Simcenter 3D helps you model and evaluate complex product performance through revolutionary improvements in simulation efficiency. By integrating multiple physics domains together from a single simulation modeling environment, you gain better insight into your products’ performance faster.

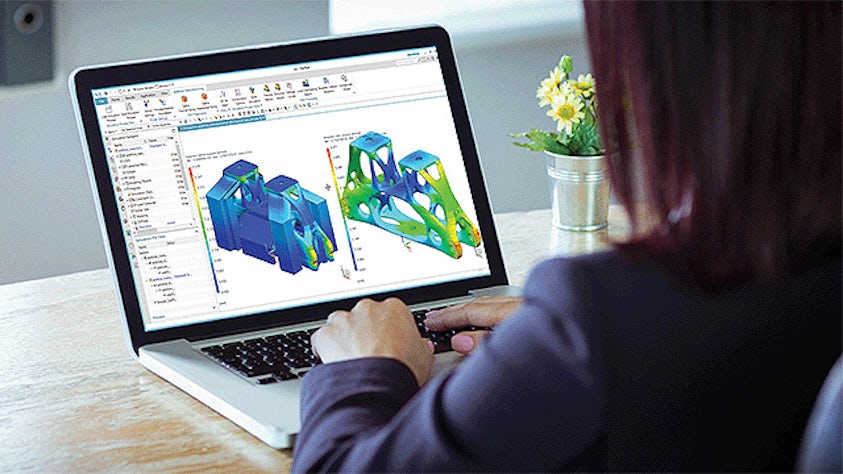

Go faster – through a common engineering desktop

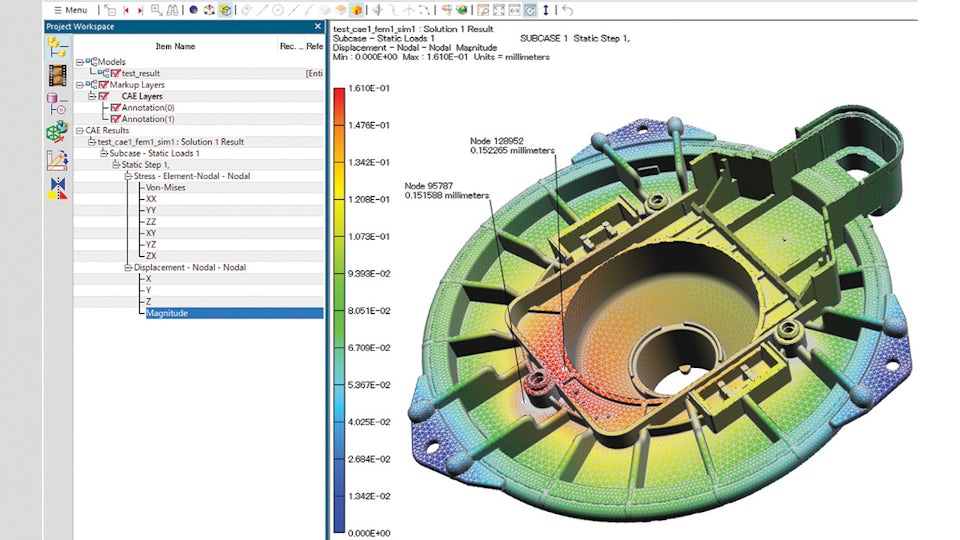

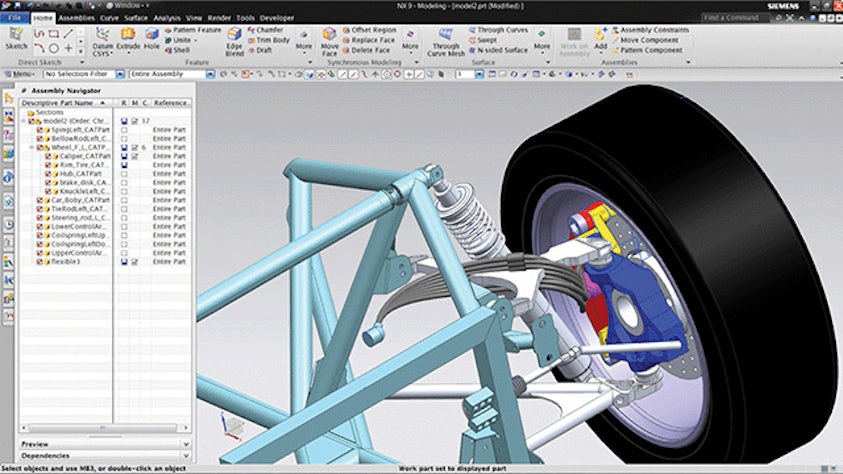

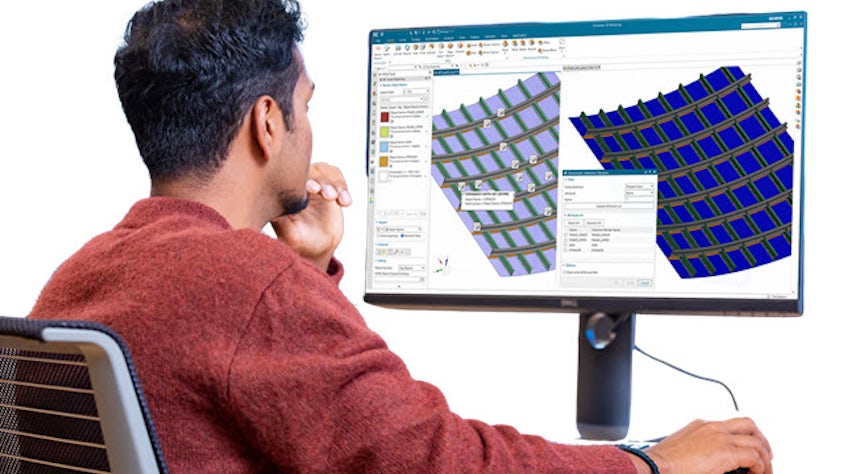

Simcenter 3D is an integrated environment in which you perform all of your CAE pre- and post-processing. Unrivaled geometry manipulation tools help you intuitively defeature and abstract computer-aided design (CAD) geometry from any source. Comprehensive meshing and modeling tools support multiple simulation applications and give you the unique capability to associate your analysis model to design data. This helps you speed the tedious modeling process and keep analysis models in sync with the latest design.

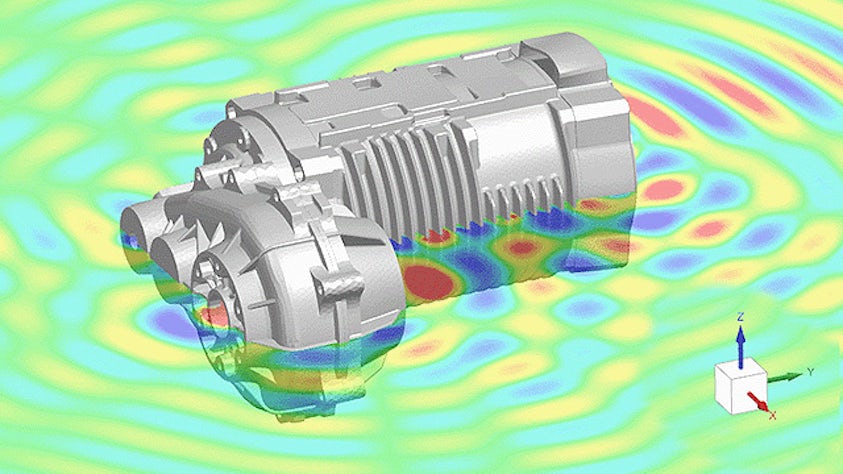

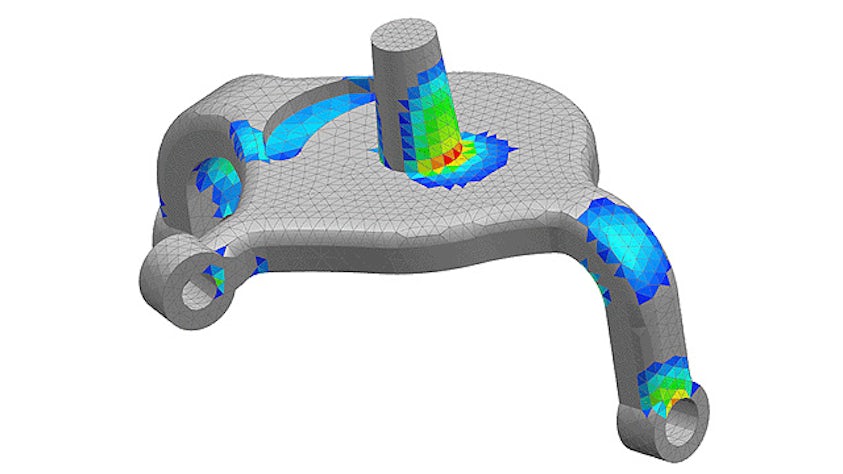

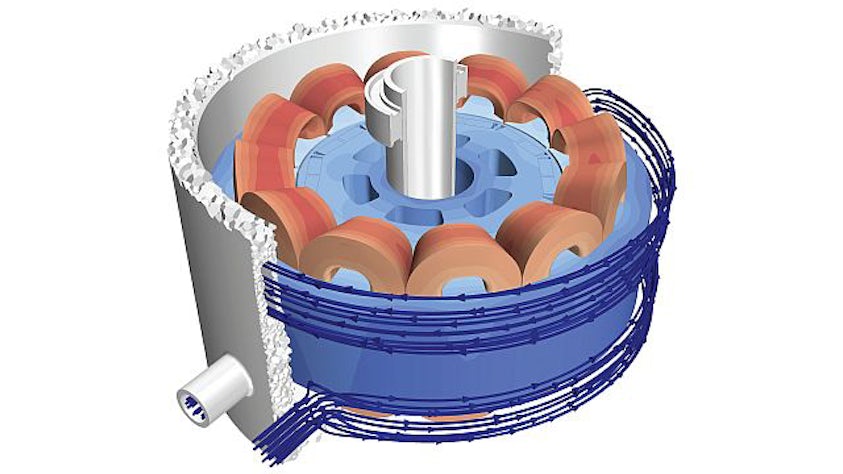

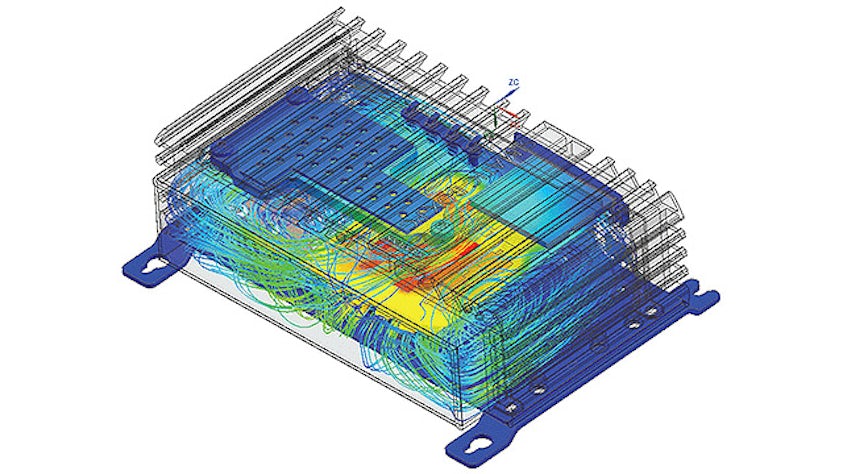

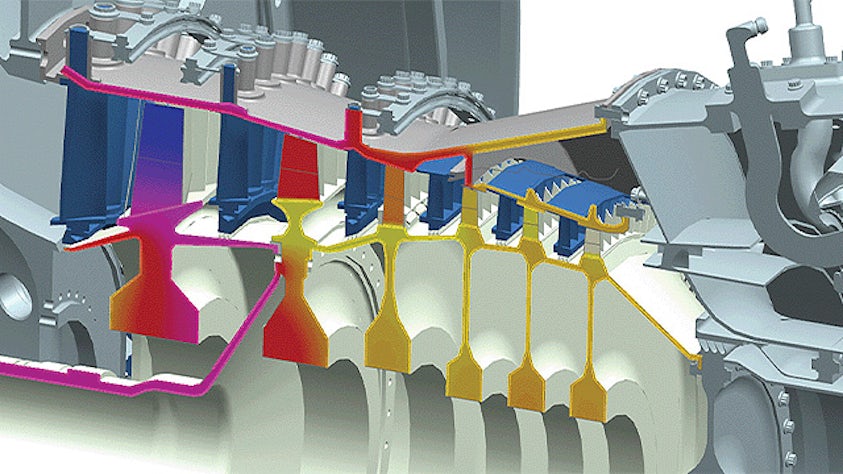

Model the complexity – by simulating many physics phenomena

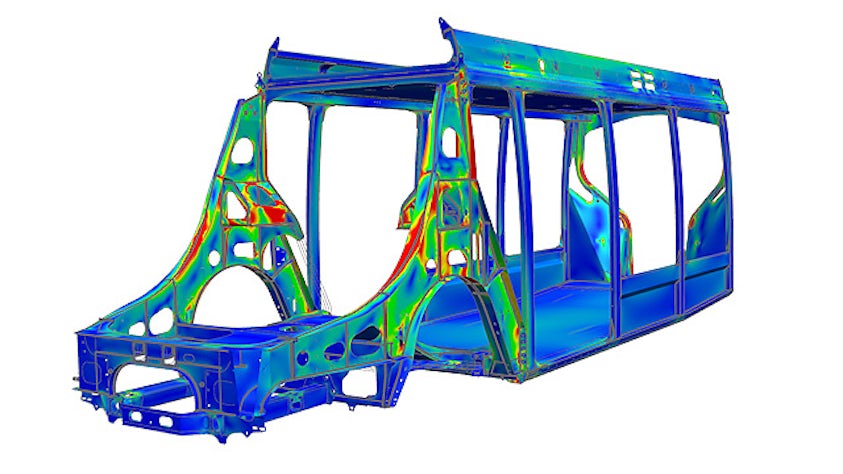

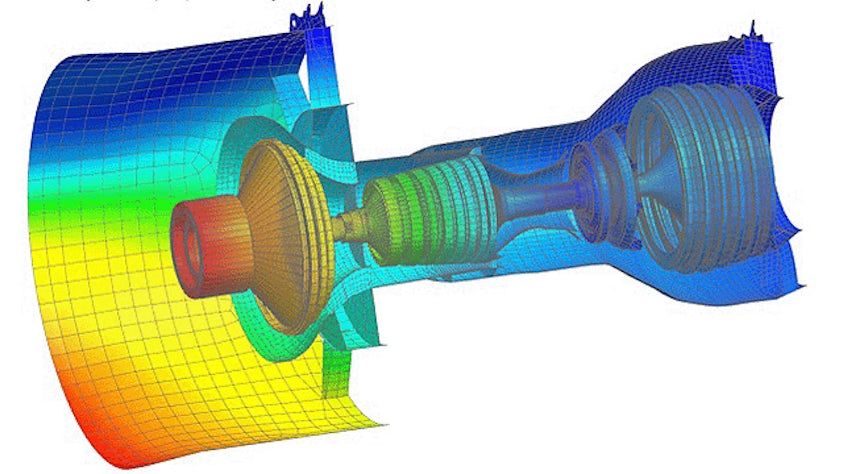

Simcenter 3D integrates industry-standard, multidiscipline simulation solvers, all from the centralized engineering environment. The Simcenter 3D simulation solvers for structures, acoustics, structural dynamics, durability, motion, thermal, electromagnetics and more help you to predict real-world performance for a large variety of physics domains. This tight integration of solutions streamlines multiphysics processes that would otherwise be too challenging to perform.

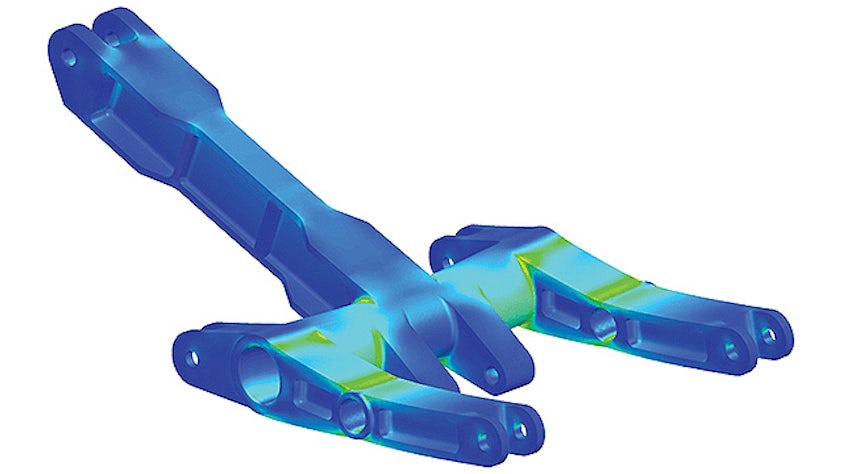

Explore the possibilities – through simulation automation

The true value of simulation is not just in reducing the number of physical tests you need, but also in the number of design options that simulation lets you explore. Simcenter 3D lets you automate modification of geometry, simulation models and solution parameters so that you can explore with integrated design space exploration tools. You can also use Simcenter 3D as a pre- and post-processing tool for other common, third-party solvers like ANSYS, Abaqus, MSC Nastran and LS-Dyna. This means you can take advantage of the excellent CAD associativity, geometry editing, and comprehensive meshing tools to explore all of your simulation needs.

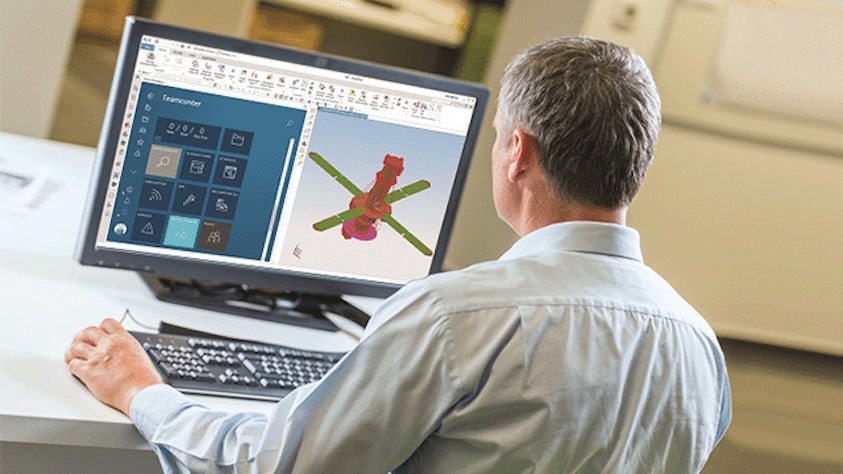

Stay integrated – through seamless data management

As part of the Simcenter portfolio of simulation tools, Simcenter 3D integrates with the digital thread that spans 3D simulation, 1D simulation and testing solutions. However, simulation is just a part of a longer digital thread running through your product development processes. Simcenter 3D also keeps your simulation processes tied to this longer thread with a seamlessly managed environment that connects with simulation data management. This keeps your simulation processes in sync with digital development processes like CAD, routing, product requirements and manufacturing processes.

Enjoy flexible licensing

To make Simcenter 3D even more flexible for your simulation team, Simcenter 3D offers value-based token licensing. Instead of purchasing individual licenses for each add-on module, you can buy packs of tokens that allow you and your team to instantly access most Simcenter 3D modules.

See what’s new in Simcenter 3D 2506

From advanced modeling techniques for aerostructures to integrated workflows that optimize electric vehicle performance, the new features in Simcenter 3D are set to revolutionize the way you work. Dive in and discover how these pioneering updates can drive efficiency, accuracy, and innovation in your projects!

- Margin of safety – Advanced load idealization

- Integrated e-drive workflow - improvements for NVH and bearing visualization

- Turbomachinery - Multi-stage cyclic symmetry

- Process improvements - for pass-by noise, additive manufacturing and general pre/post