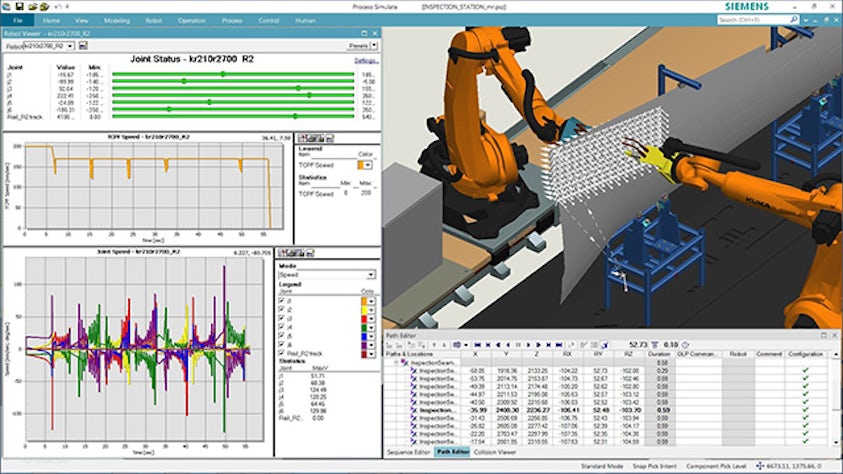

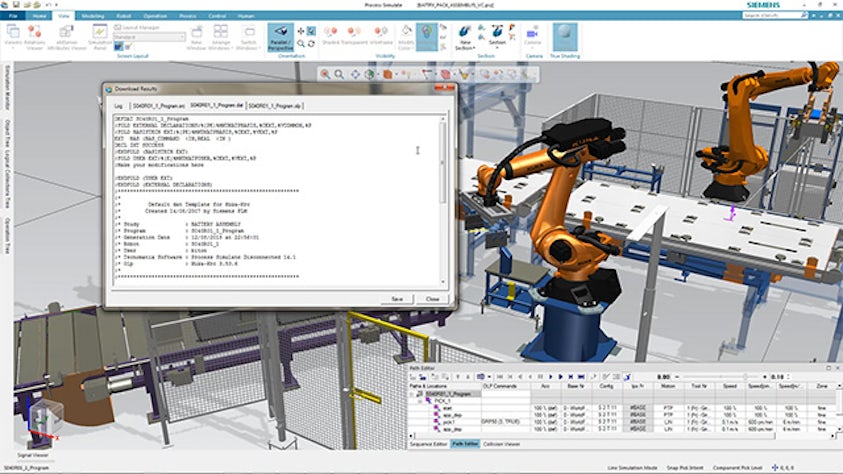

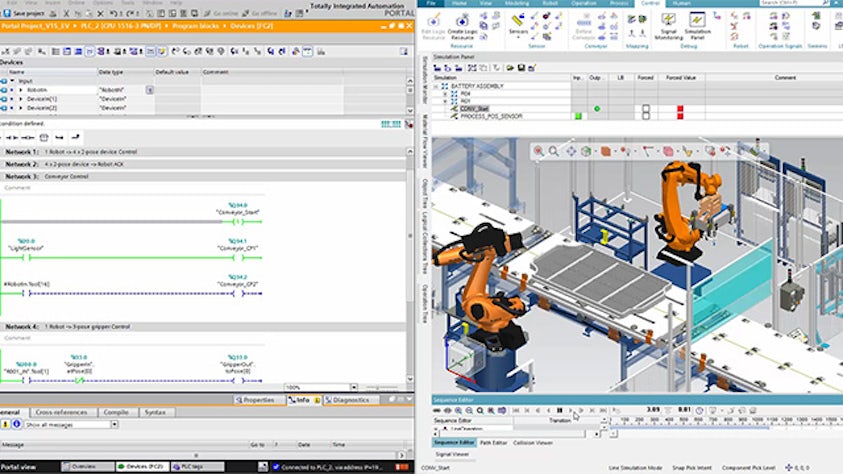

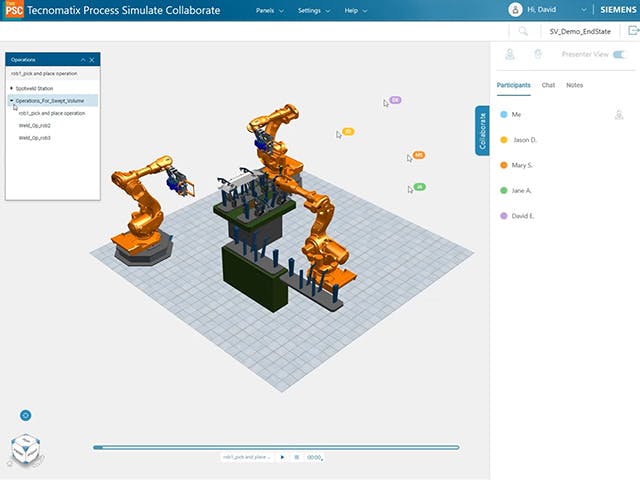

Rozwiązanie pozwala przyspieszyć wprowadzanie produktów na rynek, umożliwiając inżynierom produkcji prowadzenie wirtualnej walidacji koncepcji wytwarzania przed jego rozpoczęciem i w całym cyklu życia produktu.

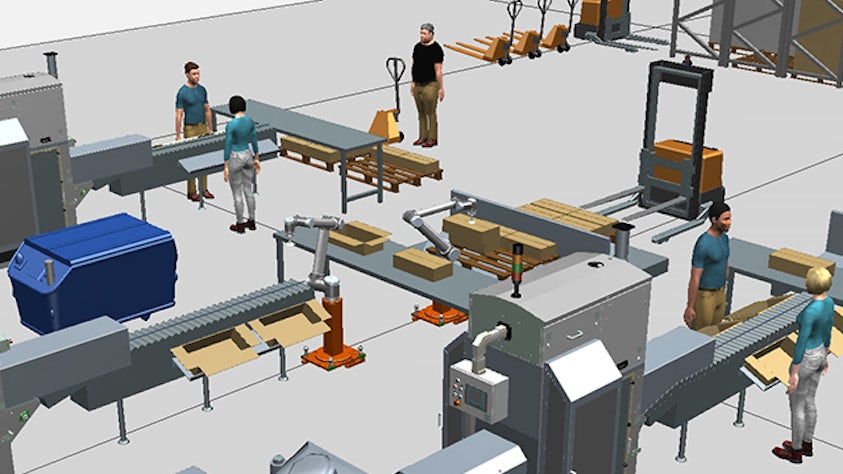

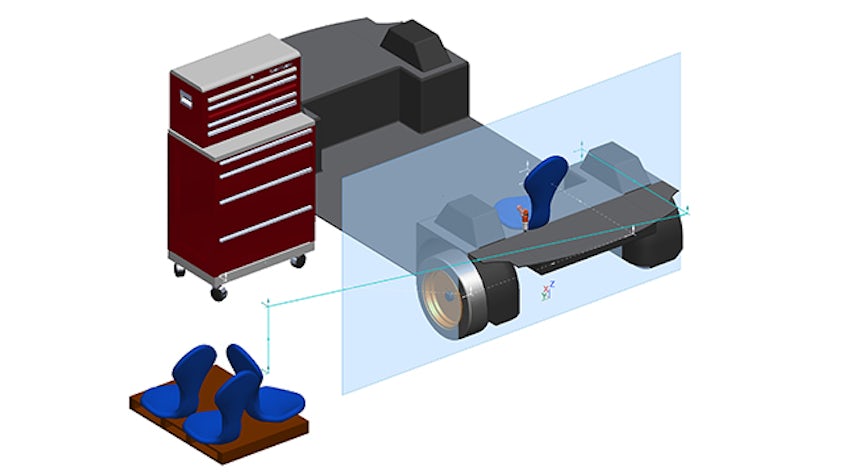

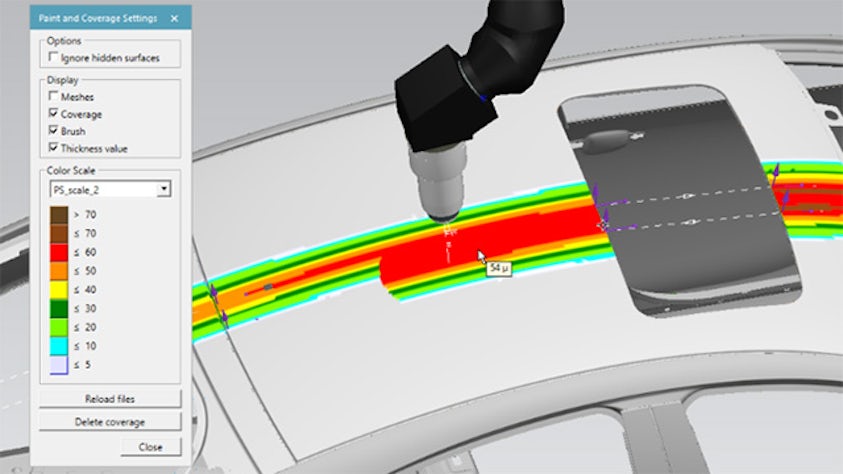

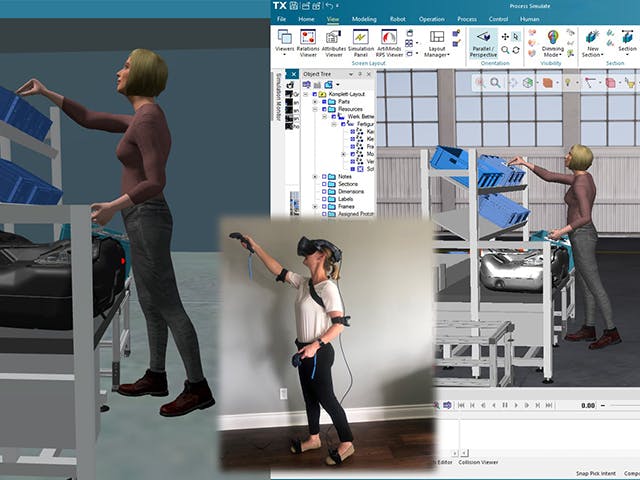

W tym celu można wykorzystać modele 3D produktów i zasobów, aby ułatwić symulację, walidację, optymalizację i uruchamianie złożonych procesów produkcji z udziałem maszyn i ludzi oraz przyspieszyć wprowadzanie na rynek produktów o wyższej jakości.