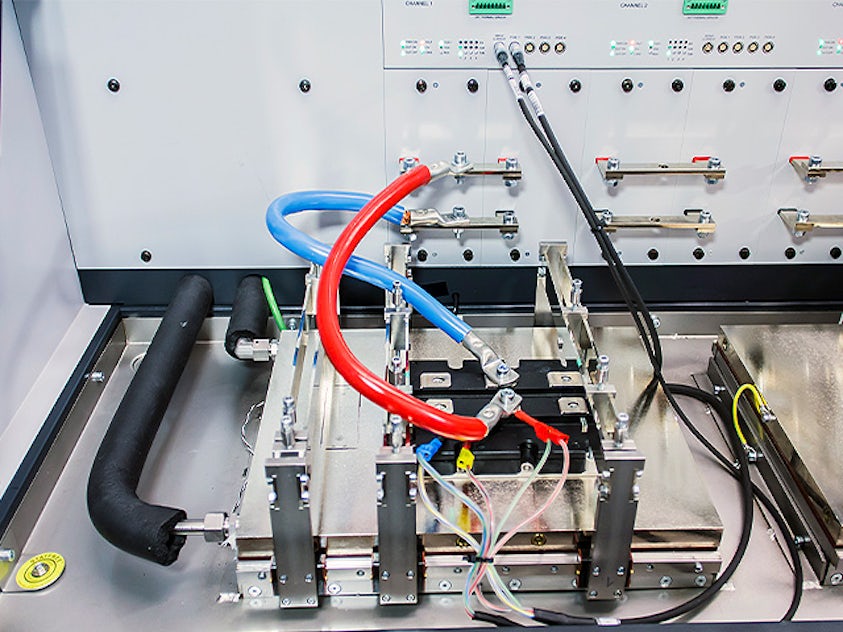

Simcenter Micred Power Tester combines active power cycling with transient thermal characterization and thermal structure investigation. Perform the non-destructive structure-function assessment while the device is mounted, providing a full electrical and structural assessment of the device.

Rely on a reliable tool

The Simcenter Micred Power Tester supports automatic testing and diagnosis of possible failure causes of power components on the manufacturing floor. The energy demands of both consumer and industrial electronic systems are increasing, and power electronics component suppliers as well as OEMs are faced with the challenge of providing the highly reliable systems needed for aviation, electric vehicles, trains, power generation, and reusable energy production. The Simcenter Micred Power Tester can power the modules through tens of thousands, potentially millions, of cycles while simultaneously providing a real-time failure-in-progress diagnosis.

Receive real-time failure diagnosis

The Simcenter Micred Power Tester is the only machine built for manufacturing as well as laboratory environments that does automated power cycling while producing analytical data for real-time failure-in-progress diagnosis. It’s designed to perform lifetime testing to test the reliability of applications that use power electronic modules.

Accelerate the process

The Simcenter Micred Power Tester is unique since it provides fully automated power testing and cycling at the same time, on the same machine, without having to remove the device under test during the process. A simple touch-screen interface allows a technician to use it on the manufacturing floor and/or failure analysis engineer to use it in the lab.

Characterize automotive IGBTS – a unique non-destructive power cycling test method

This paper discusses the unique, non-destructive power cycling test method to characterize these critical components: understanding heat path, reducing the risk of failure and improving reliability under high loads.