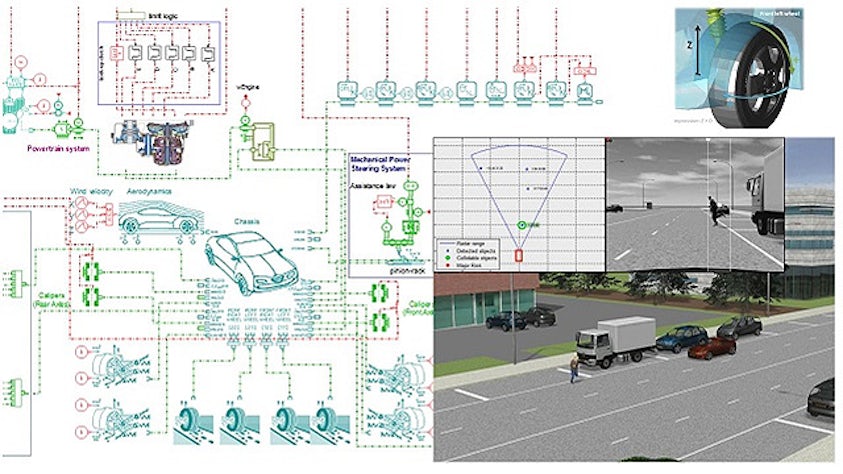

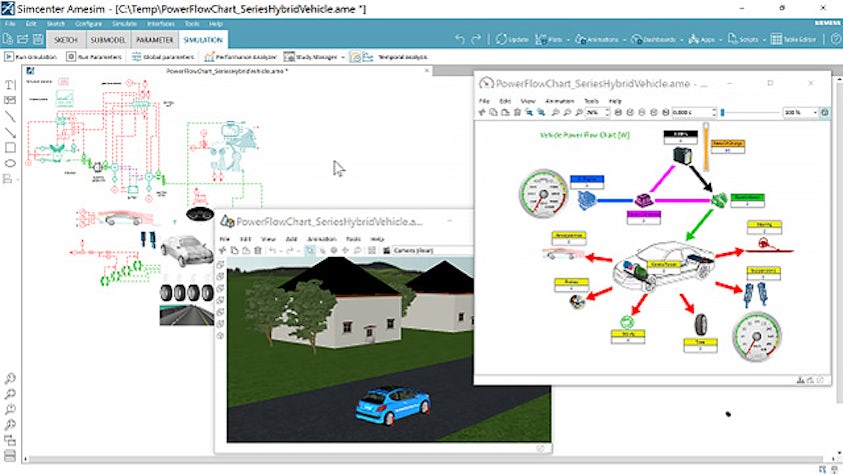

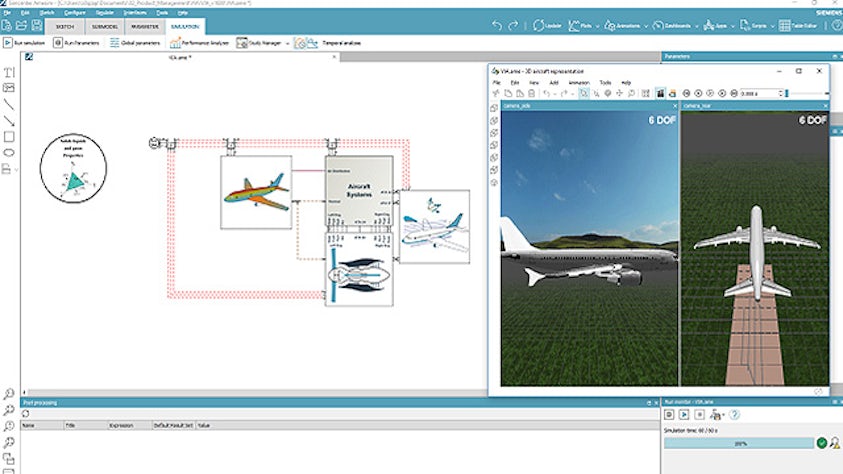

Extend the breadth of simulation capabilities to increase model fidelity and engineering efficiency. Integrating different simulation tools throughout the lifecycle of your system, from early design to the operation phase, allows you to address the digital continuity challenge and to increase the efficiency of your workflows and the collaboration between different departments.

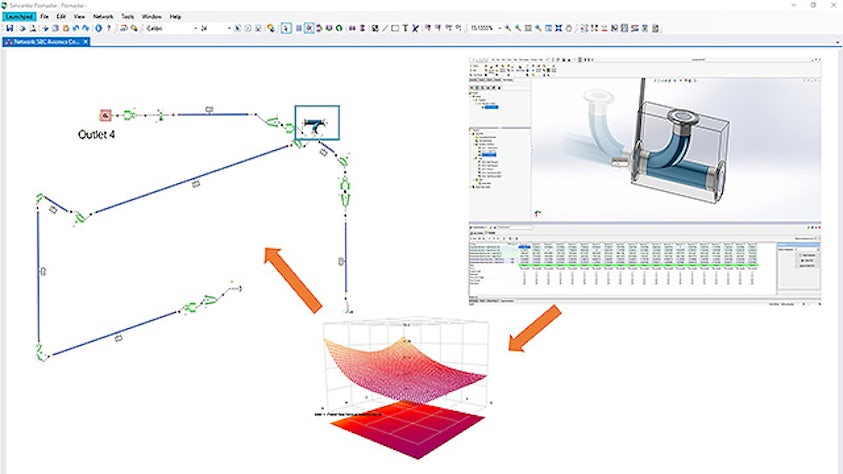

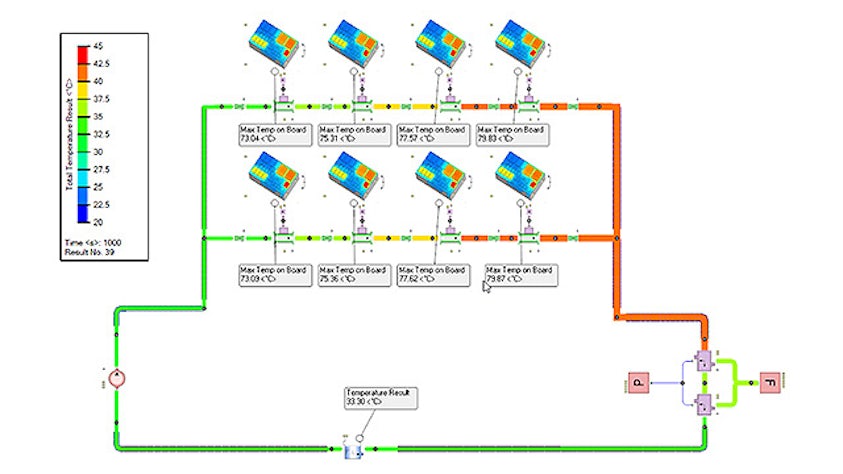

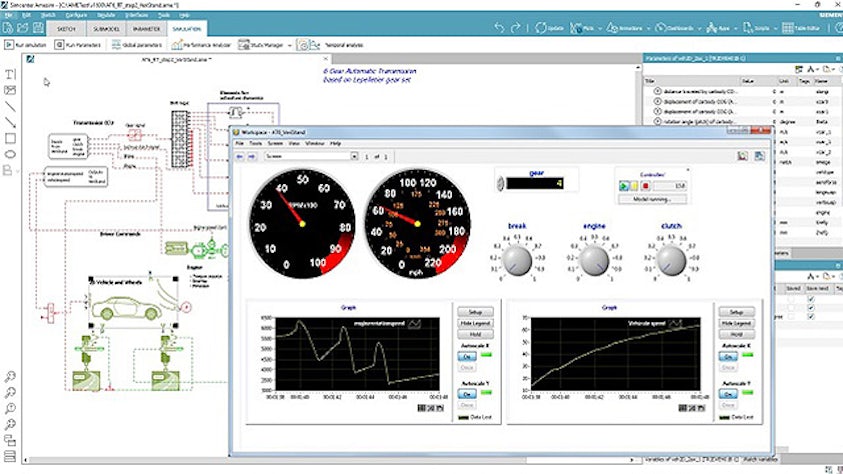

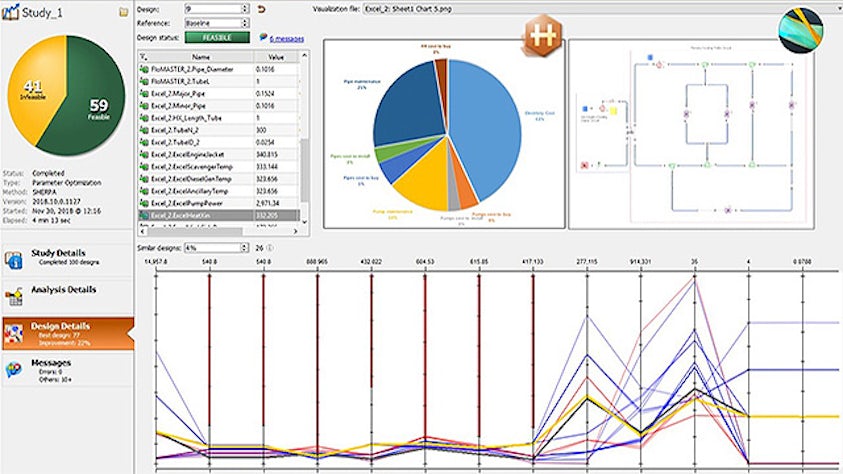

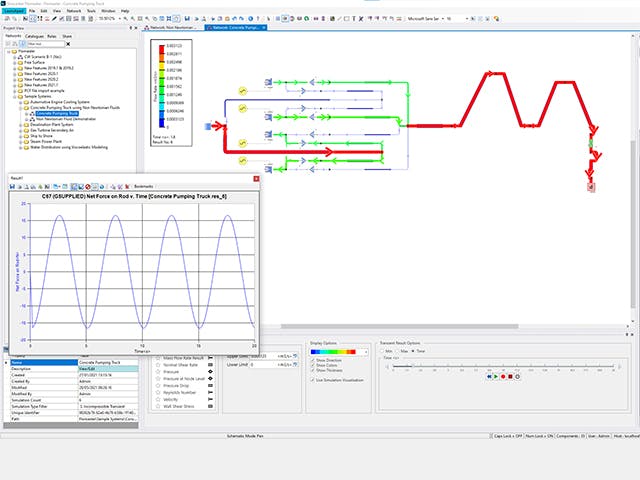

Connecting to a product lifecycle management (PLM) system allows you to make sure that all of the data is consistent because they come from a single source of truth. Geometrical data is used to automatically create system models. Bespoke connectivity to 3D computational fluid dynamics (CFD) allows you to increase the model fidelity by characterizing non-standard components based on 3D CFD results or by creating seamless co-simulations between 1D and 3D. The support of open standards allows you to run system-of-system simulation to analyze the interactions between different systems. Finally, design space exploration allows you to discover innovative design faster.

From heavy equipment component design to system integration

Why heavy equipment manufacturers are using Simcenter.