Analyze workcells for operator comfort and safety

Scale virtual humans to match worker populations and test human-centered designs for multiple factors, including injury risk, user comfort, reachability, line of sight, energy expenditure and fatigue limits.

Enable the integration of human factors and ergonomics into the planning, design and validation stages of your product lifecycle to generate significant cost and time savings.

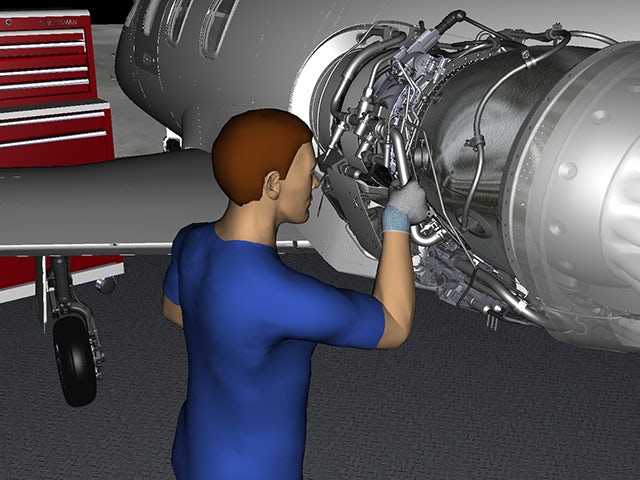

Design and build products that are easily maintained

Address maintainability during product design and manufacturing planning using human simulation to improve service times, identify and correct ergonomics and safety hazards, and minimize lifecycle maintenance costs.

Evaluate available space for part replacement, identify special tooling requirements for maintenance and create training material without the need for physical equipment.

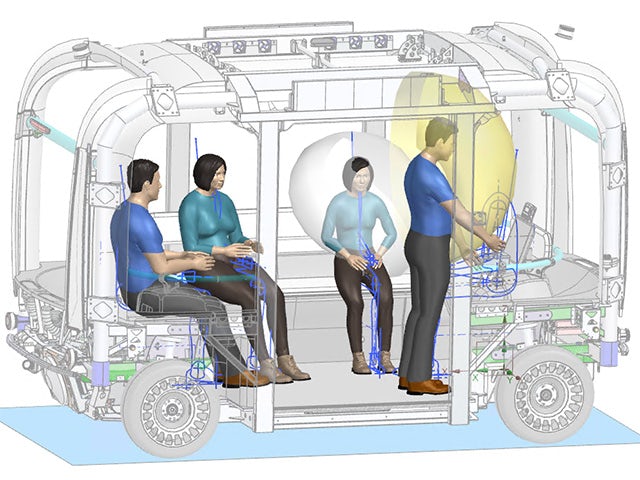

Optimize vehicle occupant performance and comfort

Analyze concept vehicles for human factors and ergonomics to design better interior spaces for automobiles, buses, trucks, airplanes and construction equipment.

Use human modeling and analytical tools to design vehicle interiors for optimal occupant performance and comfort, while reducing the need for costly physical prototypes and time consuming design revision cycles.

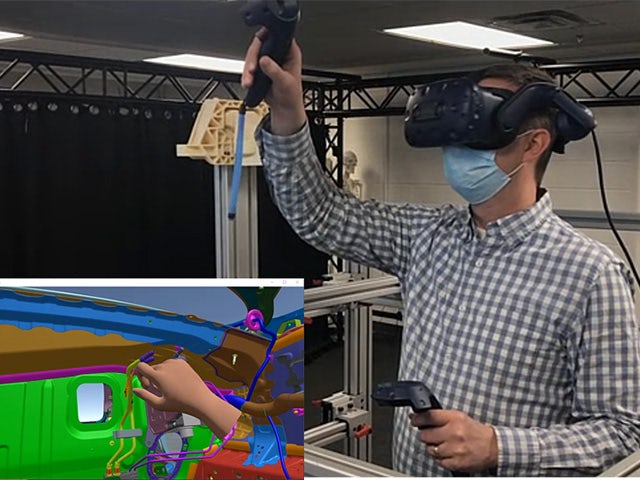

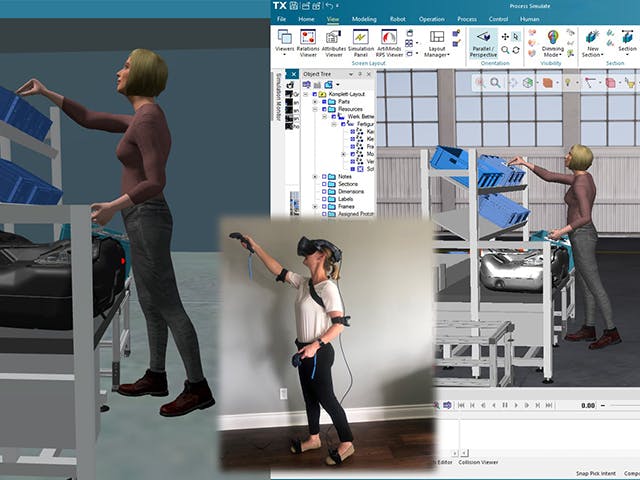

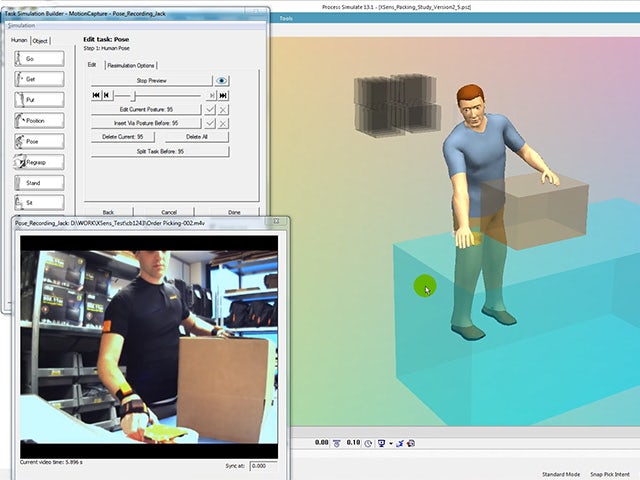

Improve ergonomics with motion capture

Generate accurate motion in an instant and create real-time visualization of human activities.

Improve the review of manufacturing processes and product designs by coupling motion capture with human modeling. Enable direct interaction with virtual environments to quickly develop human-centered designs and procedures.

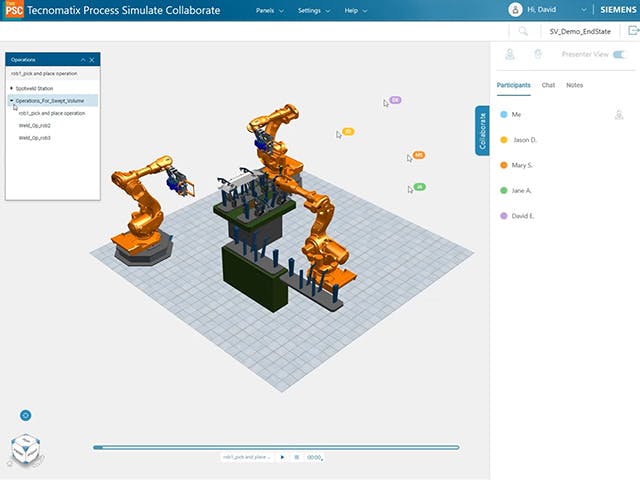

Use virtual reality for immersive design

Connect with colleagues in a virtual reality (VR) environment for collaborative reviews to experience human-centered designs firsthand, no matter where you are in the world.

Perform and evaluate manual assembly sequences while immersed in VR to dynamically identify and track ergonomics issues. Study clearance, reach and postural demands using human simulation to record and evaluate human motions.

General Motors

General Motors uses virtual reality and human simulation together to accelerate early issue discovery and improve team communication.

Virtual reality and human simulation at GM

Company: General Motors

Industry: Automotive and transportation

Location: Detroit, Michigan, USA

Siemens Software: Tecnomatix Process Simulate Human and Virtual Reality