Opcenter

Opcenter Scheduling SMT

Opcenter Advanced Scheduling delivers decision-making for overtime, order prioritization, production batches, due date negotiation and order processing.

Change country

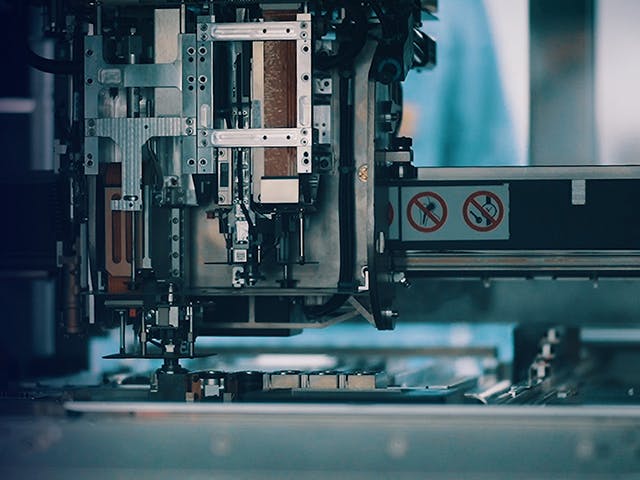

Opcenter Scheduling SMT

Create realistic production schedules based on actual factory capacity. React to changes in the manufacturing environment with a real-time scheduling solution.

Intelligent product grouping

Generate optimal product groups. Take into consideration machine capacity, feeder and material availability, and work-order priority. Control optimization parameters, such as due dates, production time and change-overs. Compare different scenarios. You can then choose the schedule that best fits your needs.

Performance tracking

React to changes quickly using actual versus scheduled performance tracking. Detect potential bottlenecks in time to prevent them. Modify shift schedules or add additional lines to see how such changes affect your ability to meet deadlines. Update schedules and export them for added visibility and monitoring.

Production plan simulation

Easily make on-the-fly optimizations based on different scenarios to support the planner’s decision-making process. Additional what-if scenarios can be made based on scheduled material arrival and material location data. Then generate realistic SMT production schedules based on actual factory capacity and constraints.

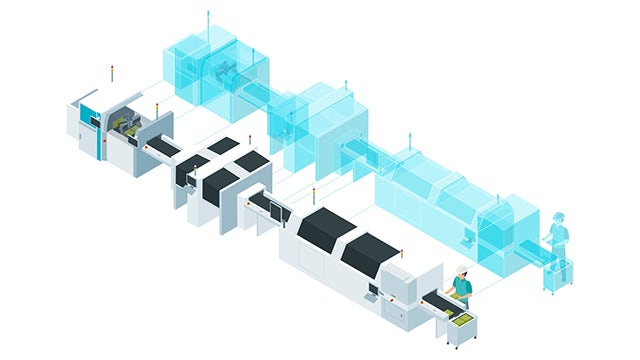

Built-in connectivity

Opcenter Scheduling SMT offers built-in connectivity to a range of SMT production solutions and to Valor Process Preparation software. This gets you started quickly and allows simple daily workflows, and eliminates manual, error-prone processes.

Seamless SAP integration

Opcenter Scheduling SMT enables you to save the time and effort typically required to coordinate between SAP and your scheduling process. Extract work orders, required delivery dates, release data and material stock levels from SAP ERP simply and easily.

System requirements

Seventh generation Intel Core i5 processor

16GB random access memory (RAM)

Double the amount of RAM for virtual memory (paging file size)

50GB disk space

Windows 10