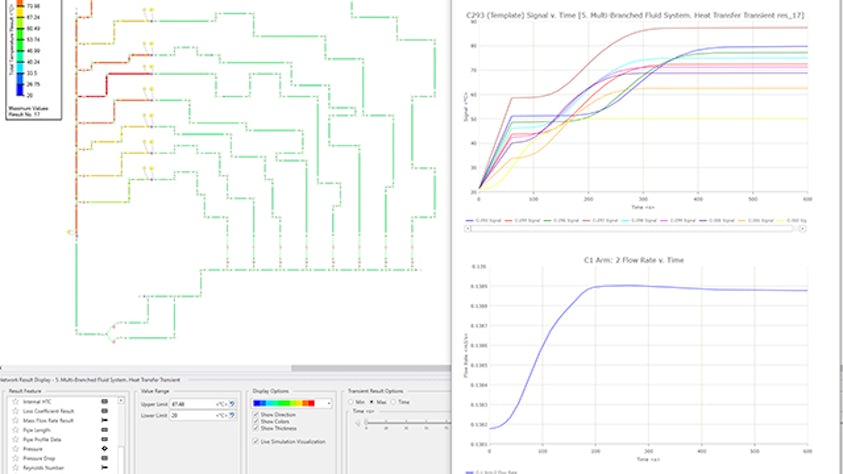

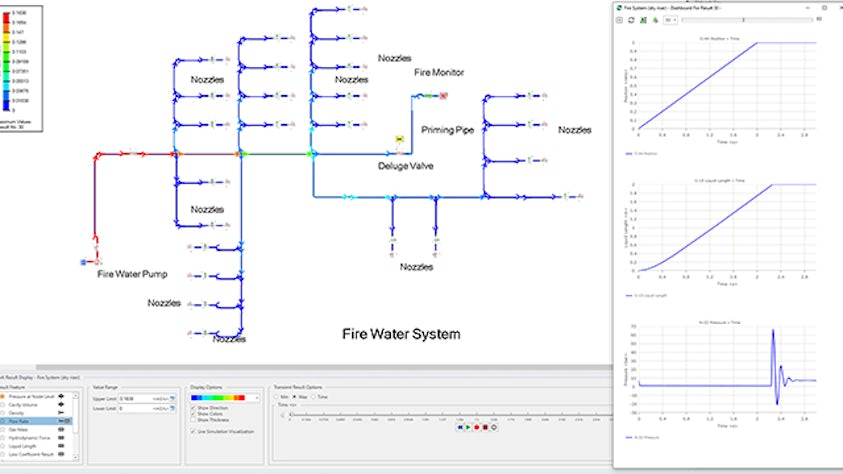

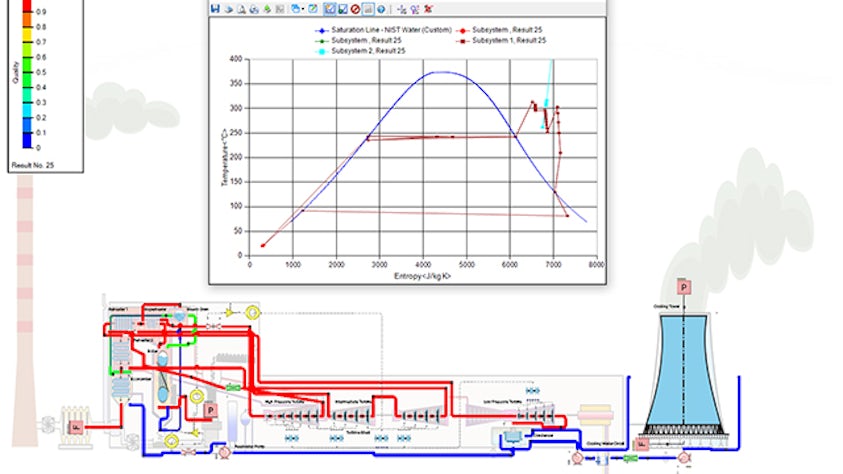

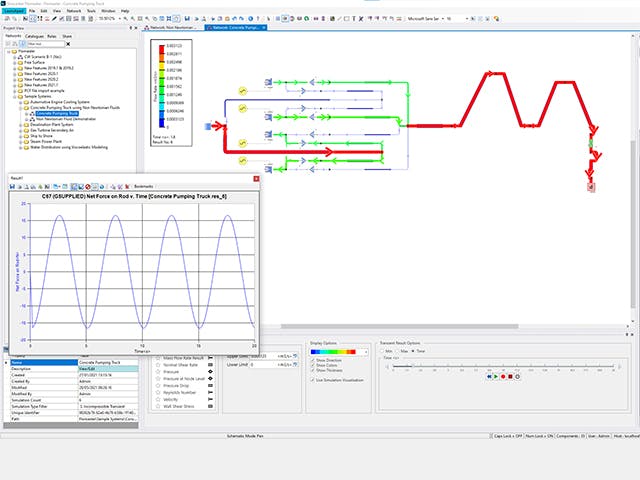

Simcenter enables you to optimize the efficiency of your thermo-fluid systems and ensure they always operate safely. Fluid systems play key roles in all industries. They are used for many disparate tasks ranging from cooling and heating to transport of different products, from energy production to ensuring safety of the entire plant. Optimizing their performance and making sure they can operate safely at all times is paramount.

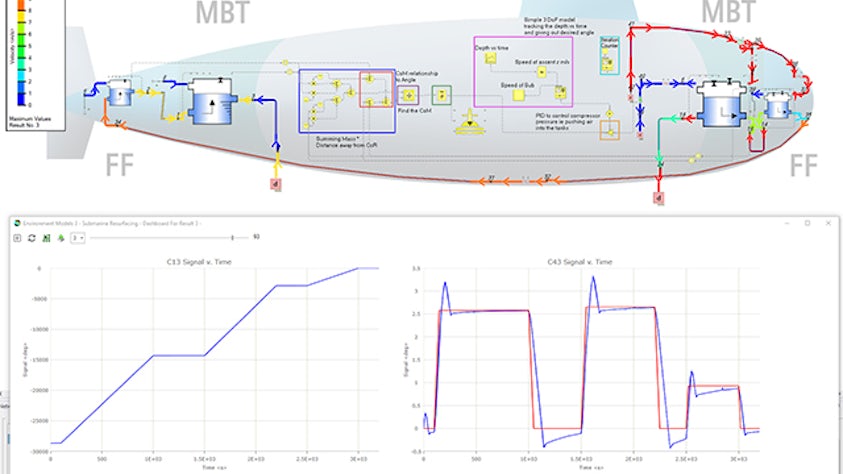

Fluid system simulation allows you to size and balance your thermo-fluid system early in the design phase. It also allows you to model different operating conditions of your system to make sure it can always operate at maximum efficiency. The analysis of emergency and failure scenarios is critical to guarantee the safety of the system under any circumstances. You can then re-use the digital twin of the thermo-fluid system during the operation phase for real-time monitoring to maximize efficiency and safety.

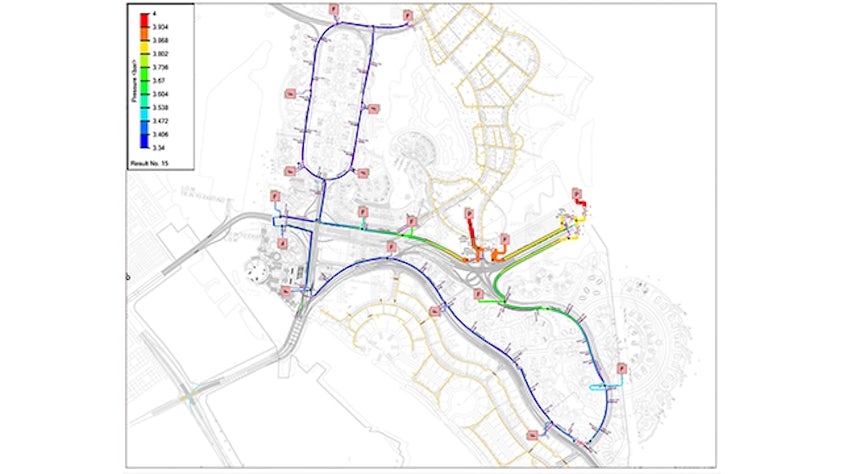

Using Simcenter Flomaster to understand a hydro-pumped storage scheme

Learn how engineers at JS Pump and Fluid System Consultants used Simcenter Flomaster to gain an early understanding of critical hydraulic design parameters for the Burdekin Hydro Pumped Storage Scheme in Australia.