Certification and qualification of products require specific dynamic tests whereby external excitation – shock, vibration and noise – is applied. In these tests, excitation systems reproduce the realistic environmental conditions that products are subject to, such as shocks during transportation, vibrations during operation, or extreme launch conditions.

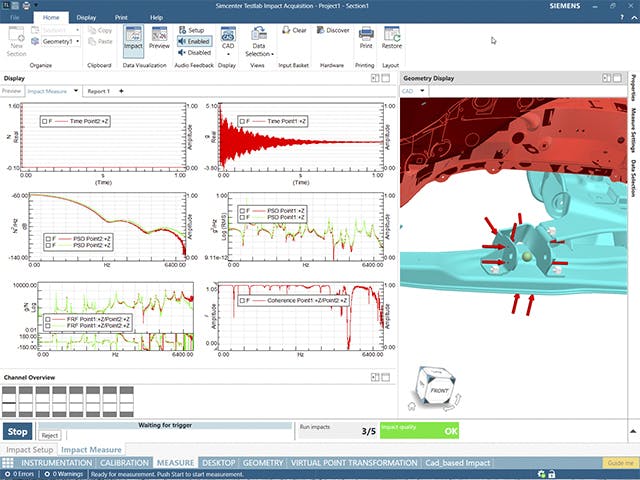

Our end-to-end solution for shock and vibration testing integrates an effective, high-speed multi-channel closed-loop shaker control system with parallel data acquisition and powerful analysis capabilities. It is a very intuitive tool for routine random, shock, sine, and combined modes testing. It features comprehensive time data replication applications, advanced functionalities for multi-axis vibration testing and acoustic field control, and is perfectly safe for vibration and acoustic qualification of space systems. Functionalities for test definition and analysis complement the offering.

Acoustic qualification testing for space hardware

Noise levels generated at launch can reach 146 decibels (dB) or higher which can cause structural damage and ultimately jeopardize functionality of the payload. Learn how Simcenter can help you engineer mission success with dynamic environmental testing of space hardware.