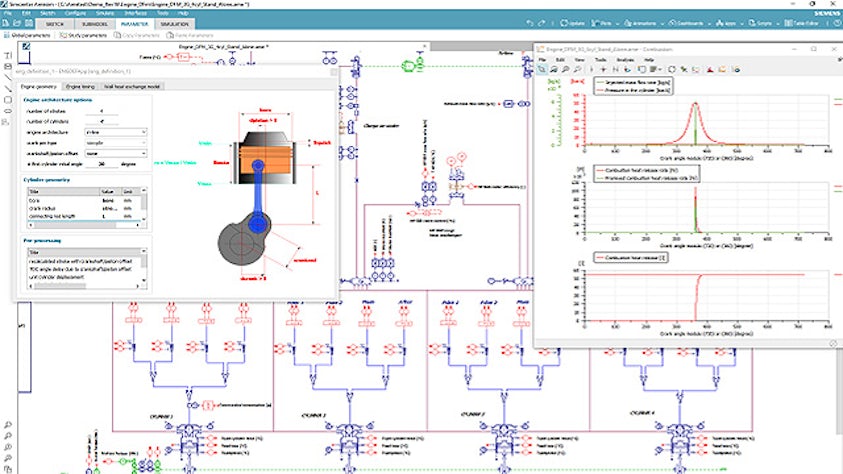

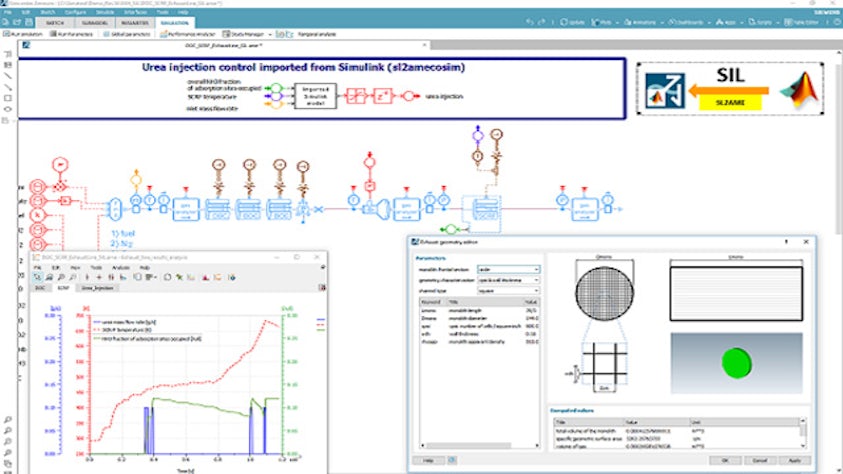

Evaluate, design and optimize complete internal combustion engine systems, from air management and combustion to exhaust after-treatment and engine controls, by using accurate physical engine and component models. The capabilities for internal combustion engine simulation are developed in close collaboration with IFP Energies nouvelles.

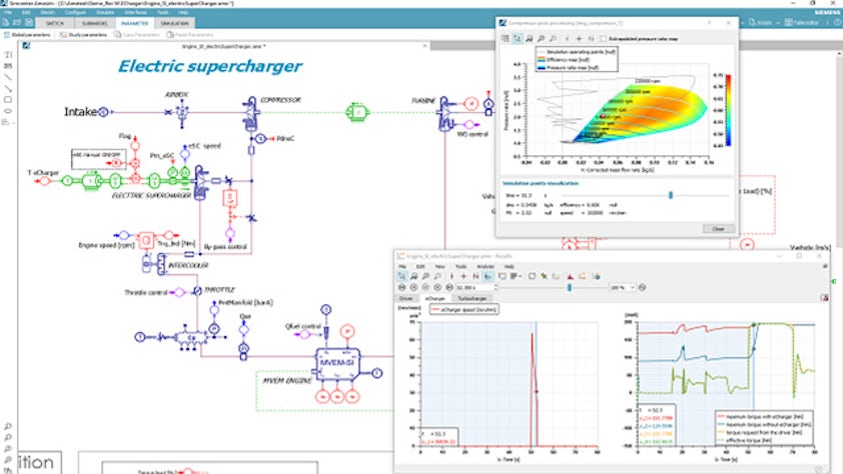

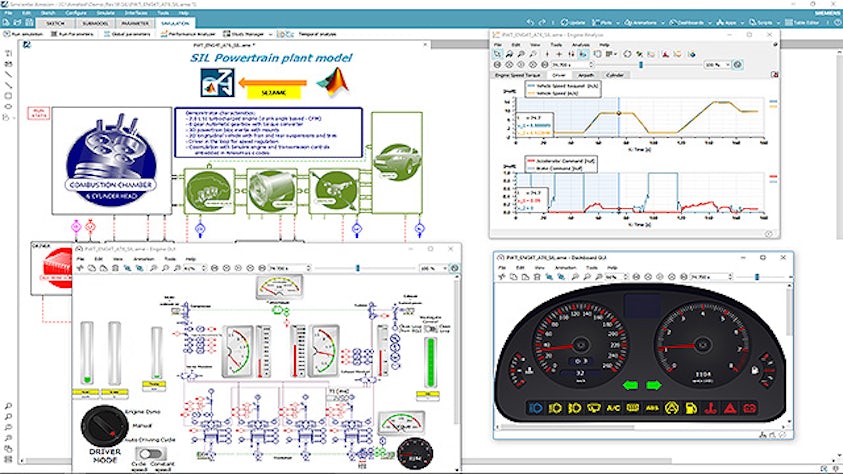

By applying a system simulation approach using Simcenter, you can now study integration with fuel injection subsystems, engine thermal management, electrical devices, powertrain and various other components, as well as adapt model definitions to a wide range of scenarios. Simcenter allows you to analyze the impact of advanced technology choices and gives you a powerful toolset to investigate alternative engine architectures and concepts.

Is your powertrain roadmap digital enough?

Next Euro 7 and Tier 4: Addressing the challenges that lay ahead. Balancing/Optimizing conventional powertrain design into an electrified powertrain.