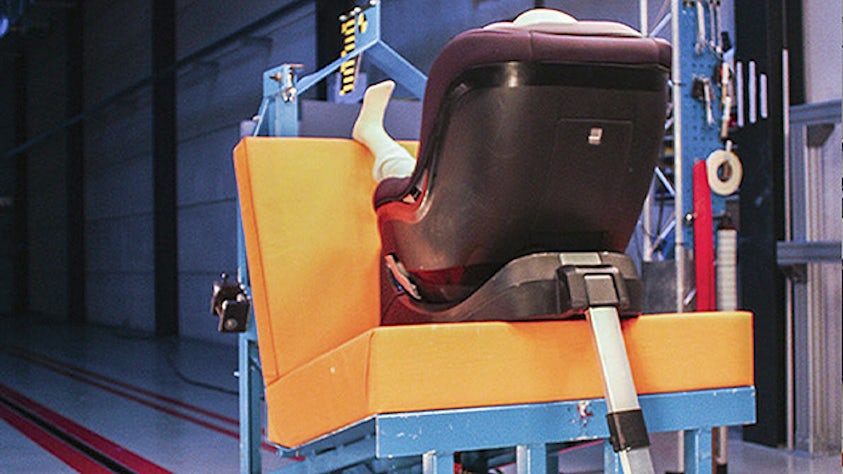

Nasza placówka w Helmond w Holandii wykonuje testy bezpieczeństwa z akredytacją EN ISO/IEC 17025 (nr rejestracyjny L547) na potrzeby certyfikacji przez laboratorium z akredytacją RDW (E4) i KBA (E1); oferujemy szeroki zakres testów bezpieczeństwa komponentów i układów, od kasków po kompletne układy zabezpieczające. Oprócz testów w trakcie procesu rozwoju przeprowadzamy także ostateczną i niezależną weryfikację zgodności produktu z globalnymi standardami.

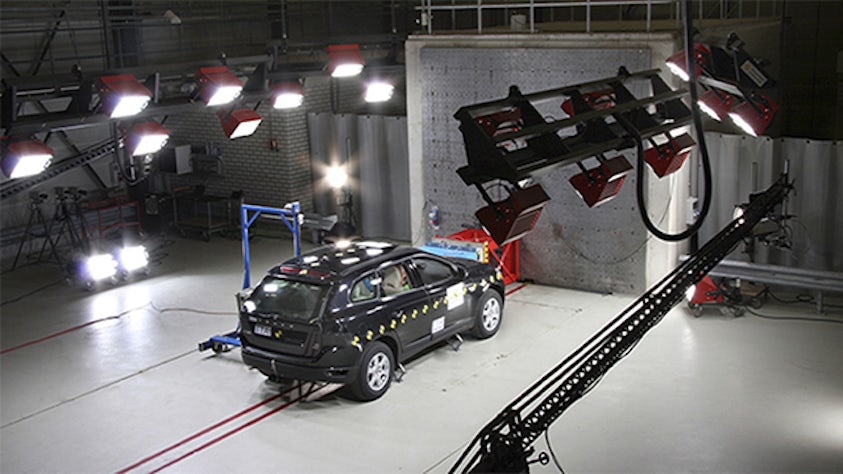

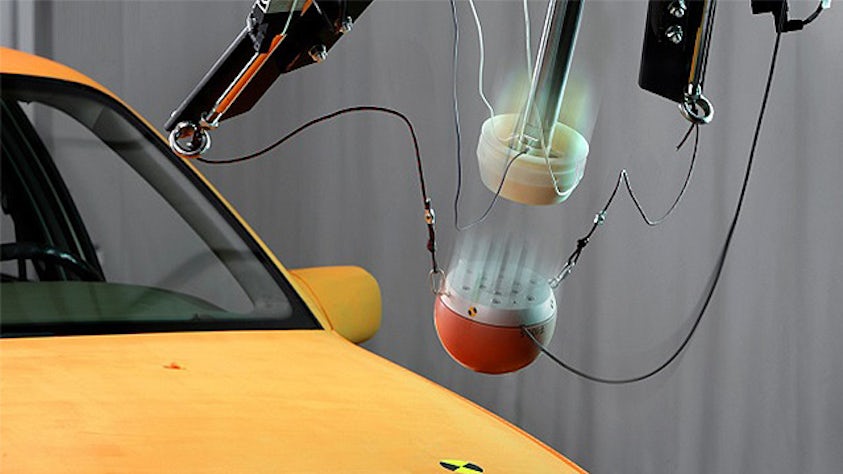

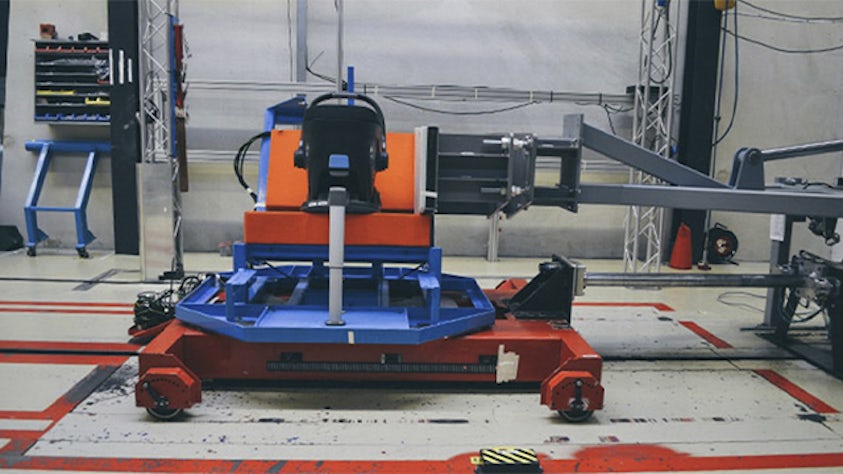

Oprócz testowania określonych podzespołów związanych z bezpieczeństwem testujemy ogólne bezpieczeństwo pojazdu. Bazując na ponad 30-letnim doświadczeniu, oferujemy oprogramowanie symulacyjne oraz wiedzę i narzędzia do opracowywania, projektowania, testowania i walidacji różnych systemów bezpieczeństwa biernego i aktywnego. Nasze ośrodki testowe są w pełni wyposażone do wykonywania szerokiego zakresu testów na potrzeby branży motoryzacyjnej, zarówno do zastosowań wewnątrz, jak i na zewnątrz pojazdu.