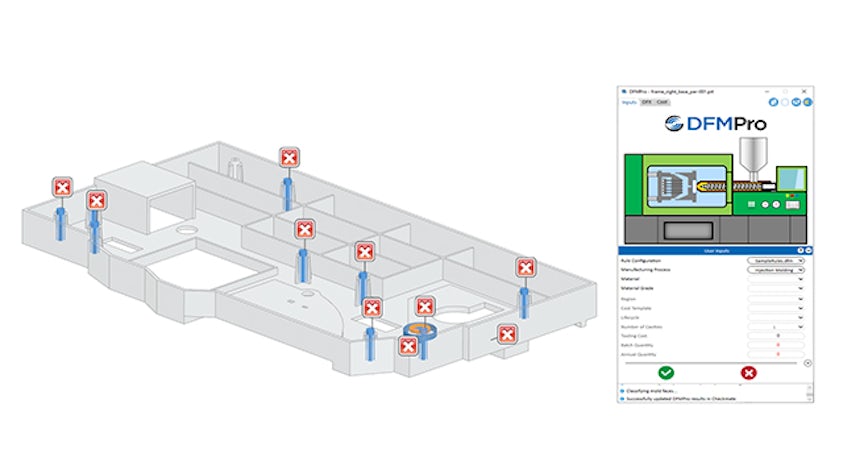

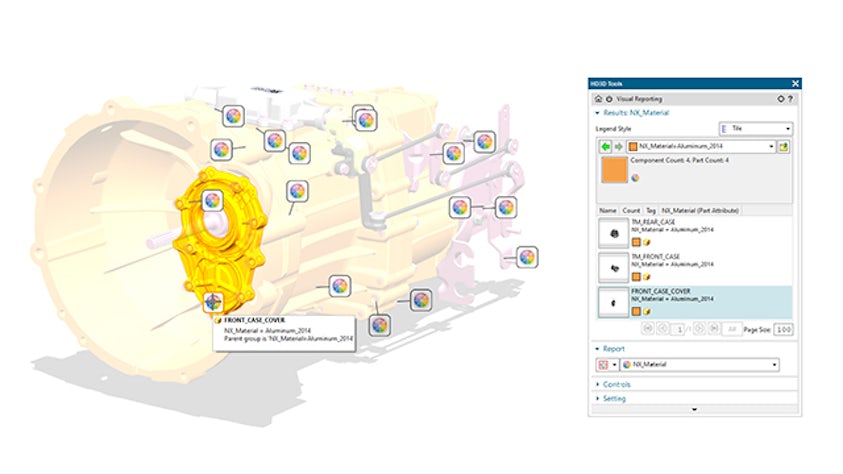

Dzięki automatyzacji sprawdzania projektu za pomocą narzędzia do wizualizacji NX Check-Mate sprawdzanie poprawności staje się ciągłym, proaktywnym procesem. Narzędzie uwzględnia rozbudowaną bibliotekę zawierającą setki standardowych kontroli przeprowadzanych w aplikacjach do modelowania, rysowania, przetwarzania informacji na temat produktów i ich wytwarzania (PMI), geometrii, trasowania, tworzenia połączeń spawanych i wielu innych. Za pomocą narzędzia do tworzenia treści można tworzyć niestandardowe funkcje sprawdzania poprawności. Sprawdzanie poprawności projektu jest ciągłym i automatycznym procesem, który generuje powiadomienia natychmiast, gdy projekty nie są zgodne z normami, najlepszymi praktykami lub wymaganiami funkcjonalnymi i technicznymi o znaczeniu krytycznym.