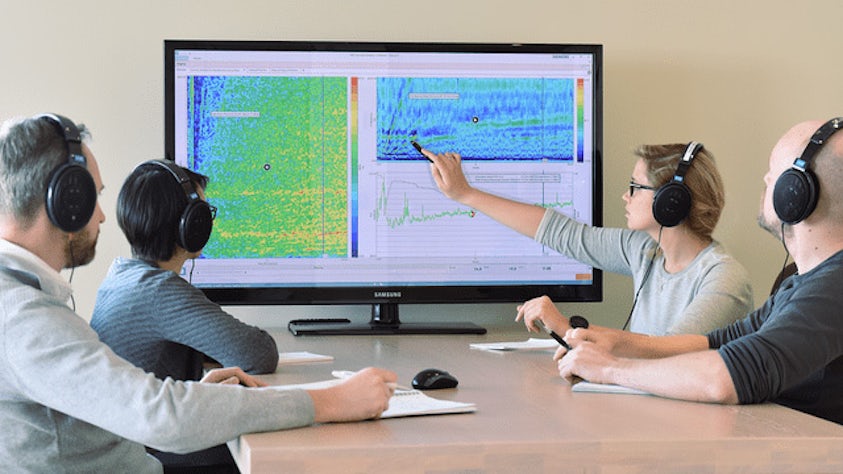

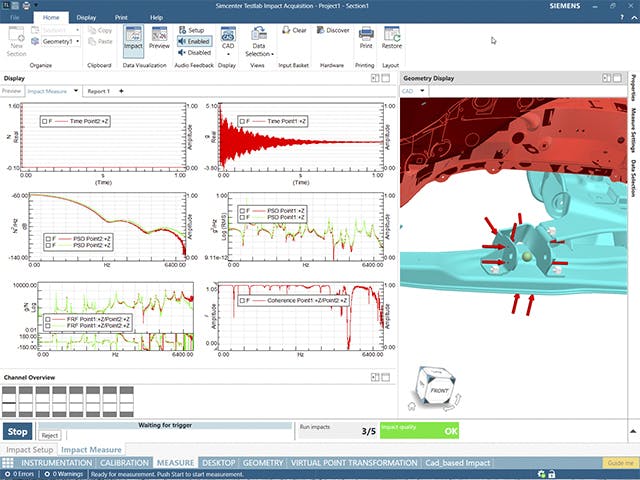

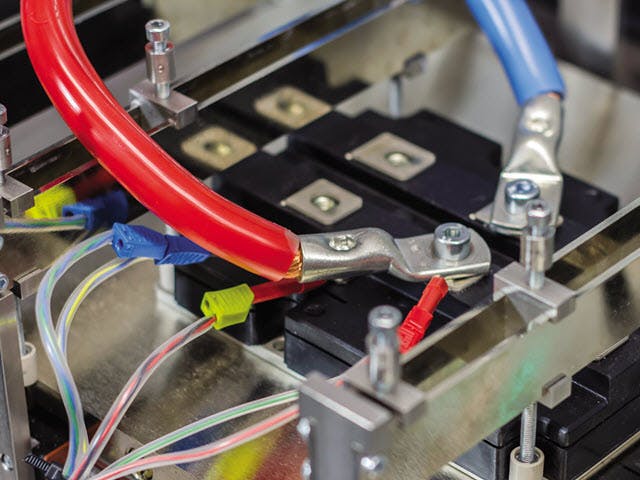

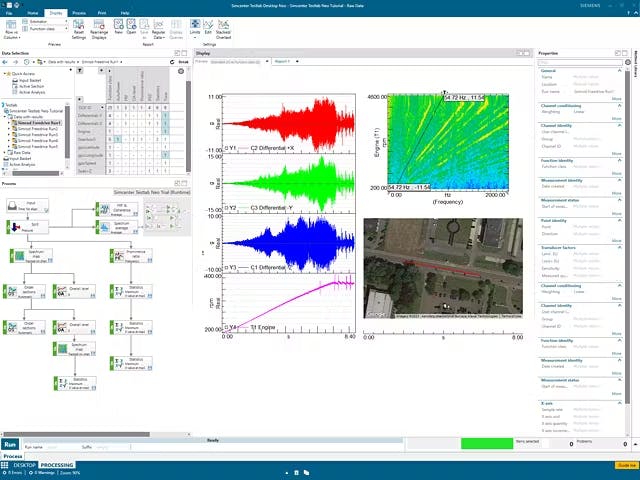

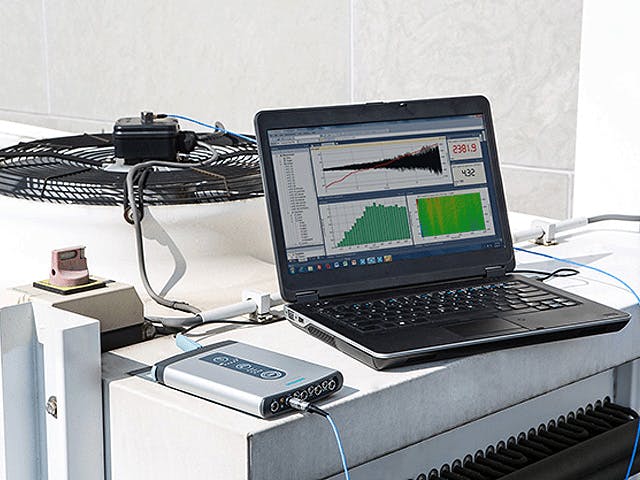

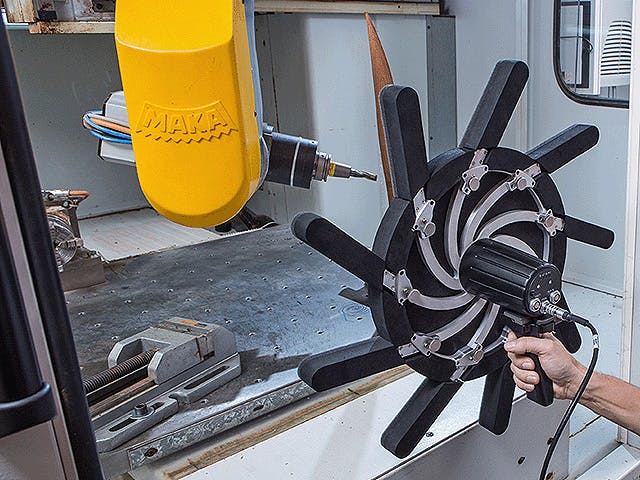

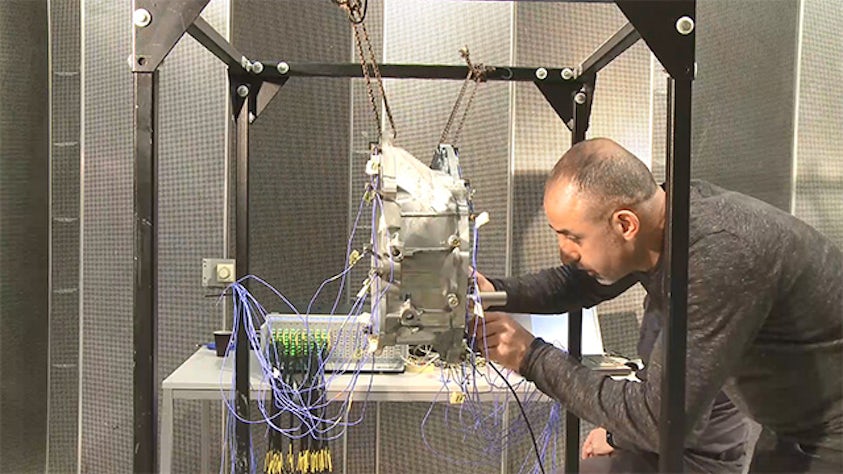

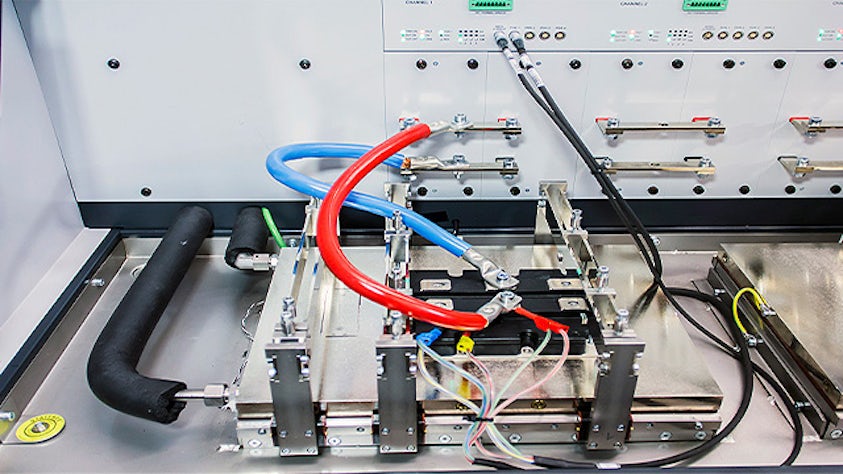

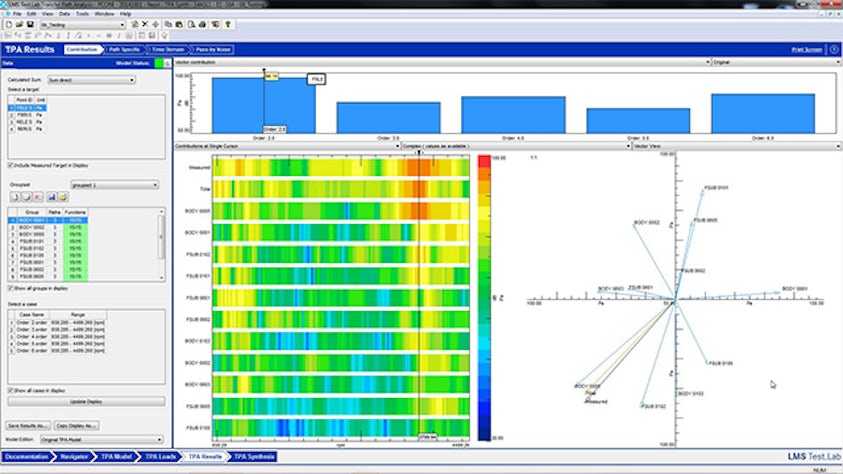

Covering the broadest range of industry applications and engineering tasks while conforming to the latest international standards, our acoustic testing solutions adjust to your project’s requirements. Design innovative products with a compelling acoustic signature, relying on the expertise nested in Simcenter Testlab.