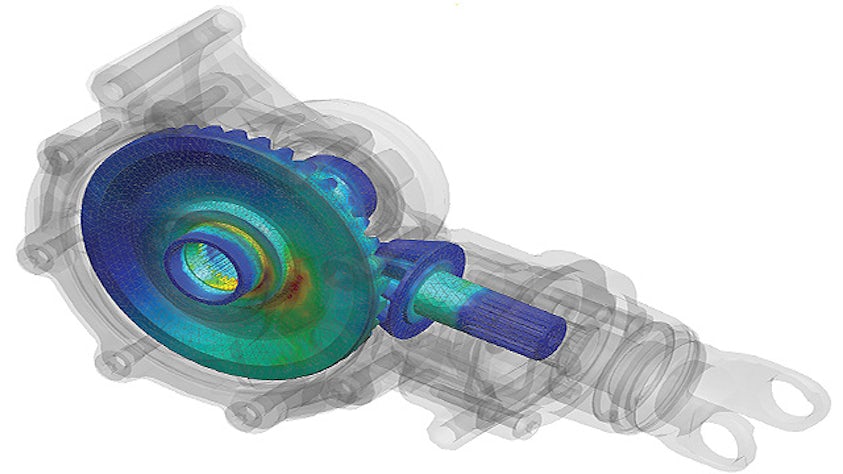

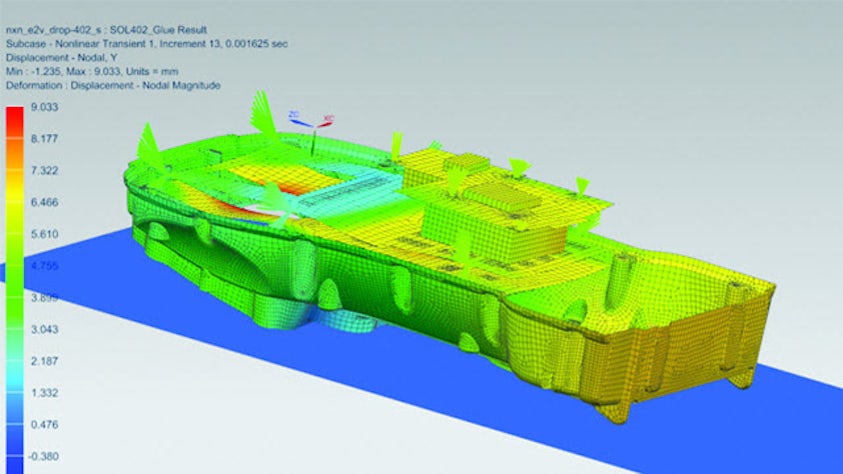

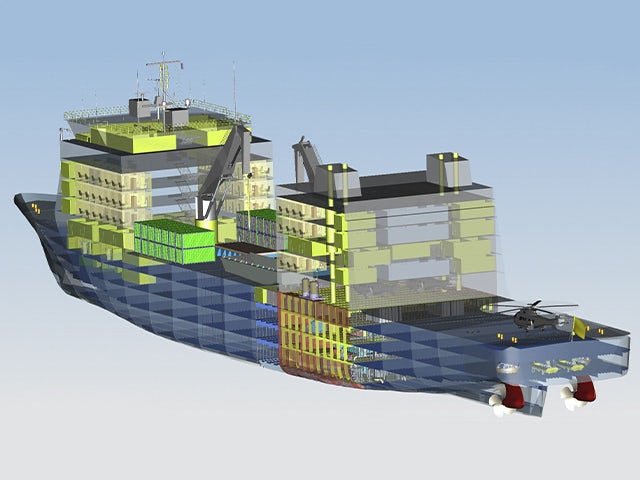

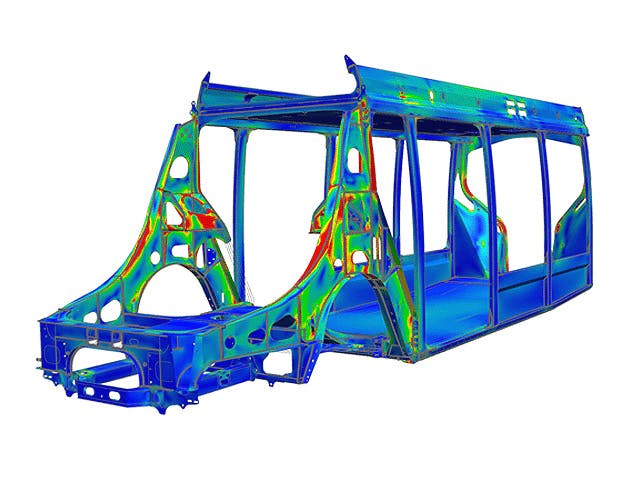

Structural analysis simulation is the study of the effects of weight and tension on a structure. Understanding how a component or product assembly reacts under stress or vibration is critical in any industry. However, as products and materials become increasingly complex, engineers need tools that go beyond linear-statics analyses.

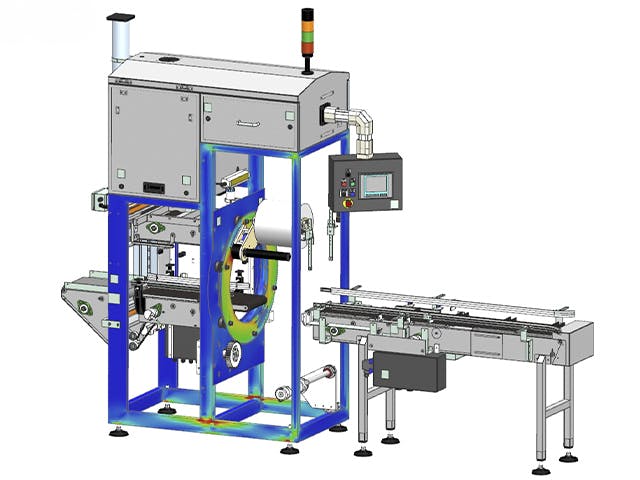

Simcenter provides the structural analysis software you need to simulate a wide range of applications, all within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. As a result, engineering departments can consolidate structural analysis tools, and you only need to know a single user interface.

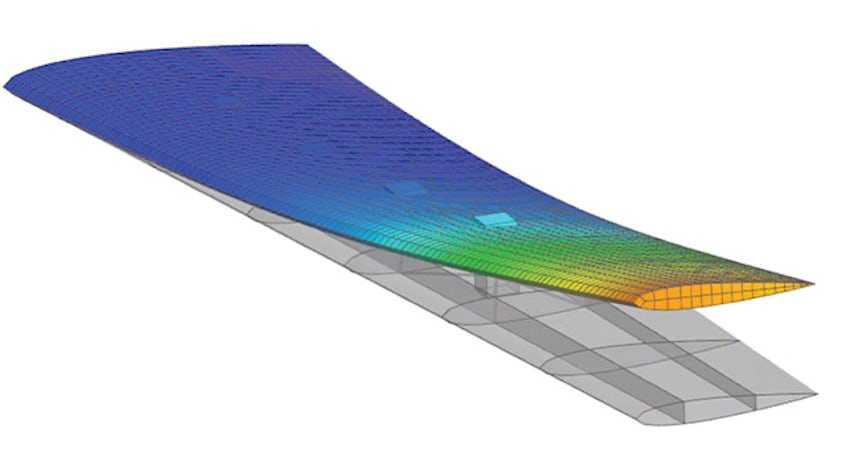

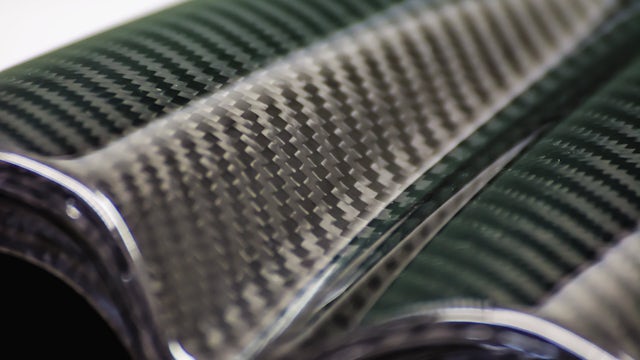

Aircraft structural design and analysis

Moving from fossil fuel-powered aviation to sustainable aviation constitutes a massive engineering challenge but is required to stay competitive. Learn about a connected airframe structural design and analysis approach to enable the evolution of sustainable aviation.