Accelerate your build setup for fixed-plane additive manufacturing (AM) equipment using our NX AM Fixed-Plane solutions. Regardless of the material type or parts you print, our solutions cover fixed-plane modalities, such as powder bed, jetting, Multi Jet Fusion (MJF), fused filament fabrication (FFF) and more.

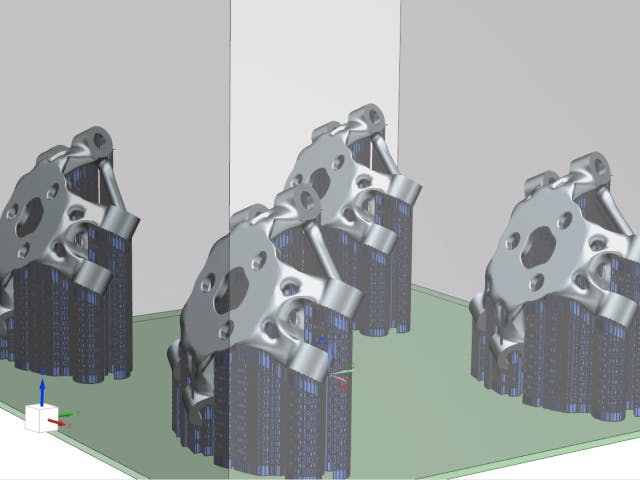

Import parts and setup your build tray

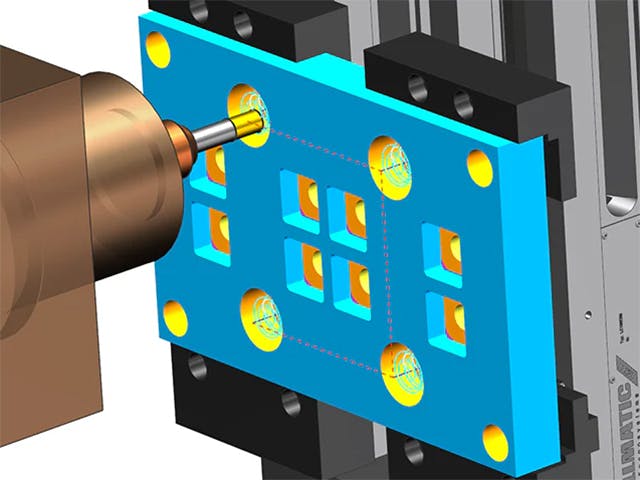

Use the NX AM Fixed-Plane tools for build tray setup, basic support geometry (block, line and point) creation, and the build processor framework, which supports build processors for various types of additive manufacturing equipment. The solution also provides 3MF and STL file-based export of the build tray. Access these products as part of a bundle that includes NX solid modeling and drafting, feature modeling, basic freeform modeling, assembly modeling and user-defined features.

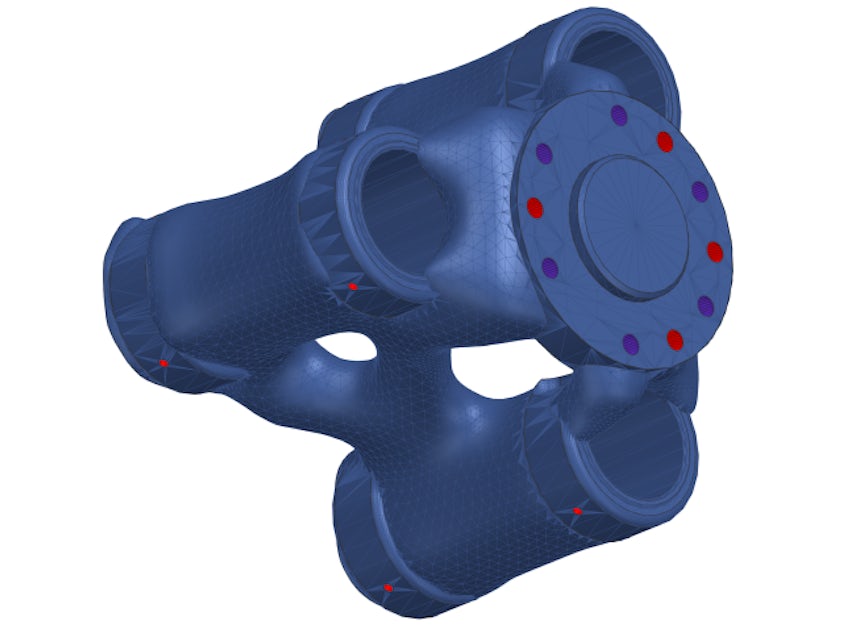

Edit and fix models before printing

Use the integrated NX CAD tools, like synchronous modeling, to prepare 3D models for printing and to edit part geometry to accommodate design change requests. The assembly capabilities enable you to model complete multi-part assemblies you can print.

Maximize your productivity with advanced capabilities

Gain more functionality when you add in advanced support geometry types, such as gusset, contour, web, cone, volume and user-defined supports. Create a bundle with access to best-in-class facet body editing tools for working directly with mesh bodies, such as imported STL or 3MF files.

NX AM Fixed-Plane solutions provide advanced additive manufacturing build setup tools, including:

NX AM Fixed-Plane Basic tools:

- Effortless drag-and-drop part placement and orientation

- Automatic and manual support structure creation

- Automated print mark generation

- Generation of print code for direct printing to supported hardware

- Slice viewer for supported printer types

NX AM Fixed-Plane Advanced tools:

- All capabilities present in NX AM Fixed-Plane Basic solutions

- Gusset, contour, web, cone, volume, and user-defined support structure creation

- 2D and 3D nesting of parts in the build tray

Note: For a current list of printers with direct print support, please talk to your salesperson.