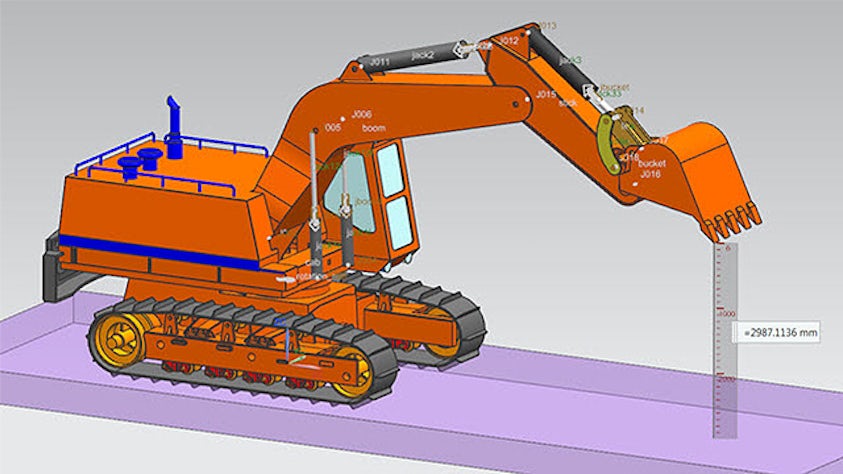

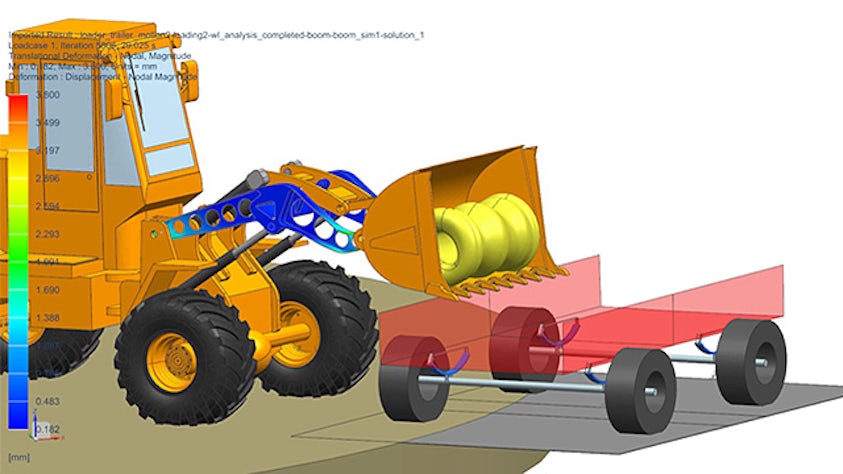

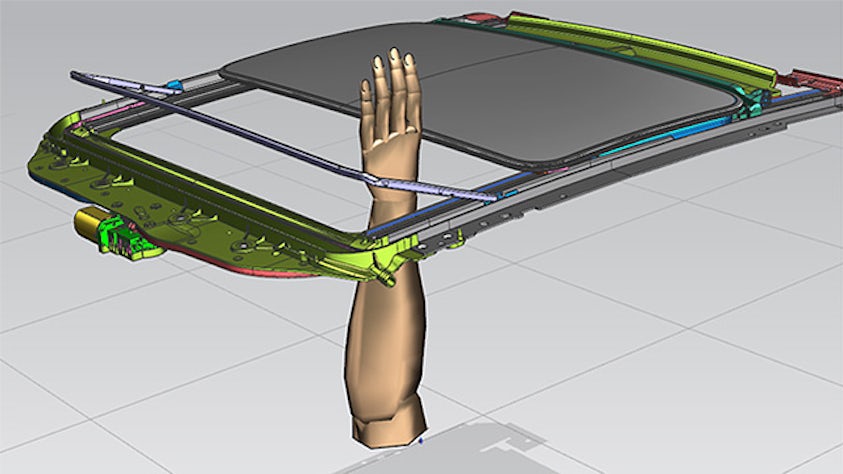

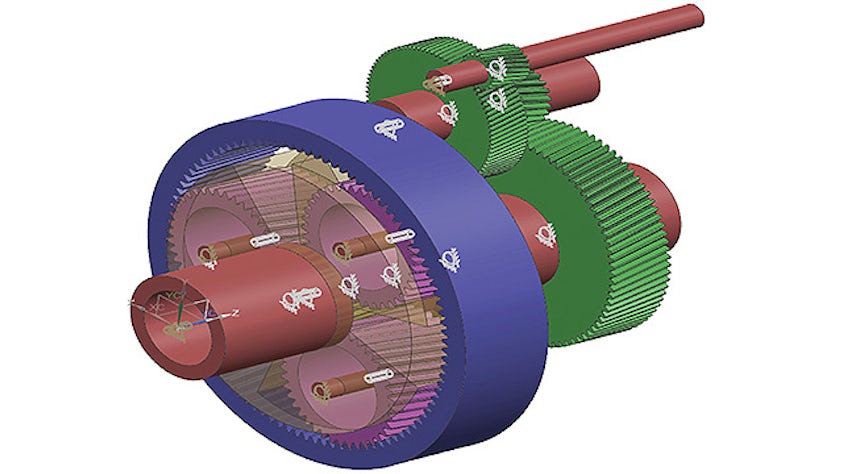

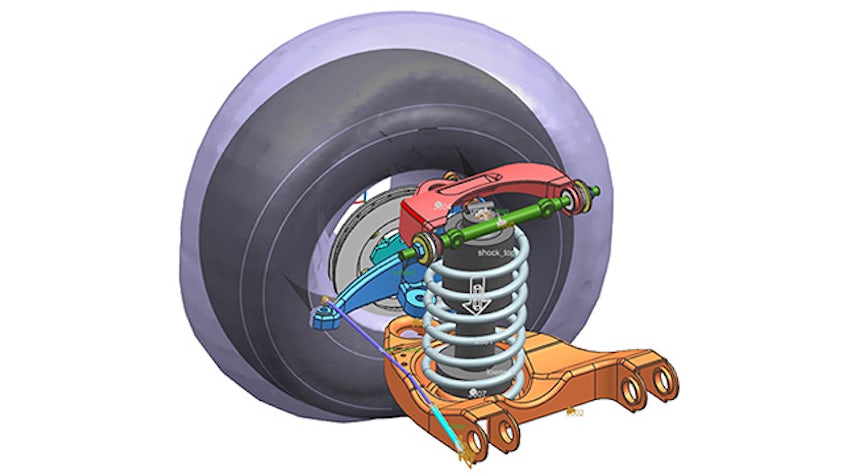

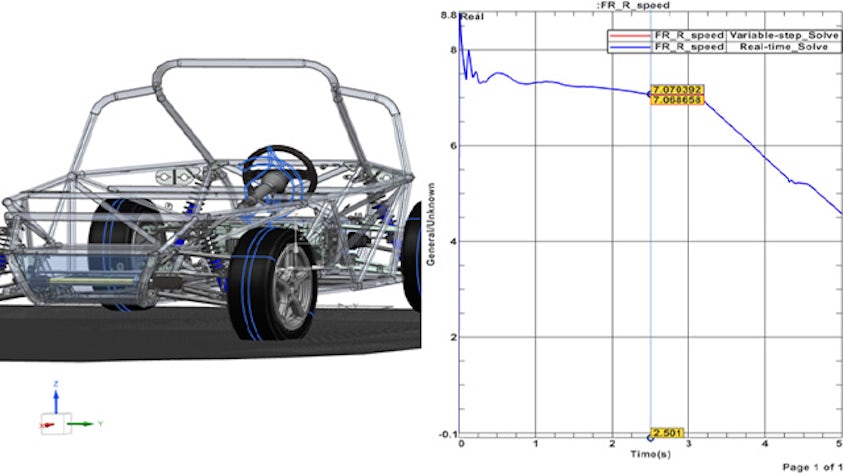

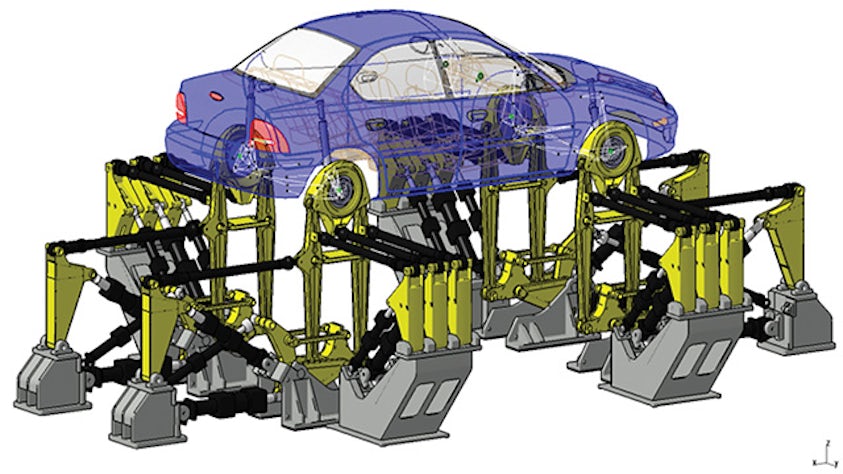

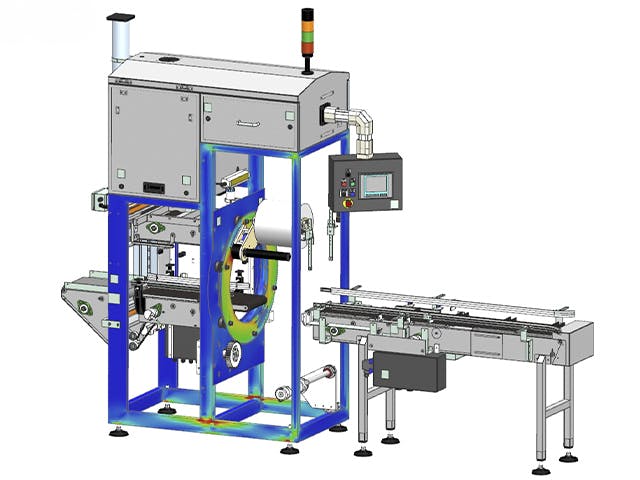

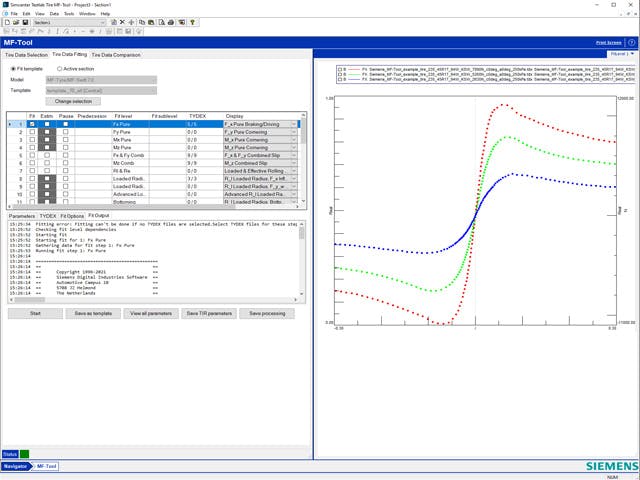

Understanding engineering performance is challenging for intricate mechanical systems, like wing flaps or landing gears, sliding sunroofs or suspensions, or photocopiers and other mechanisms. Motion simulation uses multibody dynamics to calculate the reaction forces, torques, velocities, acceleration and more for mechanical systems. You can directly convert CAD geometry and assembly constraints into an accurate motion model, or create your own multibody model from scratch. The embedded motion solver and robust post-processing capabilities enable you to study a broad range of mechanism behaviors.

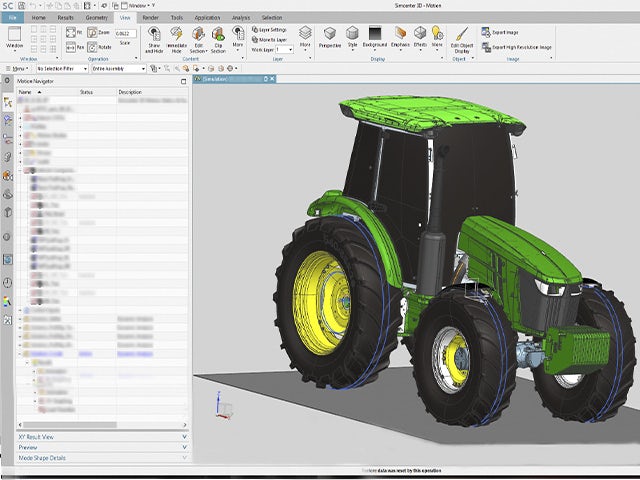

Simcenter motion simulation software helps engineers understand and predict the functional behavior of mechanisms. It delivers a complete set of capabilities to support all aspects of advanced dynamic, static and kinematics motion simulation.

Simcenter 3D for motion simulation solution guide

The early use of motion simulation is key to increase design confidence and reduce risks.