Simcenter Testlab Neo bietet eine neue aufgabenorientierte Benutzererfahrung und erweitert die Entwicklungsfunktionen um End-to-End-Tests der Lebensdauer, intuitives NVH-Performance Engineering (Noise, Vibration and Harshness) und modellbasierte Tests.

Nutzen Sie testbasiertes Performance Engineering

Simcenter Testlab Neo ist die Softwareplattform der nächsten Generation für multidisziplinäres, testbasiertes Performance Engineering. Es integriert jahrelange Entwicklungserfahrung in eine neue Umgebung, die mehr Produktivität, mehr Einblicke, mehr Vertrauen und eine einfachere Zusammenarbeit bietet.

Beschleunigen Sie die Interpretation der Ergebnisse

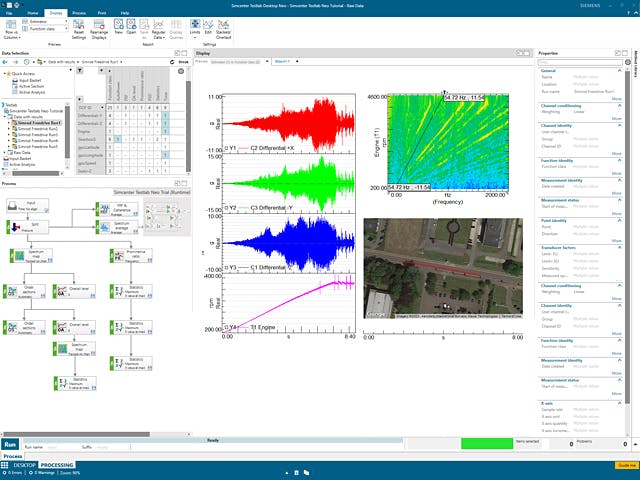

Die neue aufgabengesteuerte Benutzererfahrung erleichtert die Arbeitsproduktivität und die allgemeine Navigierbarkeit. Ein vollständig anpassbarer und flexibler Prozesskonstrukteur beschleunigt die Analyse, unterstützt multidisziplinäre Analysen und bettet Simulationsmodelle in jeden Prozessablauf ein. Intuitive und interaktive Diagramme, die direkt mit Ihren lokalen Ergebnissen oder Ihren zentralisierten Daten verbunden sind, beschleunigen die Interpretation der Ergebnisse und unterstützen den technischen Entscheidungsprozess.

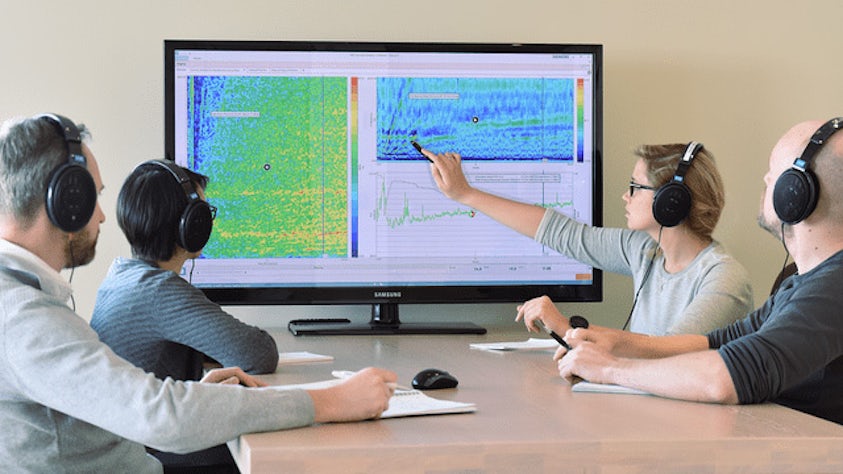

Simcenter Testlab Neo für intuitives Sound Quality Engineering

Die Klangqualität ist ein wichtiger Aspekt der Produktentwicklung. Erfahren Sie, wie Simcenter Testlab Neo Sound Quality Engineering intuitiver als je zuvor macht.