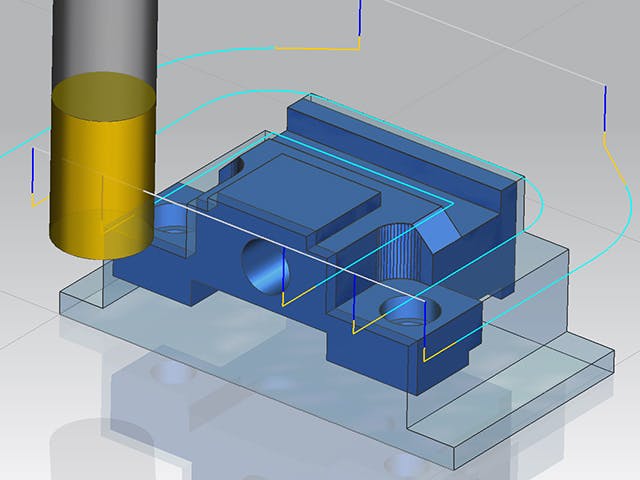

Automate programming of prismatic parts using a fully integrated CAD/CAM system featuring advanced capabilities for 2.5-axis milling.

Automate programming

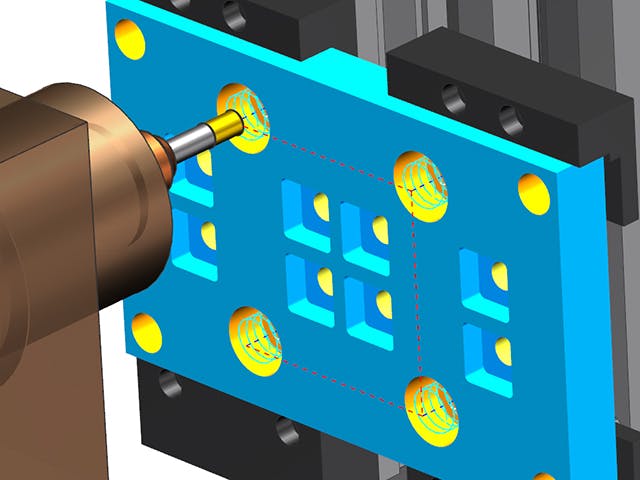

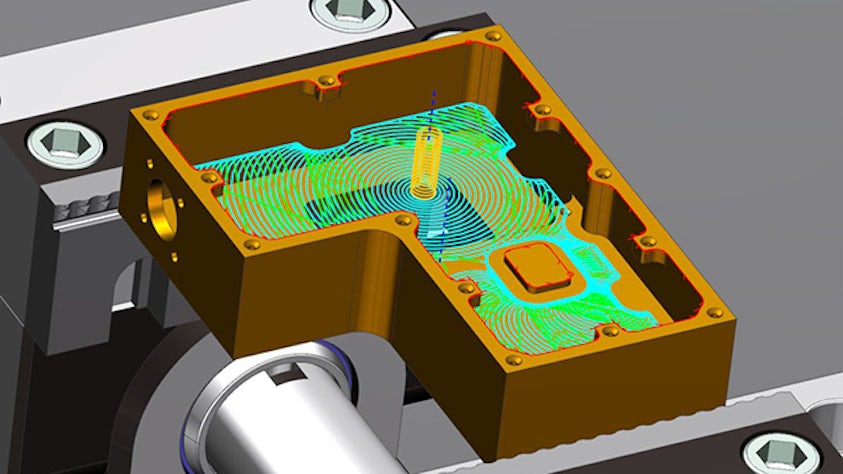

Reduce programming time by up to 90% using automated NC programming capabilities, including feature-based machining, volume-based milling and chamfering. You can simplify programming of the most demanding jobs by programming in the context of the machining setup and using the In-Process Workpiece (IPW) technology.

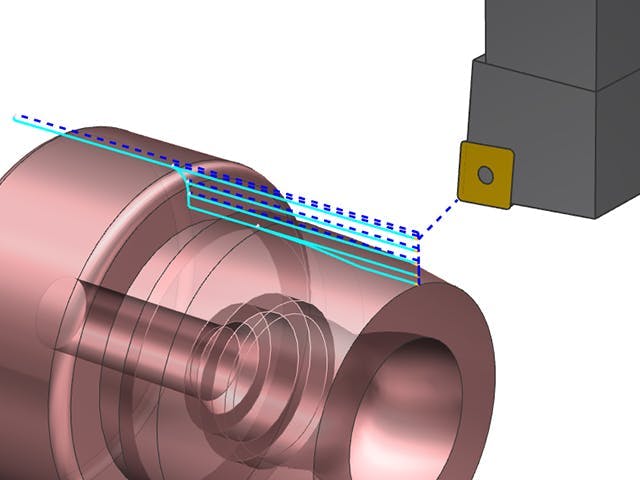

Accelerate machining

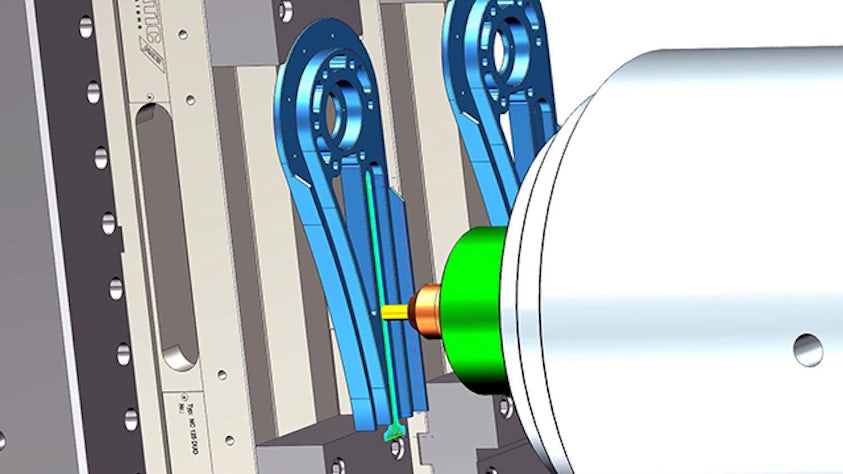

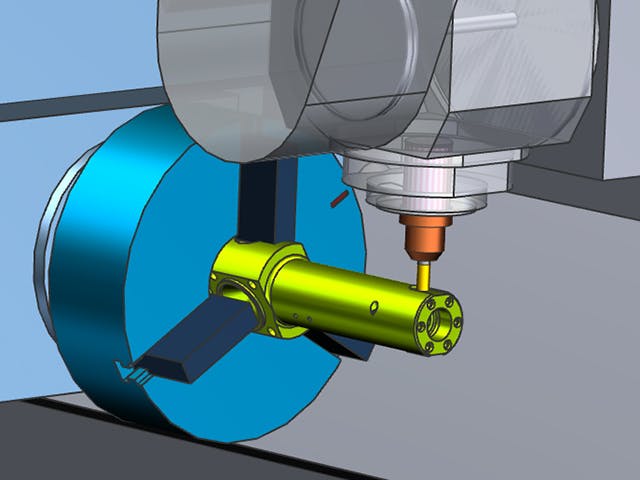

Generate highly efficient machining operations that can accelerate part production using the latest technologies for high-speed cutting, multiple-part machining and 3+2 positioning.

Design with integrated CAD

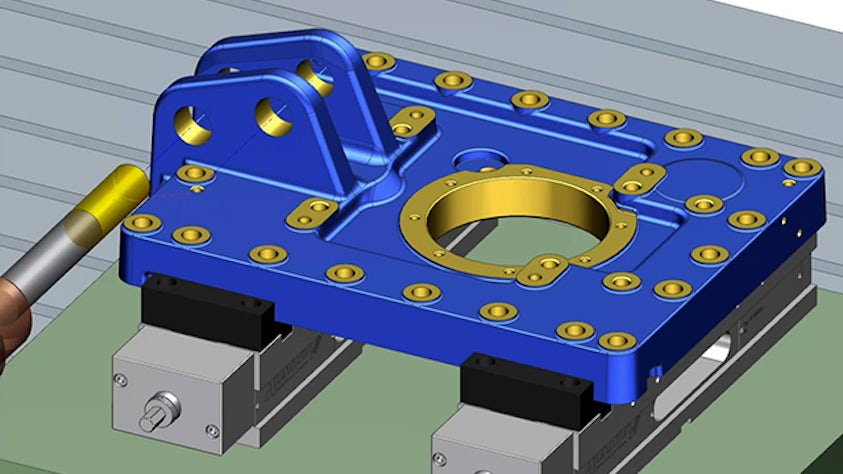

Design and prepare CAD models for NC programming with integrated modeling and editing tools, such as synchronous technology. Using the integrated 3D design tools, model the fixture components, including clamps and vises. The assembly tools help you define the machine setup digital replica, enabling optimized and collision-free toolpaths.

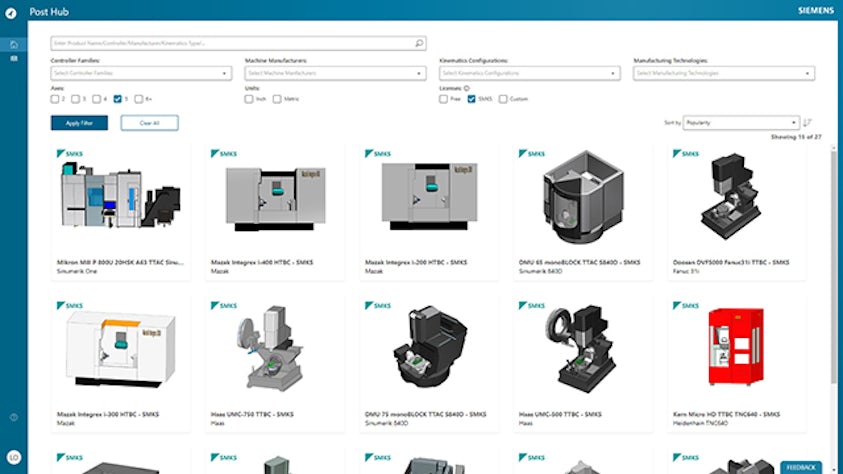

Output validated programs

Digitally validate the toolpaths using integrated machining simulation. Output machine-specific NC programs using Post Hub, a cloud-based postprocessing solution. Create complete and associative shop documentation, including tool lists, setup sheets and 3D drawings.

NX CAD/CAM provides advanced programming capabilities for 2.5-axis milling, including:

- Feature-based machining

- Volume-based milling

- High-speed machining

- Automated deburring

- Hole-making operations

- Multiple part machining

- Multi-stage machining

- Z-level finishing

- 3+2 positioning

- In-Process Workpiece

- Feed rate optimization

- Machining simulation

- Postprocessing

- Probing cycles

Included integrated CAD tools:

- Synchronous technology

- Assemblies

- CAD translators

- Freeform modeling

- Design simulation

- Product and manufacturing information (PMI)

- Drafting