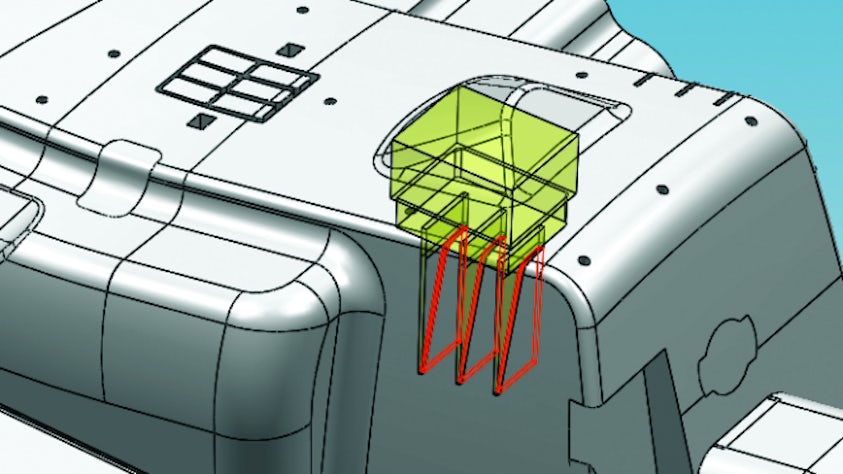

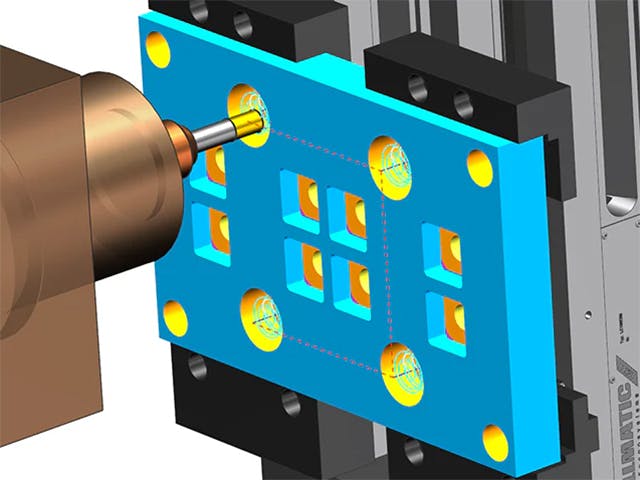

Identify manufacturing geometry automatically

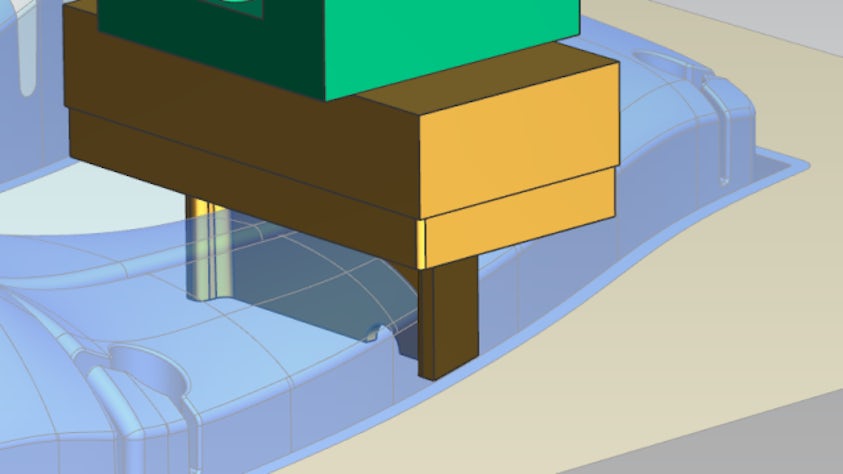

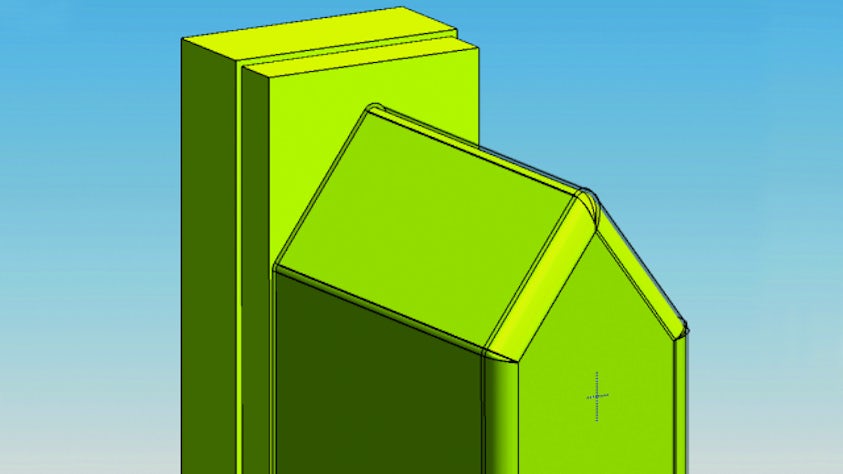

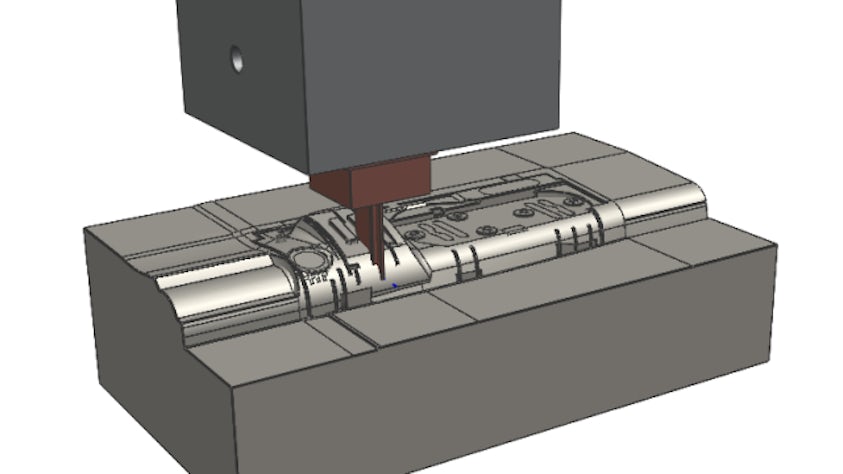

Automate how you define the manufacturing processes for the core and cavity.

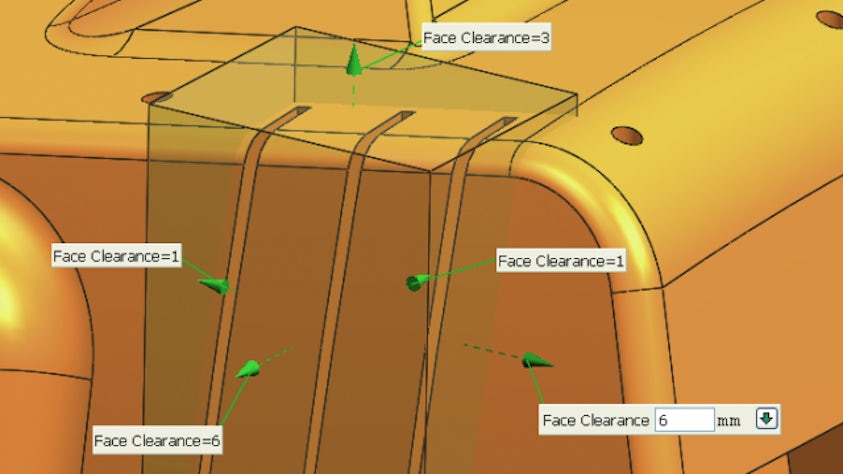

You can automatically search, recognize, group and color faces that you want to burn and rough through EDM, wire EDM (WEDM), milling and grinding.