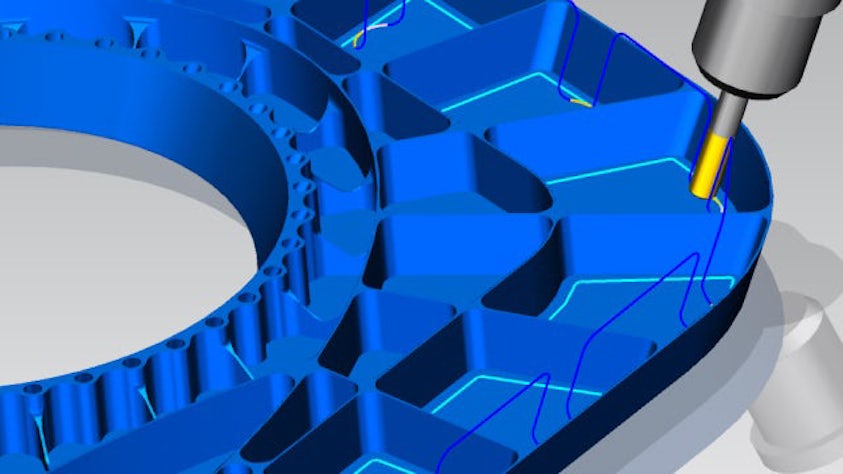

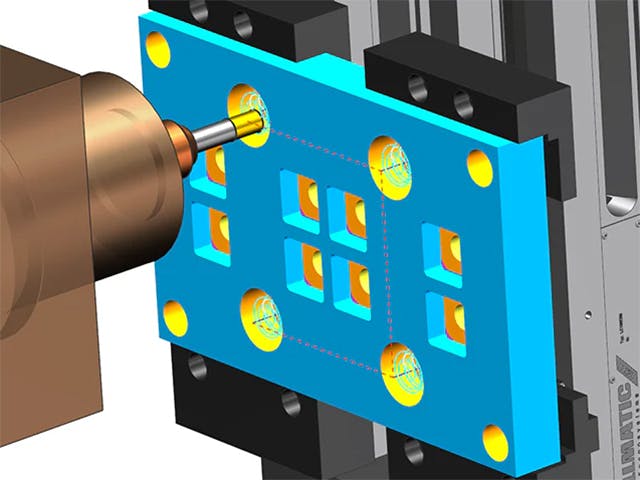

Create advanced 5-axis machining operations

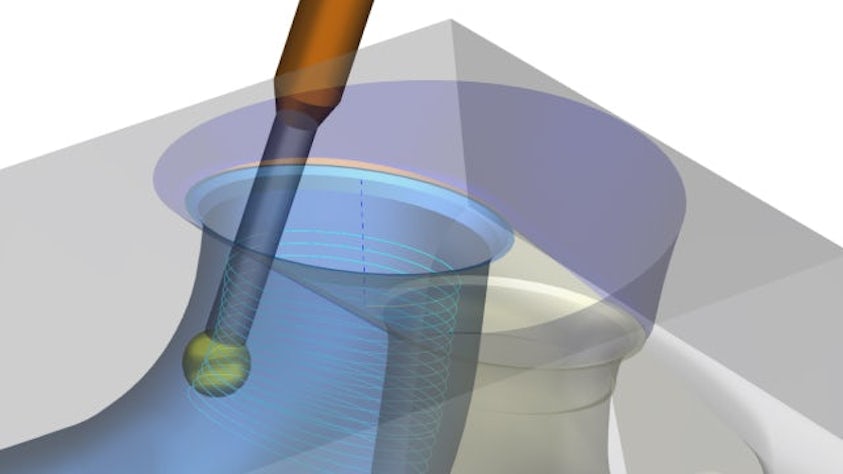

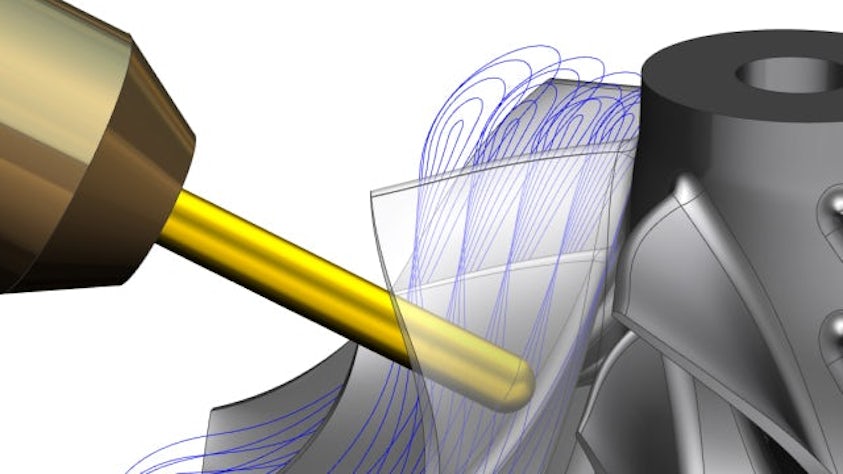

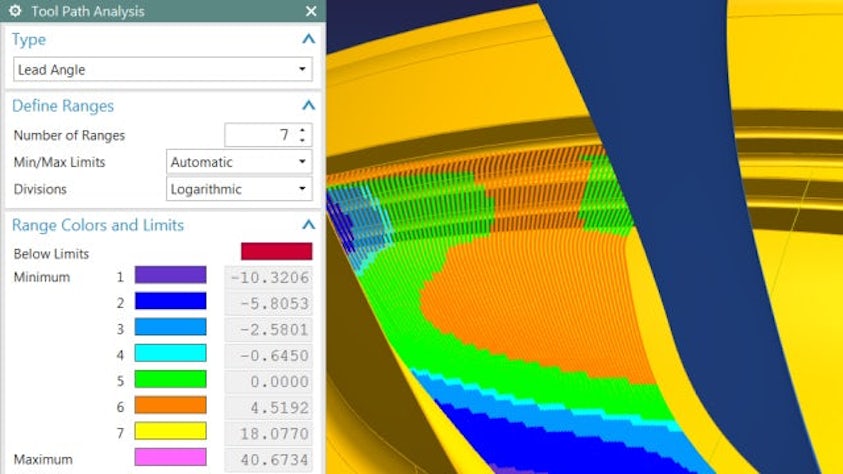

Leverage the latest multi-axis toolpaths that provide precise tool-axis control and automated collision avoidance.

Adaptive Milling, a multi-axis high-speed roughing strategy, can reduce machining time by up to 60%. The smooth finishing methods can follow the part's natural shape, achieving a superior finish.

Barrel tools, which allow larger tool engagement, enable higher part quality with shorter machining cycles.