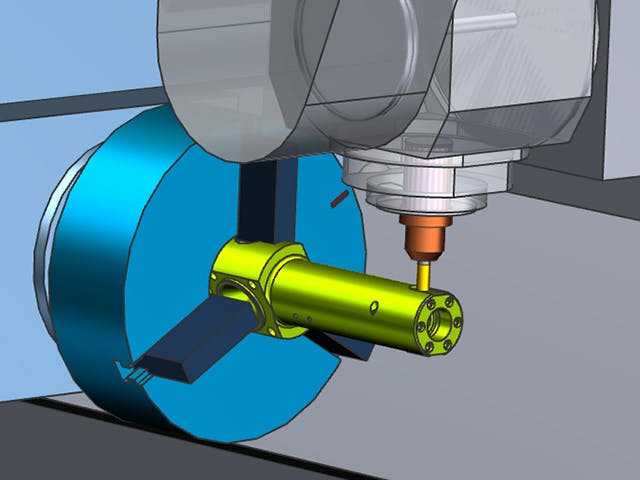

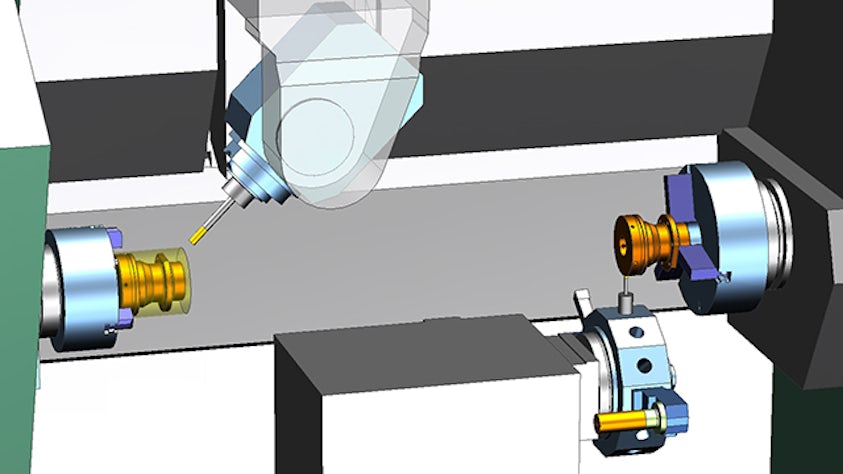

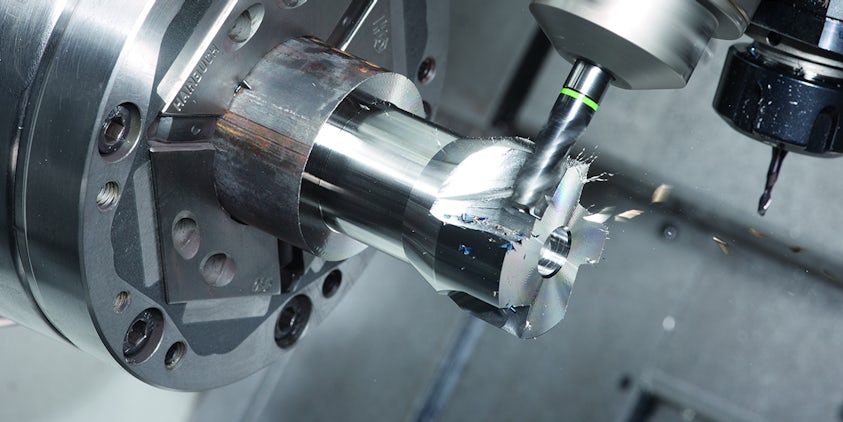

Use a complete range of machining capabilities to program the latest multi-function machines with multiple spindles and channels. These machines with mill-turn capabilities enable machining of a complete part in a single setup, saving time and improving part accuracy.

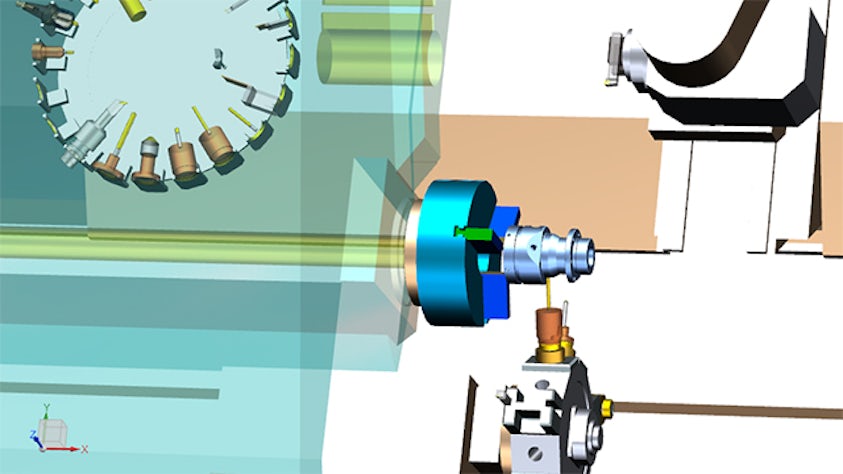

Program multi-channel operations

Use the Synchronization Manager's interactive controls to synchronize operations across multiple channels. Reduce cycle times for multi-channel machines by optimizing sync codes.

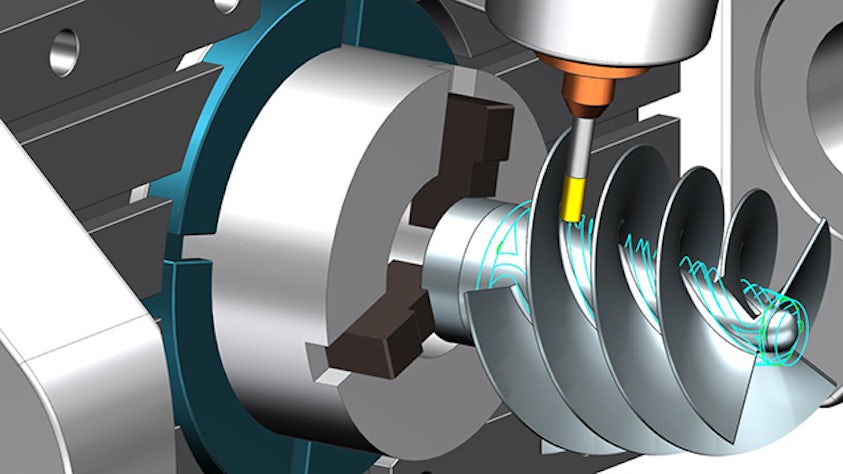

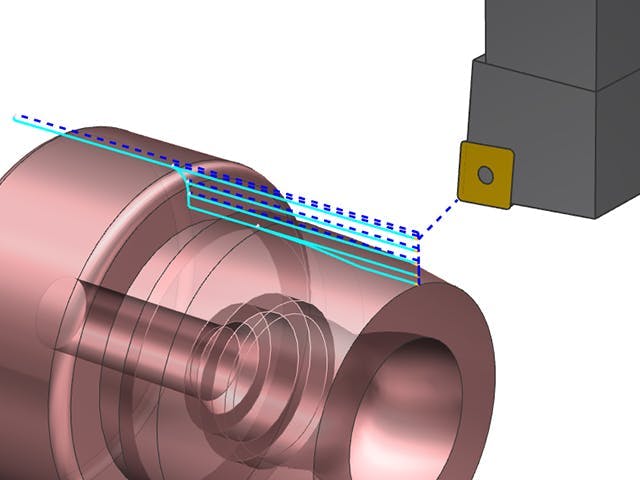

Track cut material

Keep track of the in-process state of the workpiece for a more effective mill-turn programming. The automatically generated In-Process Workpiece (IPW) allows seamless transfer of workpiece configurations between milling and turning.

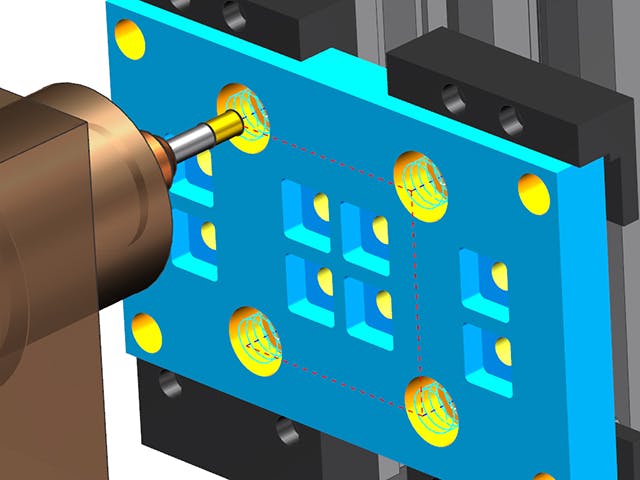

Design with integrated CAD

Use the integrated CAD capabilities to design part models and fixtures. Define the machine setup with the assembly tools, enabling optimized and collision-free toolpaths. Prepare CAD models for NC programming with powerful editing tools, such as synchronous technology.

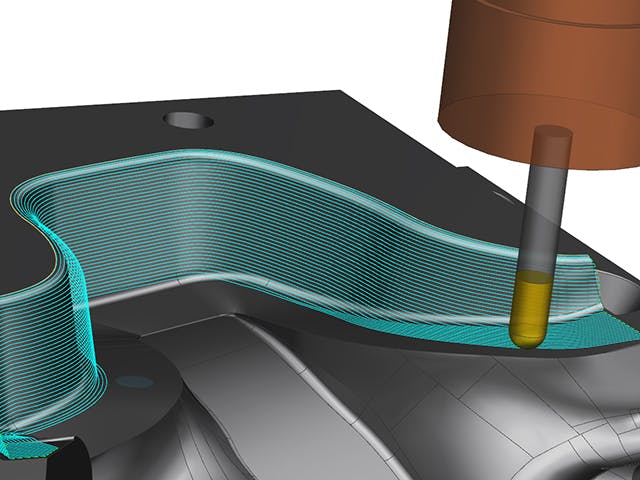

Output validated programs

Accurately simulate mill-turn operations using integrated machining simulation. Generate machine-specific NC programs using Post Hub, a cloud-based postprocessing solution. Transfer the manufacturing data to production by creating a complete shop documentation, including tool lists, setup sheets and 3D drawings.

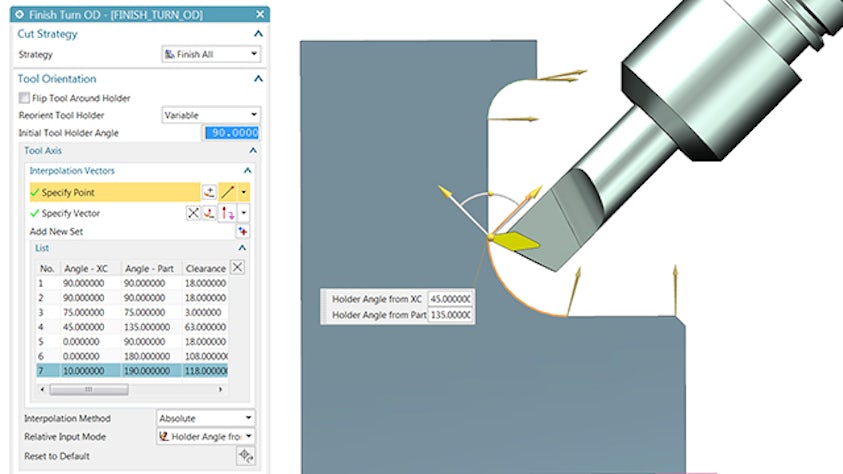

NX CAM provides advanced programming capabilities for mill-turn, including:

- Turning capabilities

- 2.5-axis milling capabilities

- 2.5-, 3- and 4-axis deburring

- 4-axis rotary milling

- Synchronization manager

- In-Process Workpiece

- Machining simulation

- Postprocessing

Additionally, NX offers integrated CAD tools, such as:

- Synchronous technology

- Assemblies

- CAD translators

- Freeform modeling

- Design simulation

- Product and manufacturing information (PMI)

- Drafting