Transformujte celý výrobní proces komponent pomocí jediného komplexního softwaru pro počítačem podporovanou výrobu (CAM).

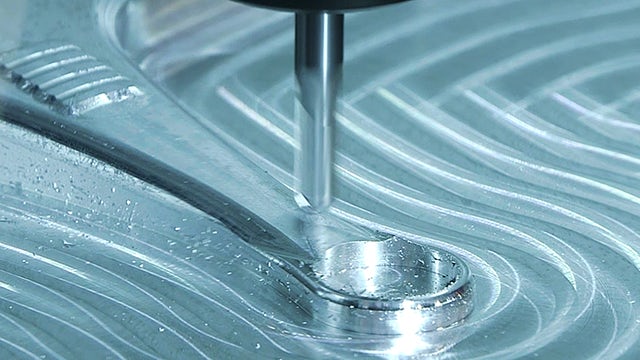

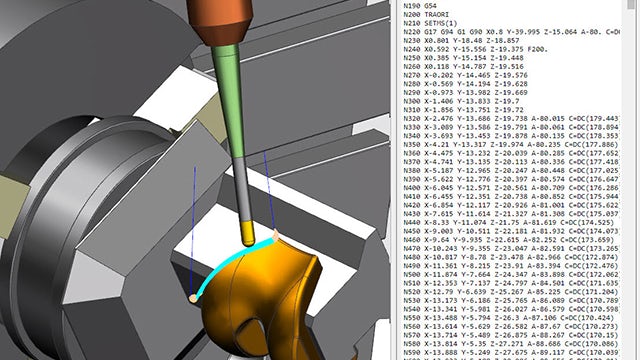

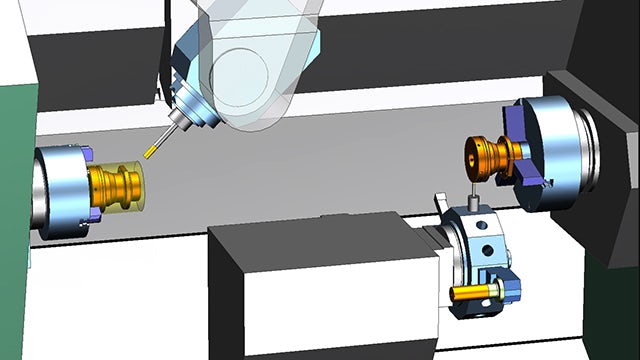

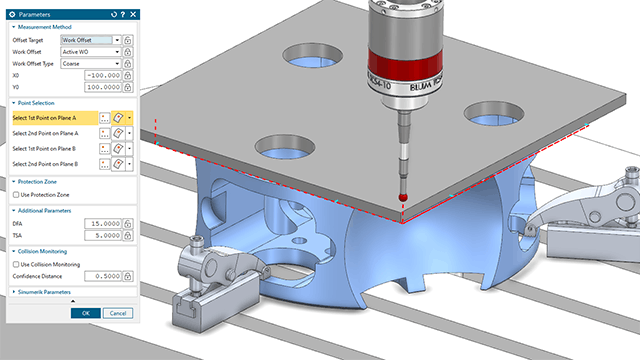

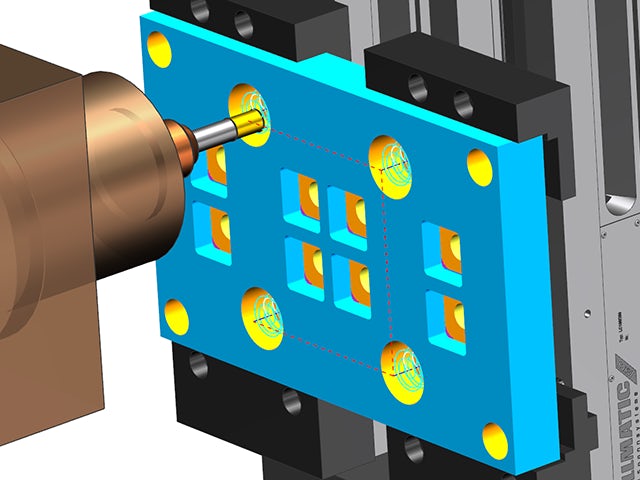

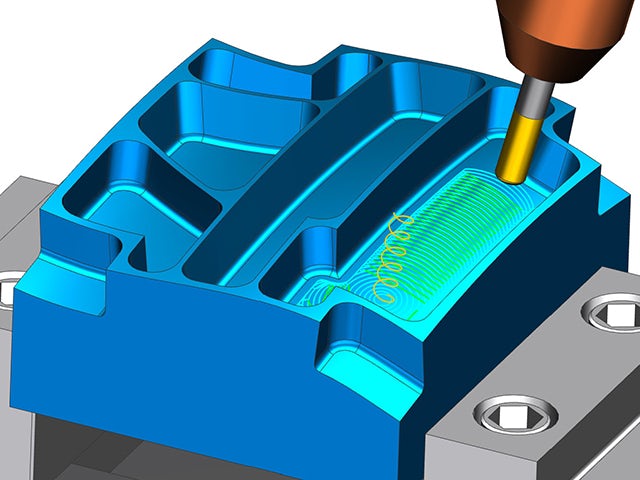

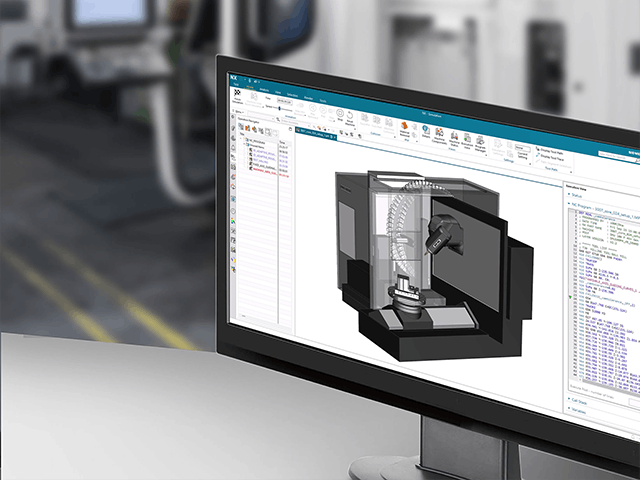

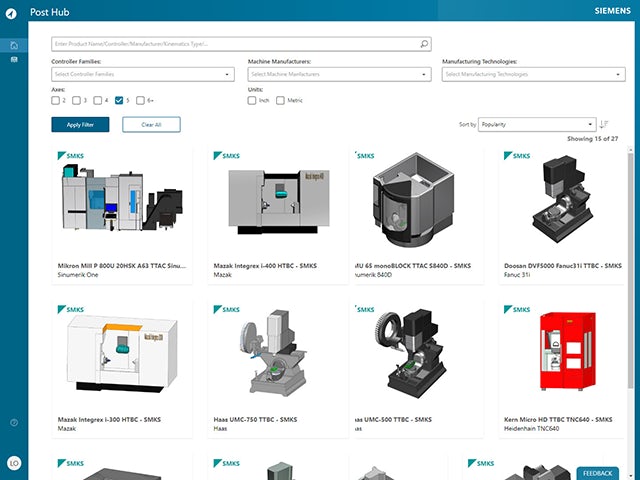

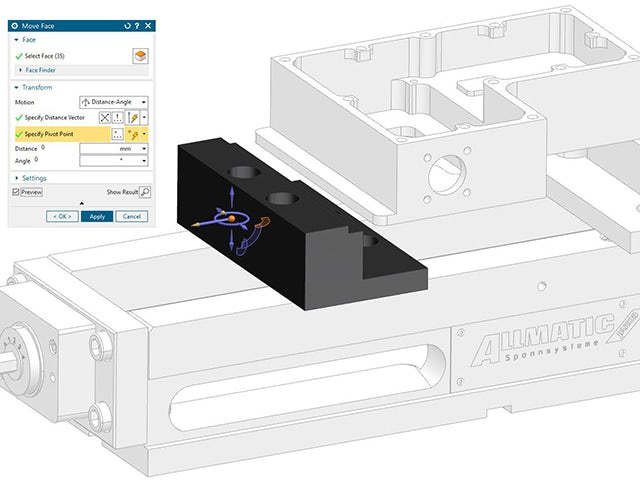

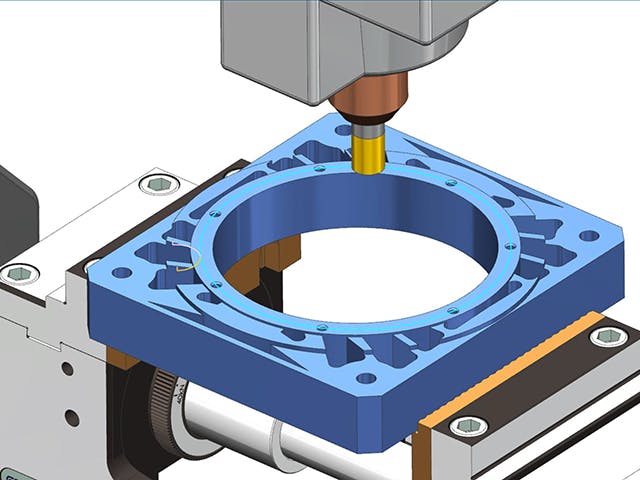

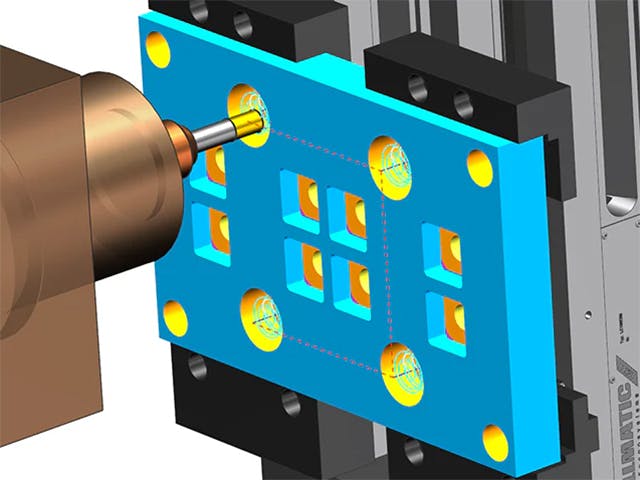

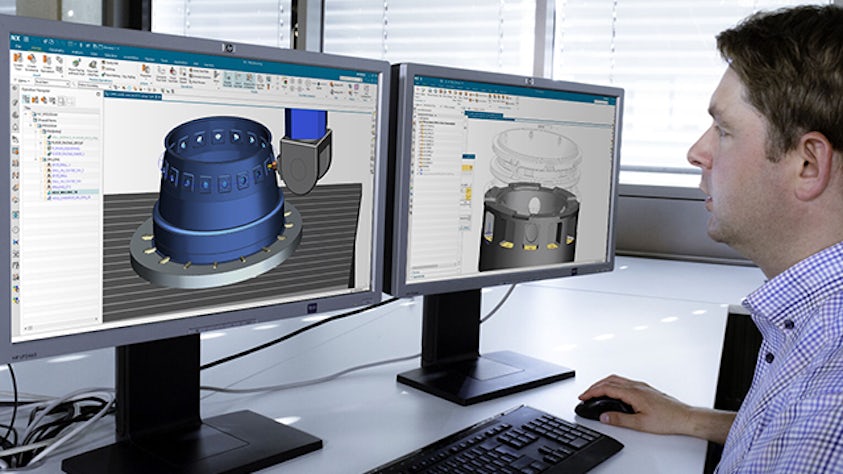

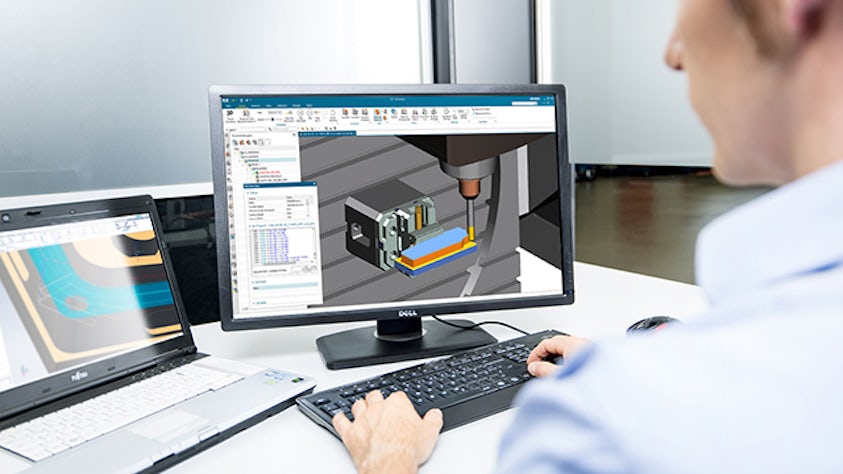

Software NX CAM pomáhá automatizovat NC programování, zrychlit obrábění a vyrábět vysoce přesné díly pomocí pokročilých technologií drah nástrojů a integrované simulace řízené G-kódem.

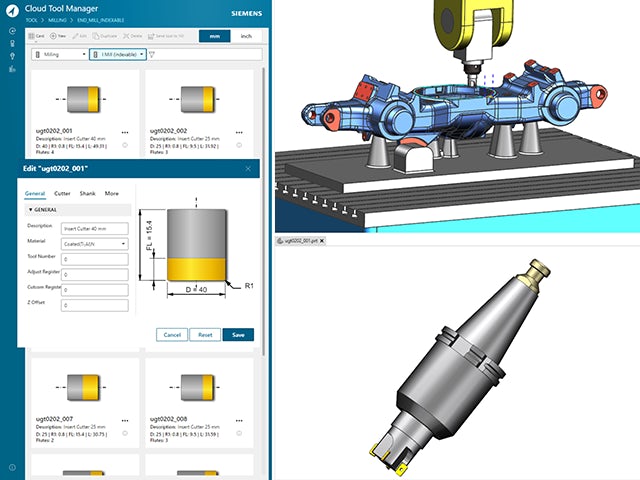

Umožněte svému týmu využívat NX X Manufacturing, řešení typu software jako služba (SaaS) nové generace, které kombinuje špičkový počítačem podporovaný návrh a výrobu (CAD/CAM) s flexibilitou, bezpečností a škálovatelností cloudových technologií.

Buďte o krok napřed díky bezproblémové integraci řešení NX CAM do našeho širšího řešení pro digitální výrobu. Řešte vyvíjející se potřeby průmyslu pomocí řady softwaru pro 3D tisk, robotiku, návrh výrobních linek a další činnosti.