Planar print technologies

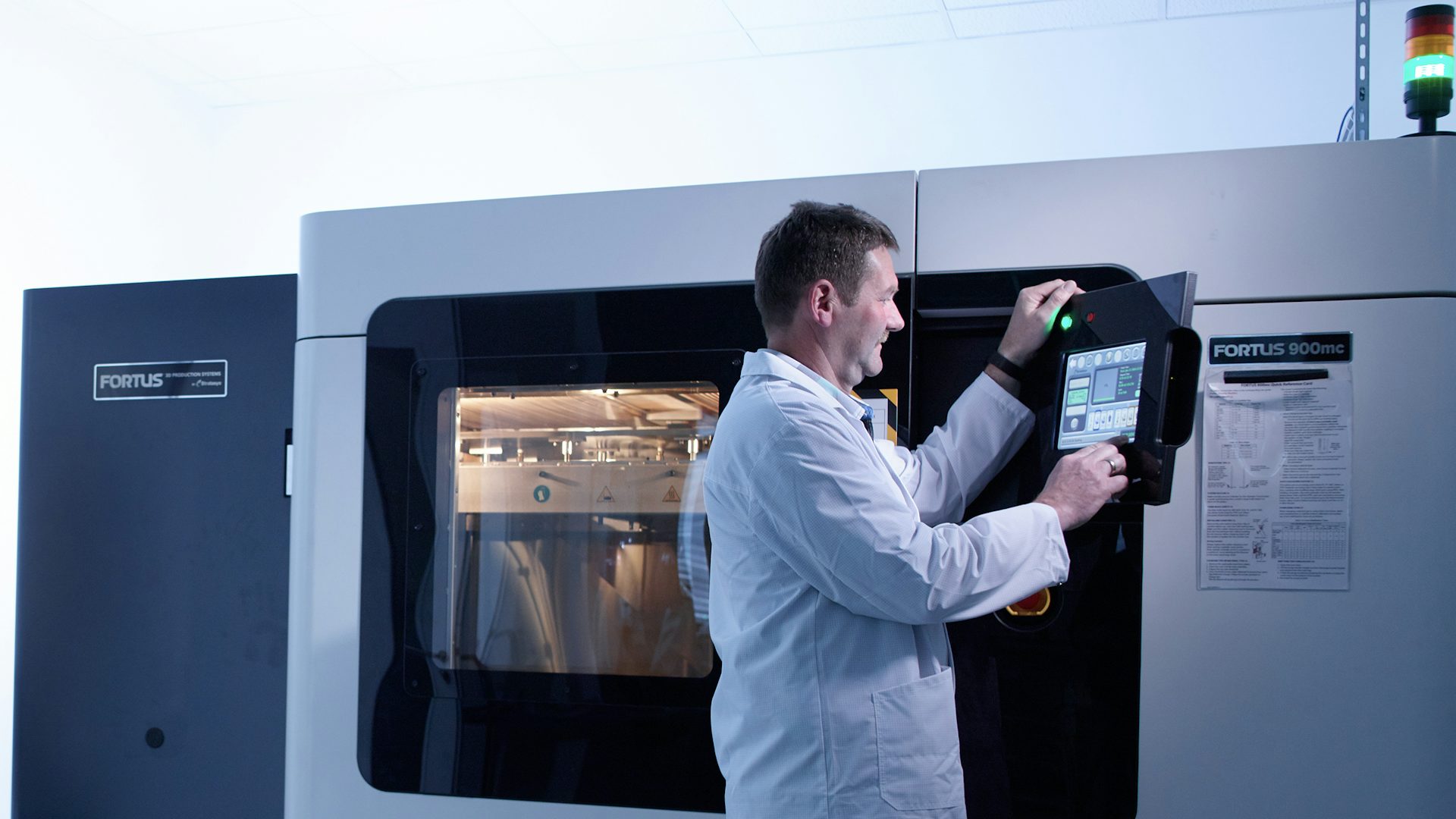

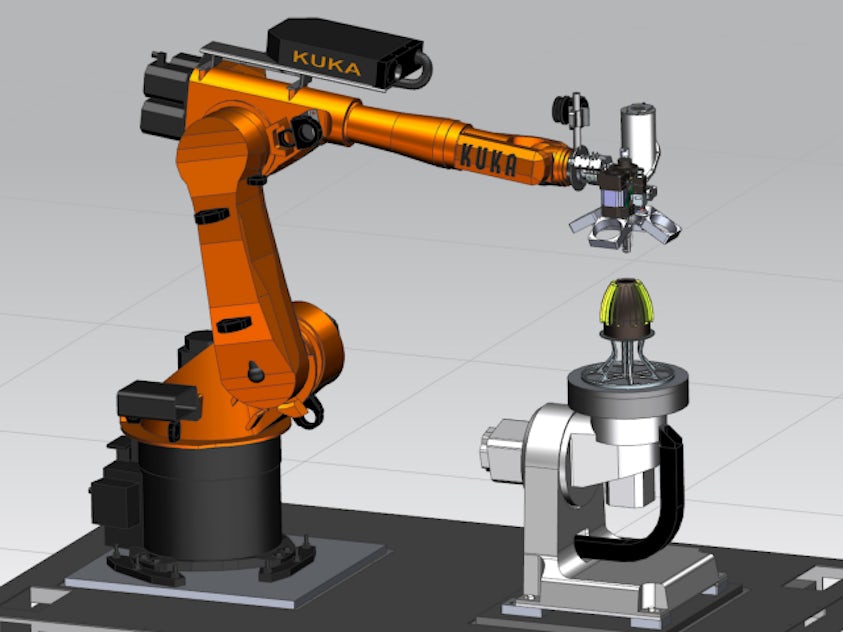

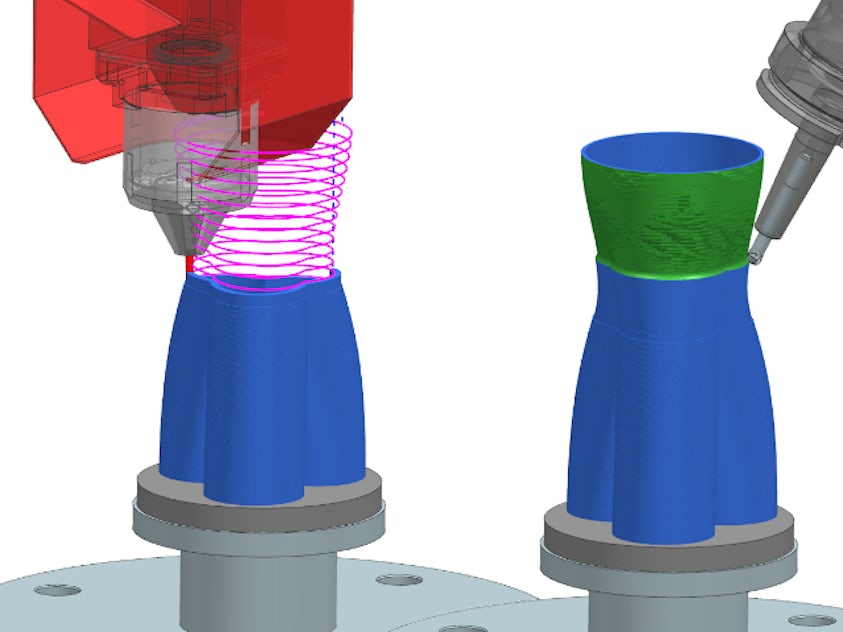

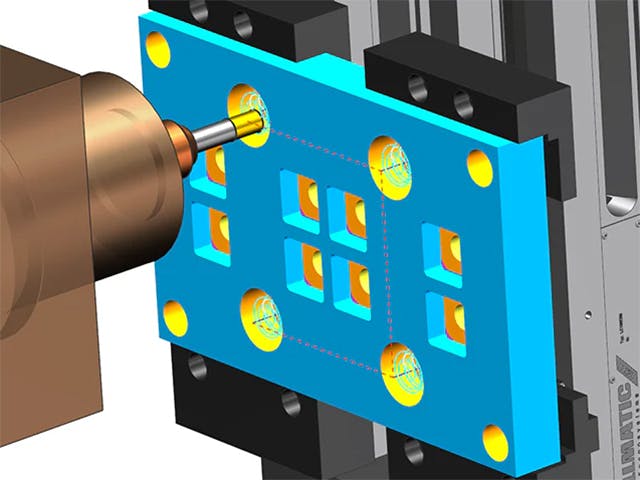

Utilize the most popular printing technologies for your manufacturing needs. The majority of 3D printers for printing both metal and plastic use a planar print process. We partner with the best industry-grade printer manufacturers to ensure that our NX additive manufacturing software works with their hardware. NX also supports hundreds of desktop printers through integration with Ultimaker’s Cura solution.