Wykorzystanie dostępu do danych na żywo

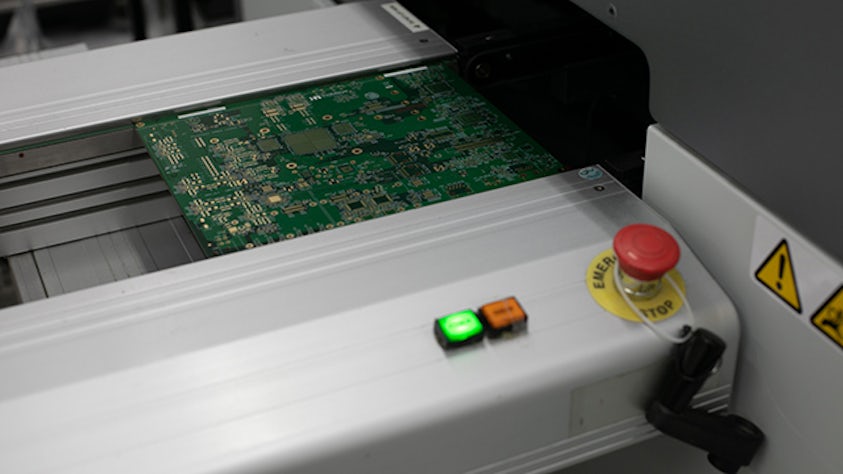

Zmaksymalizuj wydajność przepływu danych dzięki automatycznej normalizacji wszystkich danych na hali produkcyjnej. Opcenter Connect Electronics gromadzi dane na żywo z każdego procesu lub maszyny na hali produkcyjnej, łącząc i normalizując ujednolicone, modułowe pozyskiwanie danych z oprogramowania. Umożliwia pełny przepływ danych między halą produkcyjną a aplikacjami wewnętrznymi, skracając czas i zmniejszając nakład pracy.