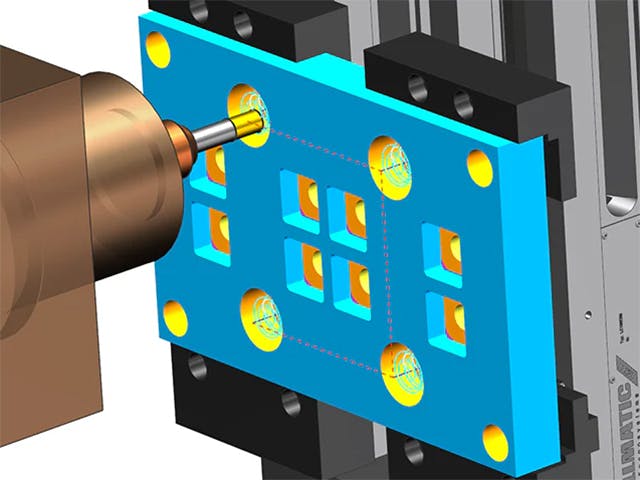

Twórz zaawansowane 5-osiowe operacje obróbki maszynowej

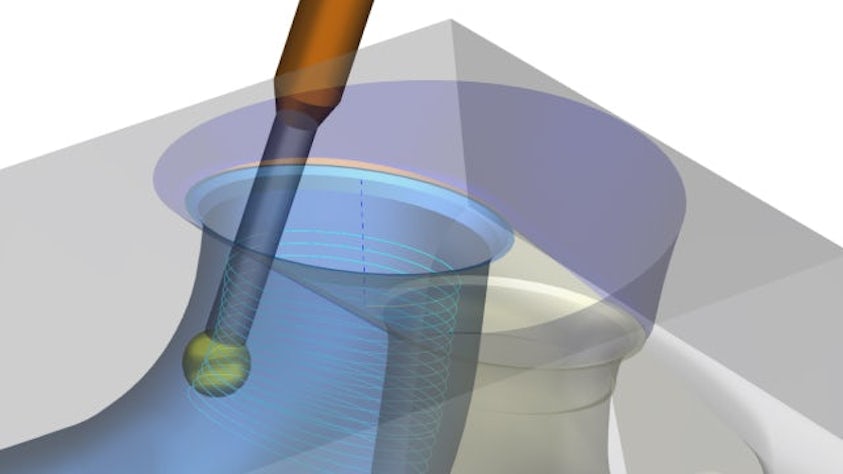

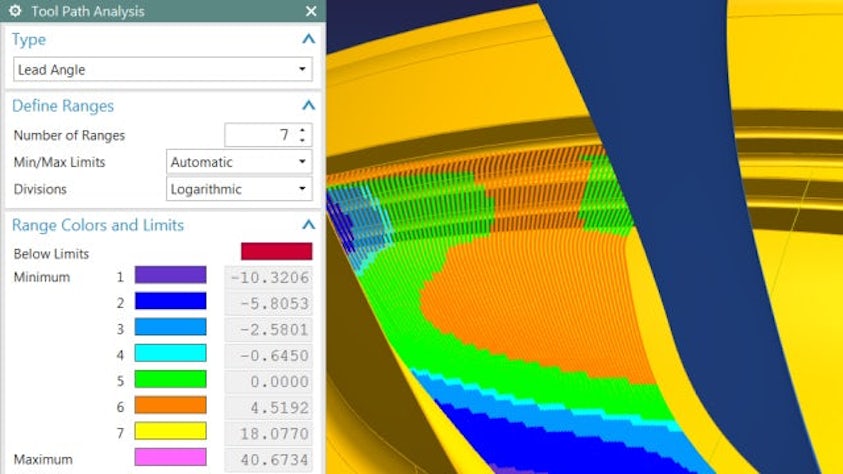

Wykorzystaj najnowsze wieloosiowe ścieżki narzędzi, które zapewniają precyzyjne sterowanie osią narzędzia i automatyczne unikanie kolizji.

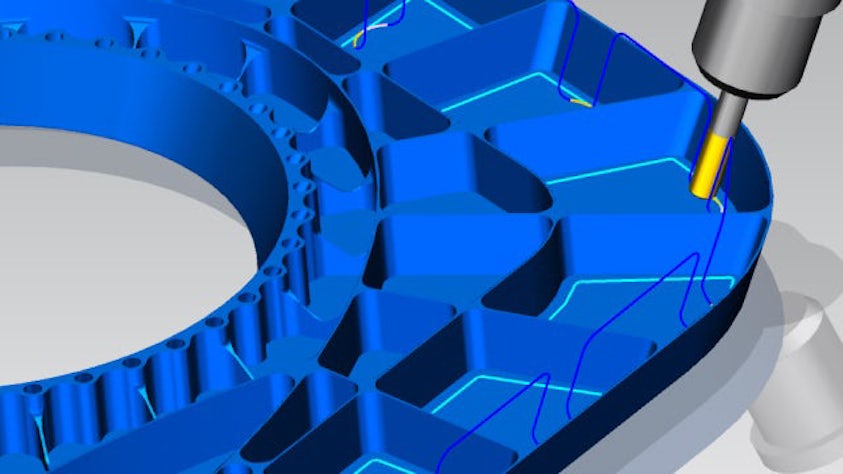

Frezowanie adaptacyjne, wieloosiowa strategia obróbki zgrubnej, może skrócić czas obróbki nawet o 60%. Metody gładkiego wykańczania mogą podążać za naturalnym kształtem części, pozwalając osiągnąć doskonałą jakość wykończenia.

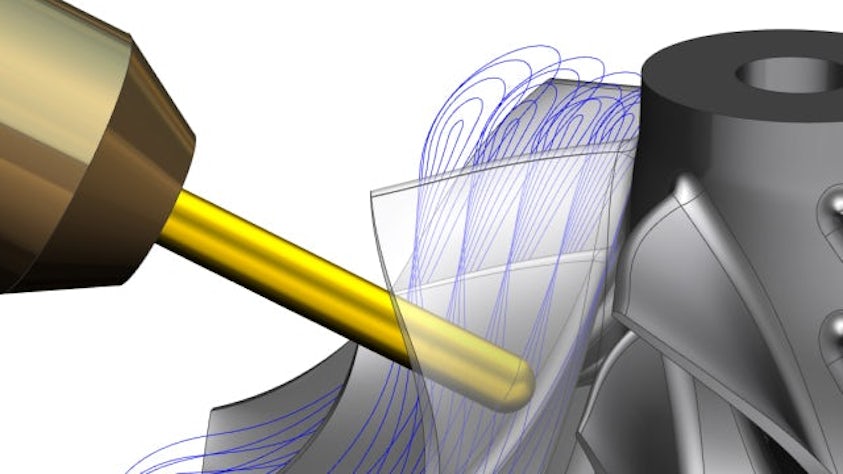

Narzędzia walcowe, które zapewniają lepszy kontakt narzędzia z obrabianym przedmiotem, pozwalają osiągnąć wyższą jakość części przy krótszych cyklach obróbki.