Transformez l'ensemble de votre processus de fabrication de pièces à l'aide d'un logiciel de fabrication assistée par ordinateur (FAO) unique et complet.

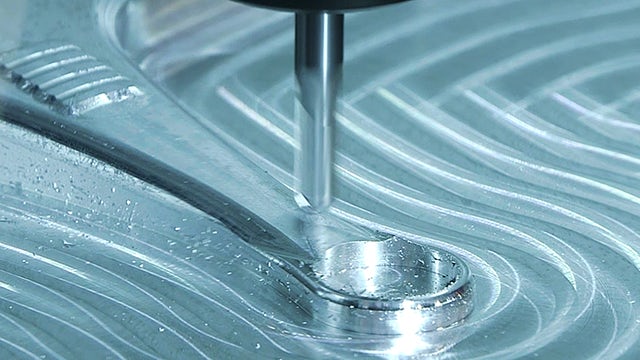

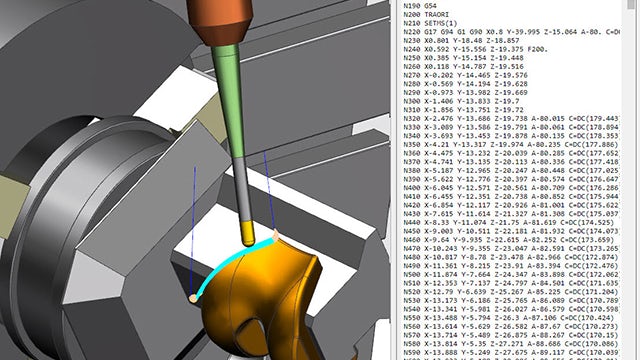

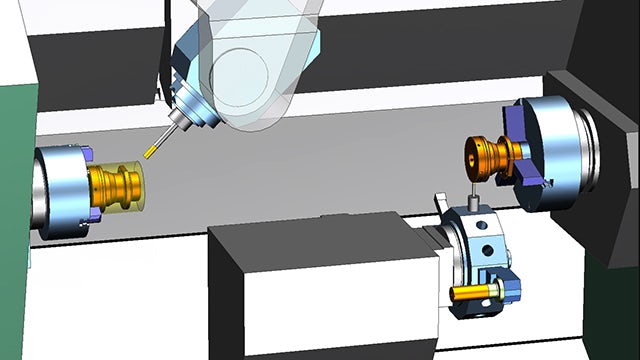

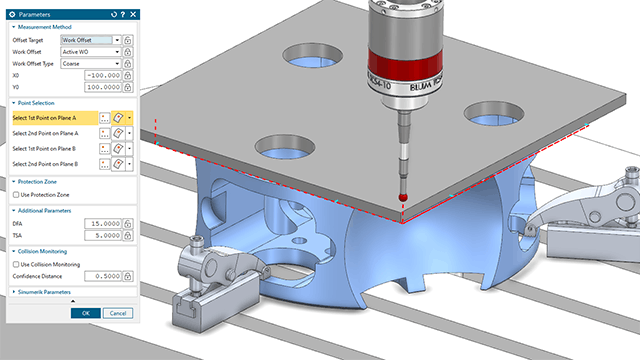

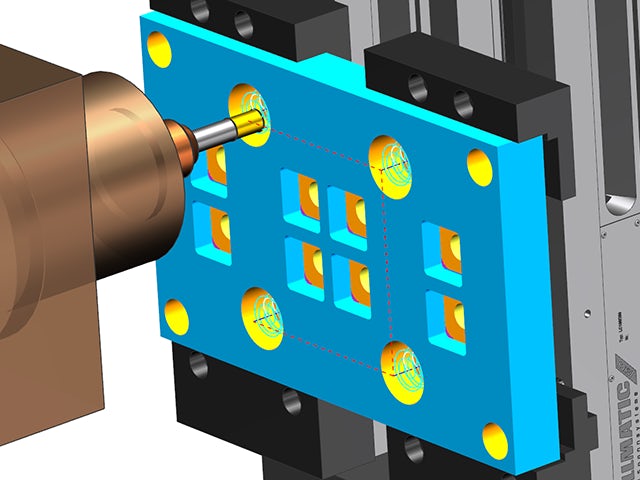

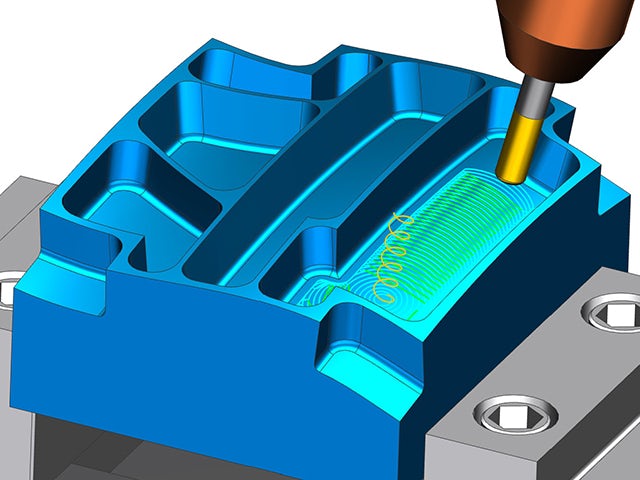

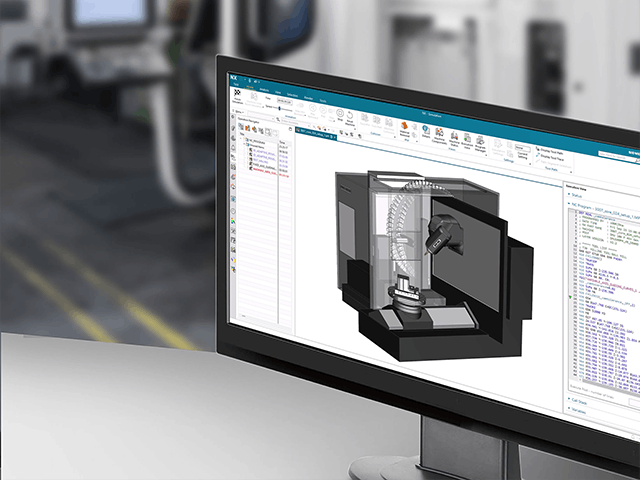

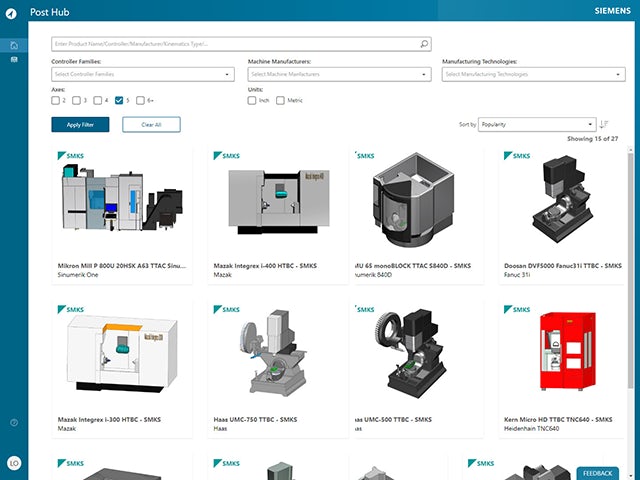

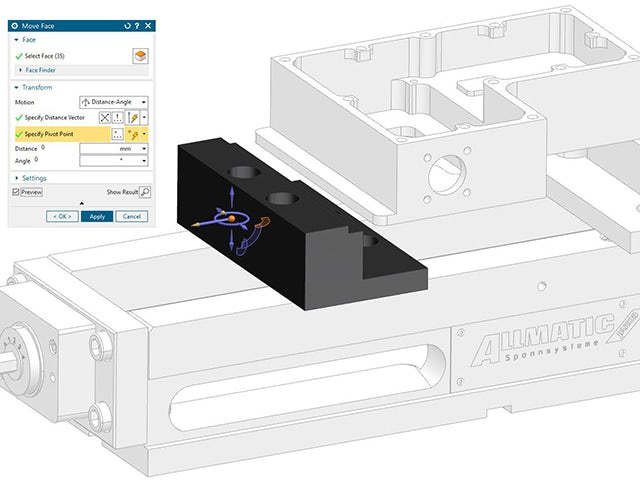

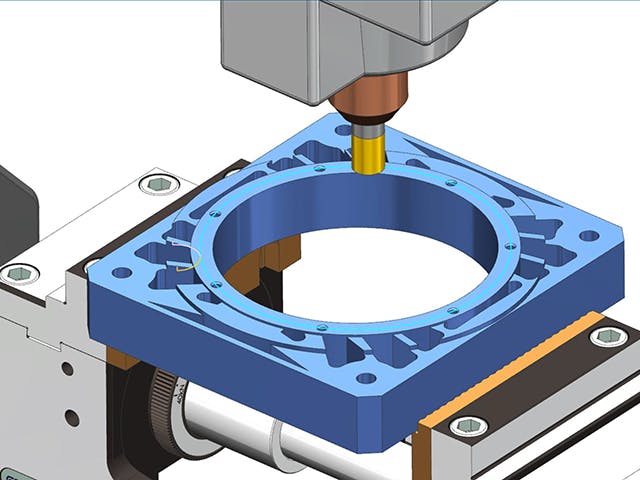

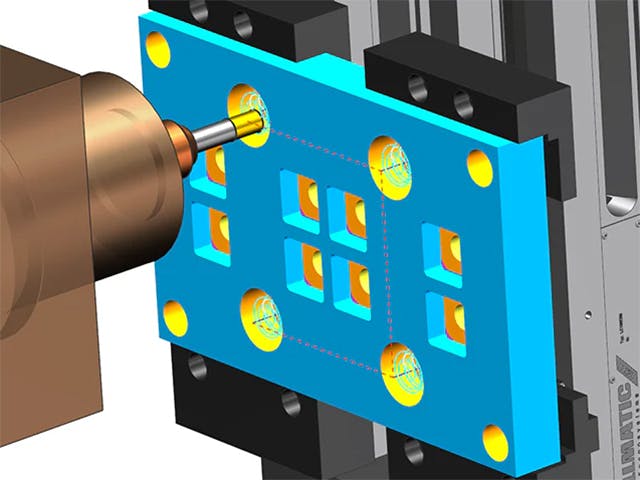

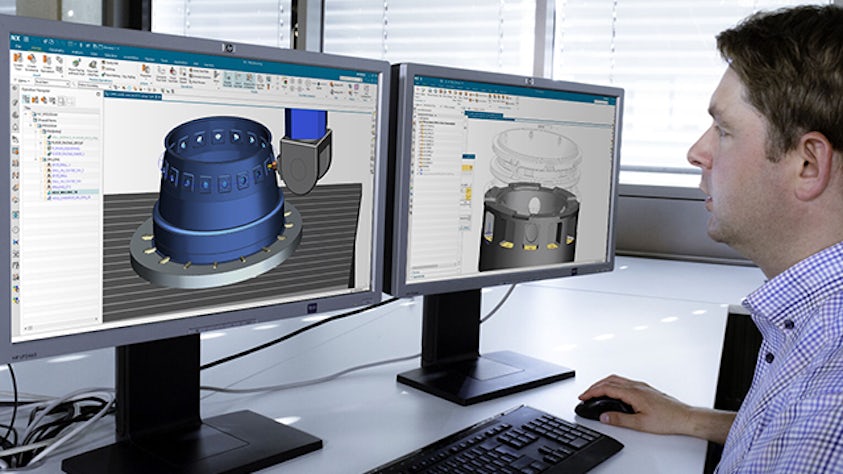

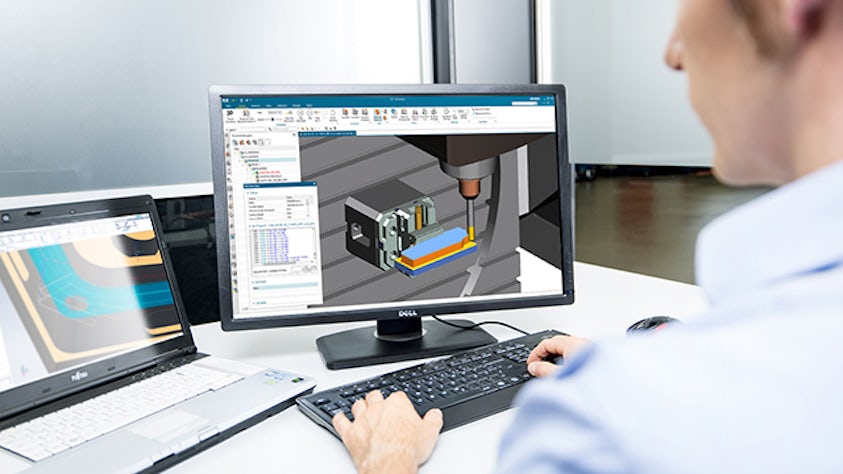

Le logiciel NX CAM permet d'automatiser la programmation CN, d'accélérer l'usinage et de fabriquer des pièces de haute précision à l'aide de technologies avancées de parcours d'outils et d'une simulation intégrée pilotée par code G.

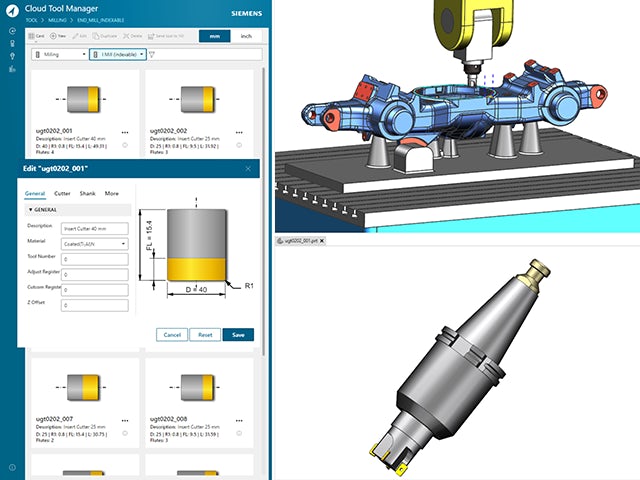

Dotez votre équipe de NX X Manufacturing, la solution de nouvelle génération en mode Software-as-a-Service (SaaS), qui combine la conception et fabrication assistées par ordinateur (CAO/FAO) leader du secteur avec la flexibilité, la sécurité et l'évolutivité des technologies cloud.

Gardez une longueur d'avance grâce à l'intégration transparente de NX CAM dans notre solution plus large de fabrication numérique. Répondez à l'évolution des besoins de l'industrie grâce à une gamme de logiciels pour l'impression 3D, la robotique, la conception de lignes de production et bien plus encore.