Design better factories and lines faster

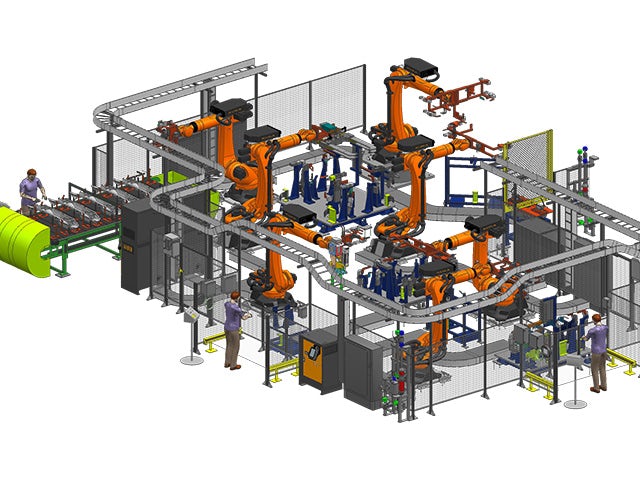

Enable accurate impact analysis and efficient change management for factory layouts, line layouts and equipment designs directly linked to manufacturing process plans.

Create required fixtures, tools and equipment using a classified library of parametric resources integrated with manufacturing planning and factory design to achieve a better production layout faster.

Validate and optimize factory line designs

Use simulation software directly within the line planning environment to fully validate and optimize your factory designs and production layouts.

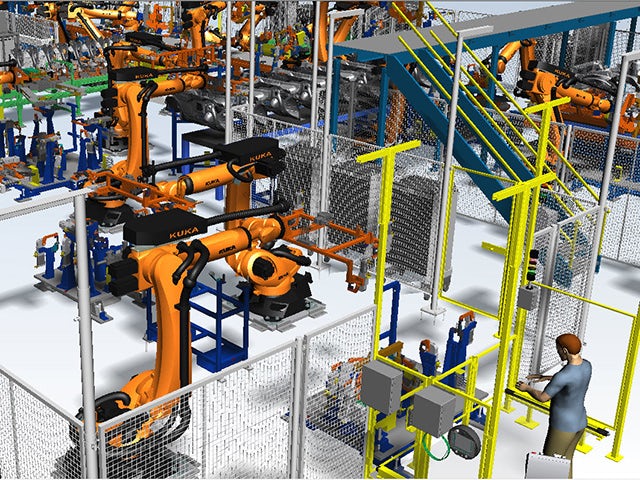

Simulate operations including robots, tools, material handling equipment and people at the detailed station level, line level or factory level to optimize automation and equipment locations, ergonomic requirements, material delivery strategies and production rates.

Commission factory production lines virtually

Use hardware-in-the-loop (HiL) and software-in-the-loop (SiL) simulation technology to virtually commission assembly lines and equipment during installation and prior to the start of production.

Test control logic and the interfaces between mechanical and electrical engineering using the real control system and digital twin to validate the operation of material handling systems and production layouts virtually.

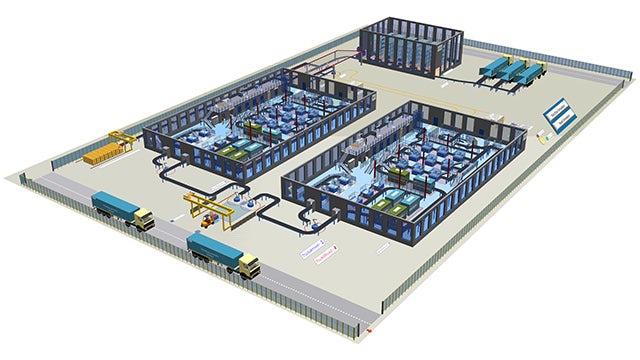

Navigate factories anywhere at anytime

Access cloud-based digital twins of your production facilities presented in their geographical context. Navigate the facility in a simple and familiar way with intuitive access to information from any IT system.

Facilitate a virtual tour of your factories using rich visualization tools and techniques with the ability to get relevant information and alternate viewpoints by simply clicking on visual tags.

Ford Motor Company

Automaker shows how streamlined assembly line design helps to connect disparate systems and drive cost efficiency in manufacturing.

Ford automates factory layout design

Company: Ford Motor Company

Industry: Automotive and transportation

Location: United Kingdom

Siemens Software: NX Line Designer, Teamcenter Manufacturing

.png?auto=format,compress&w=640&h=360&q=60&fit=crop)