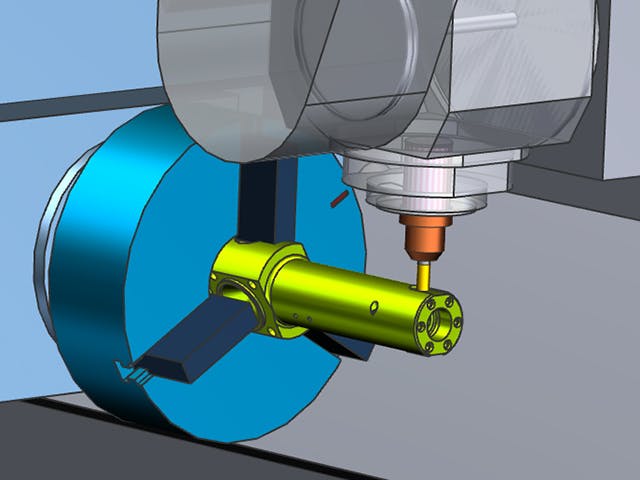

Leverage the flexible turning solution to quickly program simpler jobs as well as the most challenging multi-spindle, multi-turret applications. Program A-axis and B-axis turning operations.

Program advanced turning operations

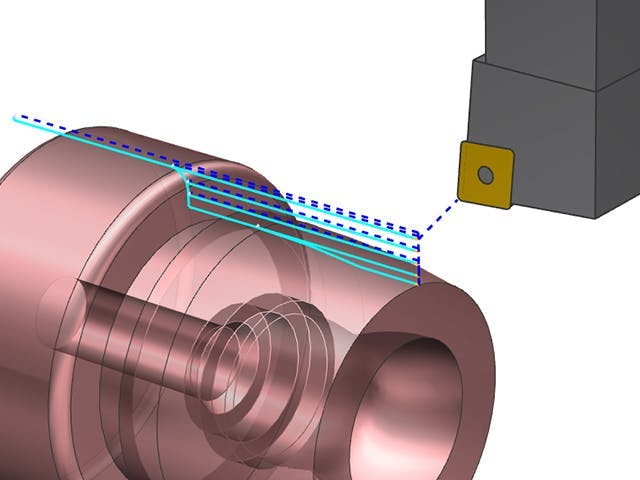

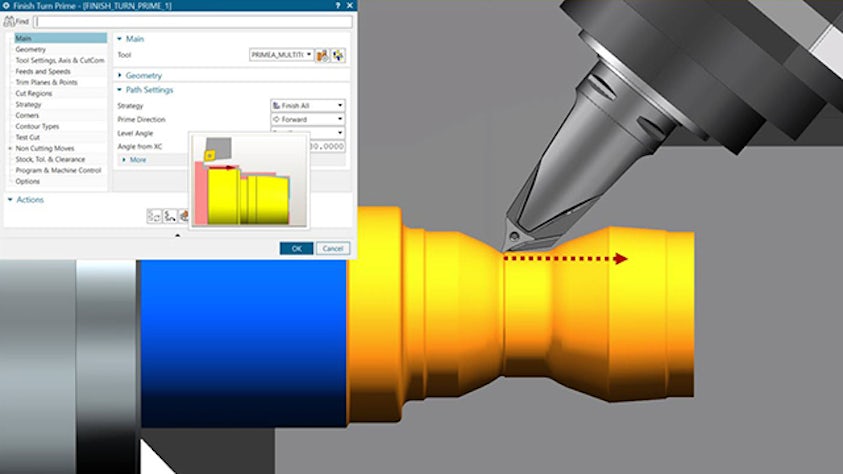

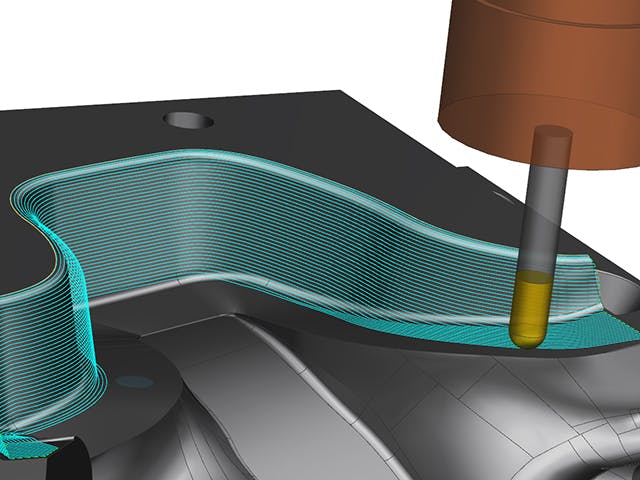

Use either 2D part profiles or full solid models to program roughing, multiple pass finishing, grooving, thread cutting and centerline drilling operations. Innovative turning methods, such as PrimeTurning, can accelerate machining and improve productivity by up to 50%.

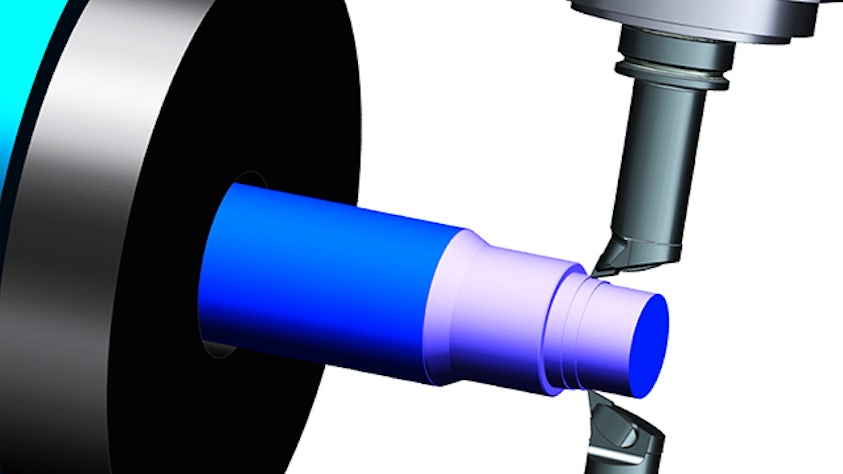

Automatically track turning volumes with the In-Process Workpiece (IPW) technology, enabling 3D visualization and efficient handling of design changes.

Design with integrated CAD

Model parts, blanks, fixtures and complete machine setups using integrated CAD for modeling and assembly. Prepare part models for NC programming using synchronous technology.

Output validated programs

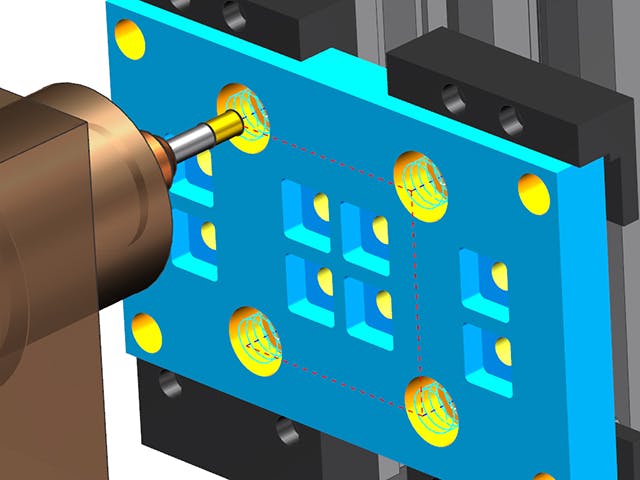

Generate validated, production-ready NC programs, using the cloud-based postprocessing solution and integrated machining simulation. Digitally connect planning and production with associative shop documentation, including tool lists and setup sheets.

NX CAM provides advanced programming capabilities for turning, including:

- Roughing: face, turn, back turn, bore, back bore and undercut

- Finishing: face, turn and bore

- Hole making: spot, drill, peck, chip, ream and tap

- Grooving: with flexible tracking point control

- Threading of outer and inner diameters (OD/ID)

- Cutoff and bar feed operations

- PrimeTurning

- Pinch turning

- A-axis and B-axis tool control

- In-Process Workpiece

- Toolpath verification

- Postprocessing

Additionally, NX offers integrated CAD tools, such as:

- Synchronous technology

- Assemblies

- CAD translators

- Freeform modeling

- Design simulation

- Product and manufacturing information (PMI)

- Drafting