Proč využívat řešení Kineo?

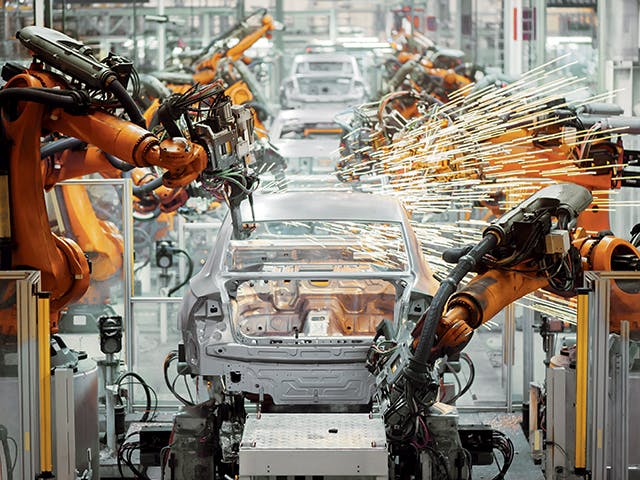

Projděte si naše portfolio softwarových komponent řešení Kineo pro automatické plánování pohybu, detekci kolizí a simulaci flexibilních kabelů. Tyto technologie jsou integrované do softwarových aplikací pro automobilový, letecký, energetický, lodní a výrobní průmysl. Můžete je využít k simulaci průmyslových robotů, vytváření digitální makety, ověřování sestavování/demontáže a studiím přístupnosti.

Bohatý rámec grafického uživatelského rozhraní (GUI) umožňuje výrobcům OEM, systémovým integrátorům a dodavatelům softwaru snadno vyvíjet vlastní softwarové aplikace založené na komponentách řešení Kineo, a to s nižším rizikem a kratší dobou uvedení na trh.

Objevte výhody řešení Kineo

Zvýšení produktivity

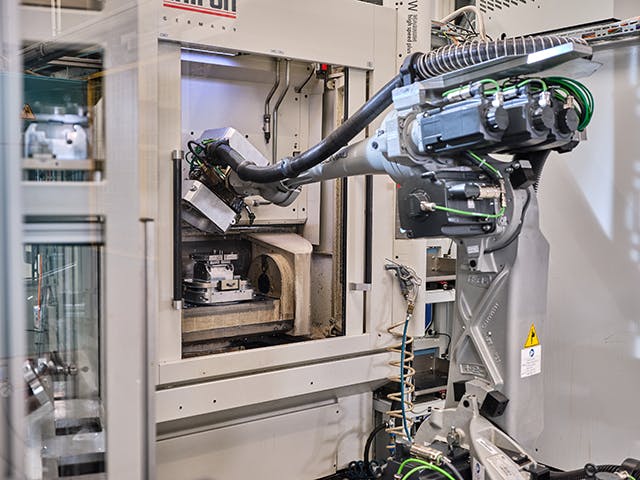

Vypočítejte rychlé a energeticky úsporné časy cyklů pro průmyslové roboty, souřadnicové měřicí stroje a obráběcí stroje.

Minimalizace prostojů

Omezte prostoje ve výrobě díky bezkolizním výpočtům trajektorie a prediktivnímu výkonu kabelů.

Rychlejší vývoj aplikací

Urychlete vývoj své softwarové aplikace pro robotiku nebo digitální makety pomocí našich osvědčených průmyslových softwarových komponent.

Projděte si nabídku produktů Kineo

Podpořte širokou řadu aplikací

Zůstaňte ve spojení díky řešení PLM Components

Přečtěte si blog

Získejte novou perspektivu o řešení PLM Components a trhu se systémy PLM v obecné rovině.