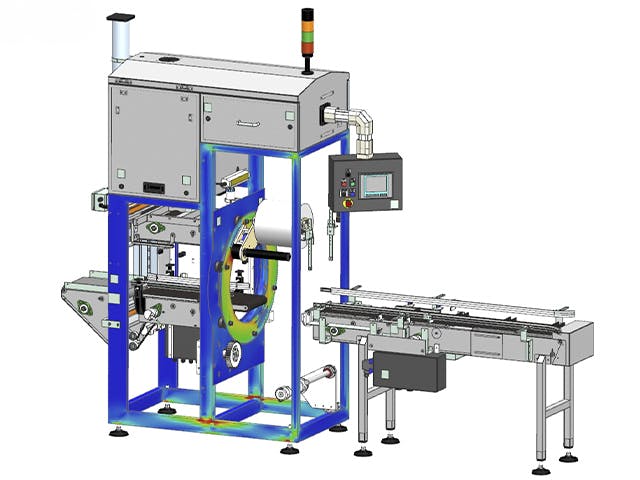

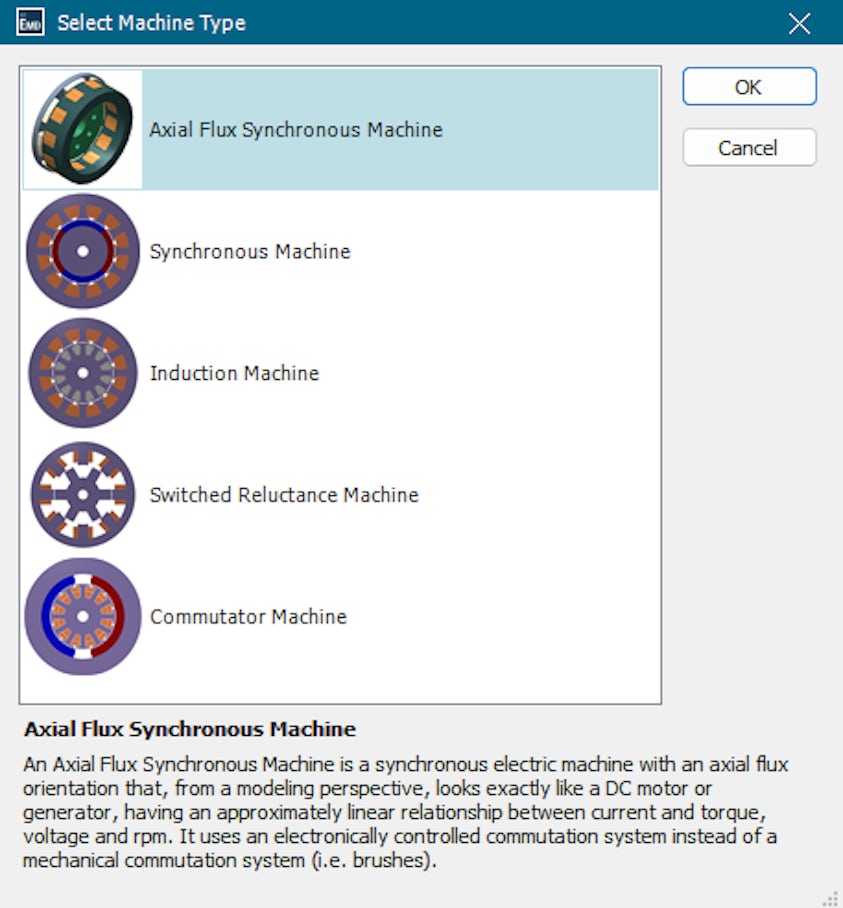

Simcenter electromagnetic (EMAG) simulation solutions include dedicated electric generator and electric motor design software for the complete design cycle. Simcenter simulation offering ranges from fast analytical equivalent circuits and accurate automated finite element analysis (FEA) simulations to detailed multi-physics simulations for detailed design validation. You can trade speed for detail to fit the development stage you are currently working on, then modify your selection when you move on to the next development stage.

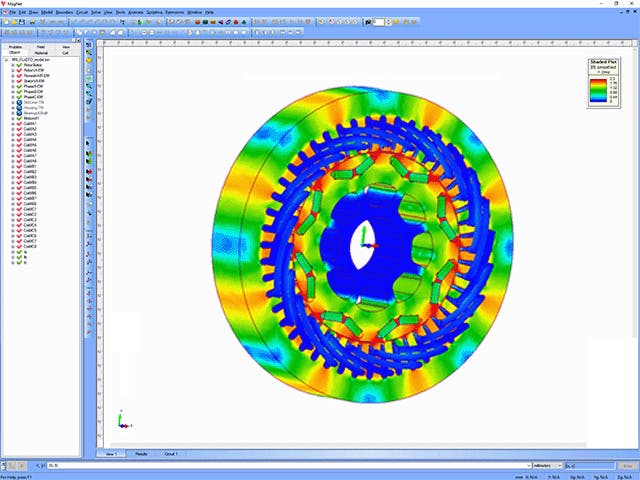

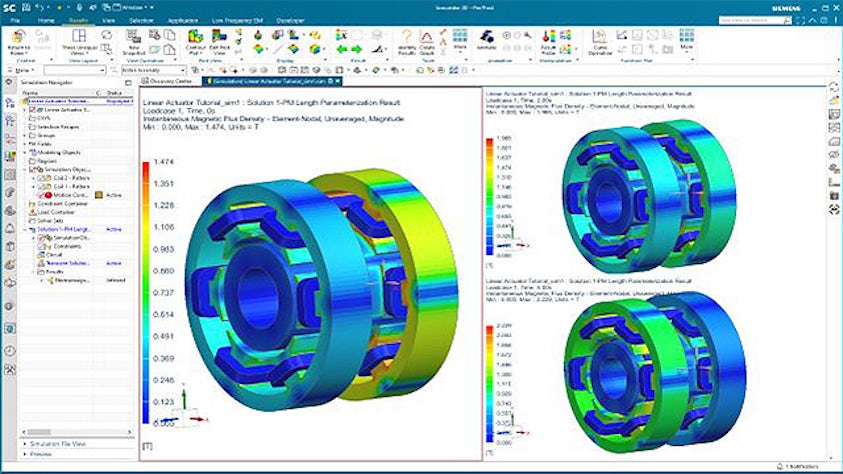

Start with the template-based interface that includes all common motor types. Customize your rotors and stators geometries using the parameterized templates. This enables you to create an initial design in minutes. Rapidly test, tune, and retest the EMAG performance of this design with the analytical solver. Ensuring you find potential EMAG or thermal failures as early as possible with early multi-physics analysis. Then, render your design into an FEA model to complete a detailed EMAGs, or multi-physics analysis, including full noise, vibration and harshness (NVH) studies.

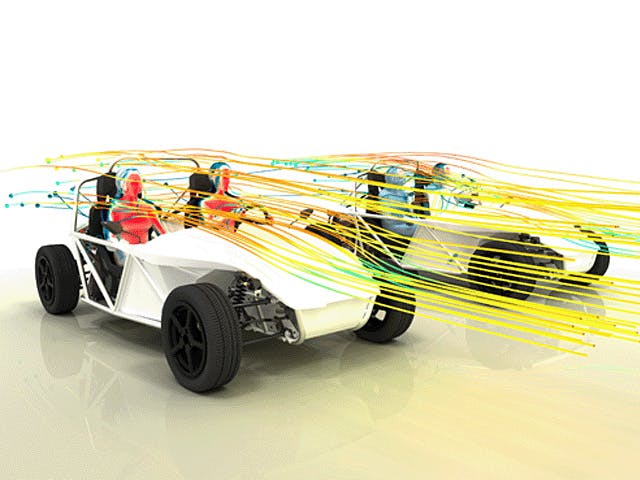

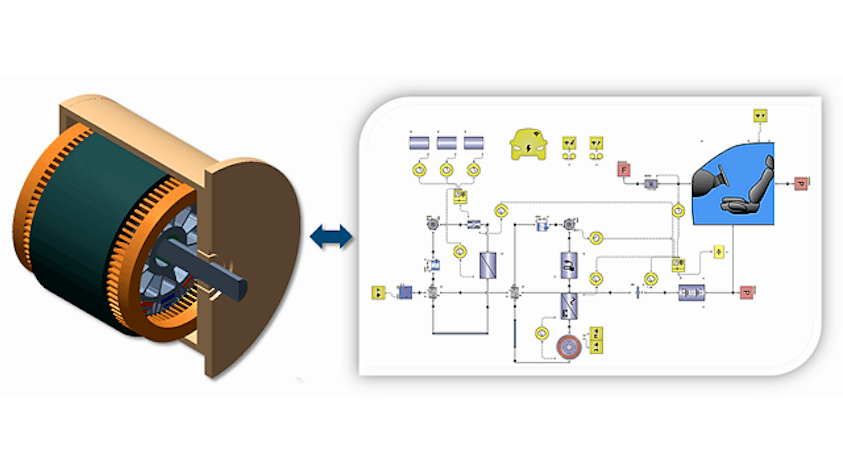

With native connectivity from Simcenter E-Machine Design to Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and Simcenter HEEDS you can test your motor with its required transmission or as part of its full system and optimize the design as part of the system, respectively.

Accelerate, innovate, and optimize your electric machine design process

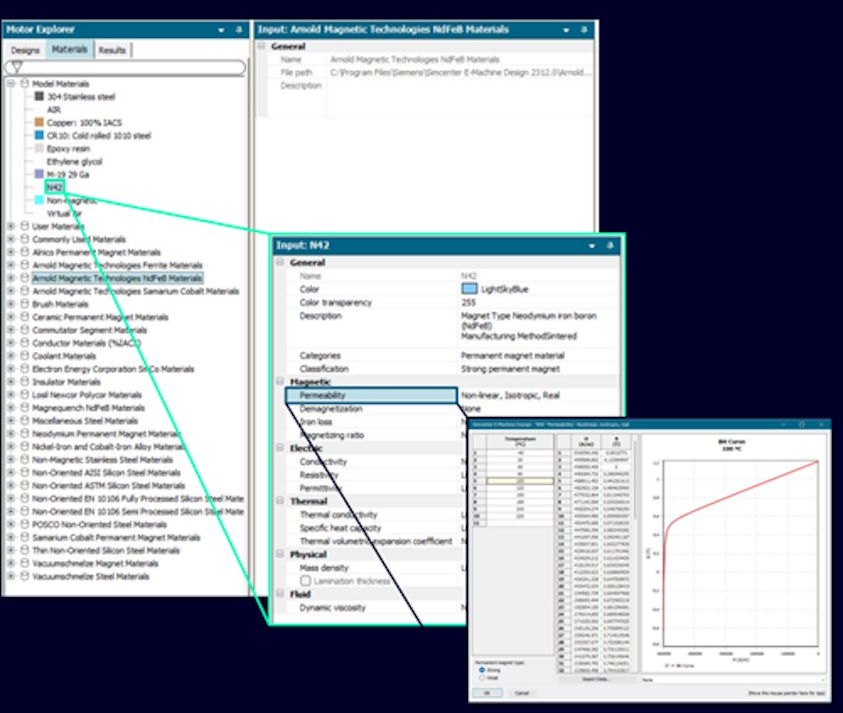

Simcenter E-Machine Design is a new product built upon the shoulders of giants as it takes the best of Simcenter SPEED, Simcenter Motorsolve and Simcenter MAGNET for replicating electric machine experiments.