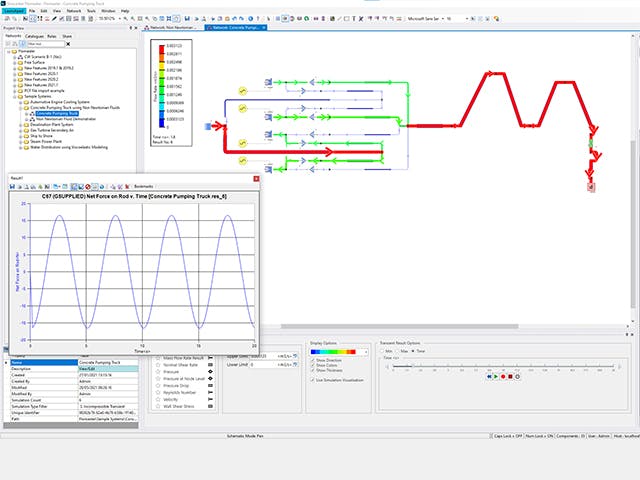

Maximize the return on investment leveraging the digital twin of your thermo-fluid systems throughout its entire lifecycle. You can reuse the model built in the engineering phase as an executable digital twin to support procurement, commissioning and operations.

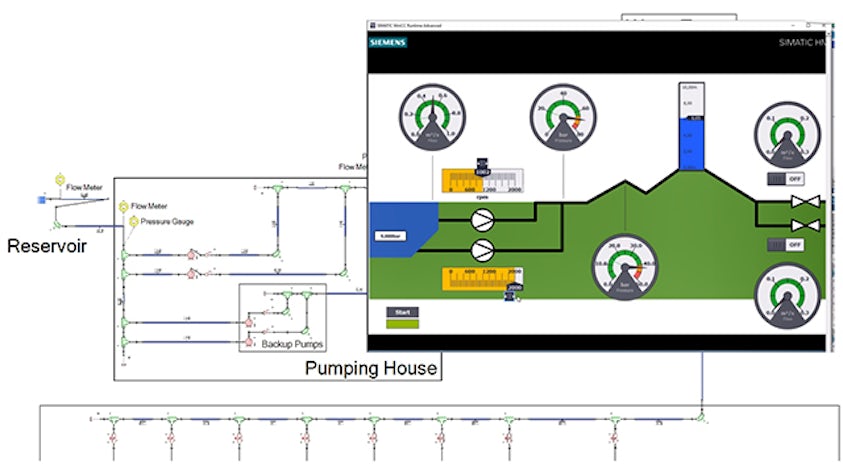

Perform a cost-based design optimization to minimize both capital and operational expenditures and support procurement operations. Connect the digital twin of your thermo-fluid system to a virtual programmable logic controller (PLC) to verify their interactions in a safe virtual environment before the system is built. Finally, connecting the executable digital twin to the real system sensors and controllers via industrial Internet of Things (IoT), you can augment the information available to the operators to maximize efficiency and safety of system operations.

Reducing costs while improving the safety of all complex thermo-fluid systems

Fluid systems are used for a variety of tasks including cooling and heating, product transport, energy production, and overall plant safety. It is critical to optimize their performance and safety.