Driving multi-axis additive hardware takes special software. Normal planar 3D-print products cannot generate the complex 3D deposition paths required for multi-axis 3D printing. This is where the NX Additive Manufacturing (AM) Multi-Axis solution is key.

Create complex, 3D deposition paths

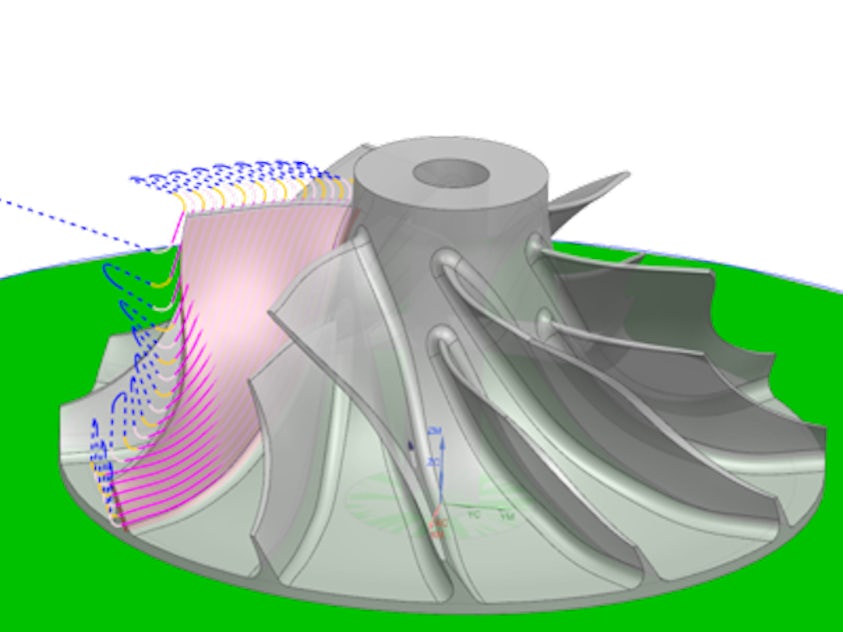

Drive complex deposition paths for multi-axis hardware using a combination of proven pre-programmed deposition paths, like helixes. Also use the software for advanced path planning for activities like cladding. These complex motion paths are almost impossible to generate accurately using other tools.

Access advanced AM path planning, validation and manufacturing preparation tools such as:

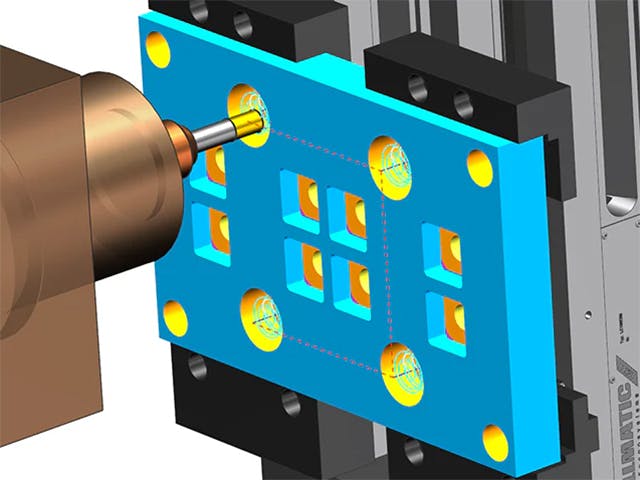

- A complete CAD tool set for feature decomposition, stage modeling and fixture design to setup jobs in your machine’s kinematic environment

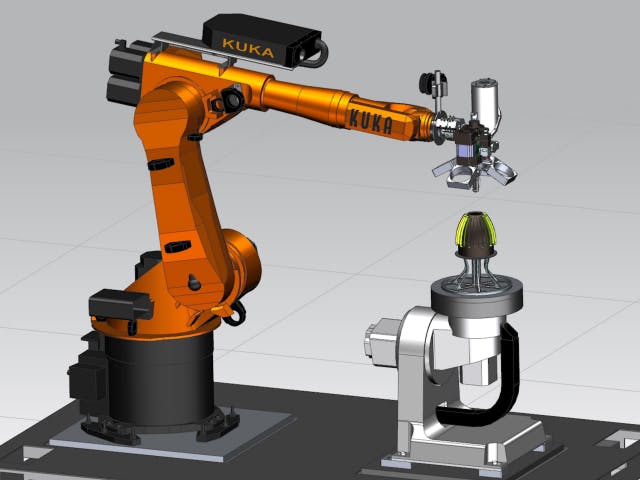

- Comprehensive simultaneous 5-axis AM path planning for robots and machine tools, supporting a wide range of tool path operations

- A powerful system to combine multi-axis deposition and subtractive manufacturing

operations in the same tool path setup - A simulation system to validate your multi-axis AM machining setup and analyze its performance via a production digital twin

- Highly productive, modular CNC automation systems controlling up to 93 axes in 30 machining channels