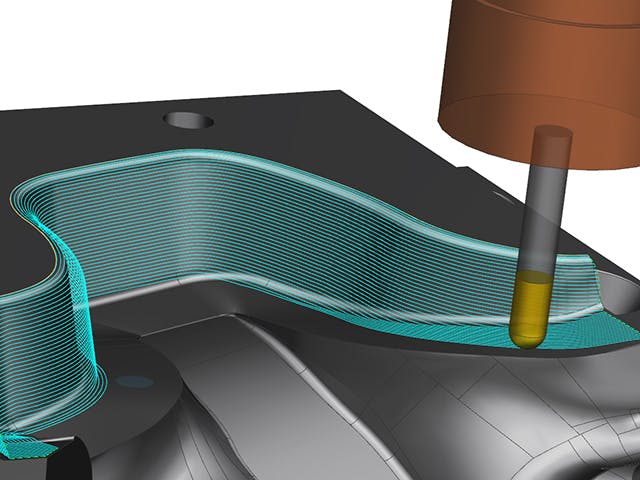

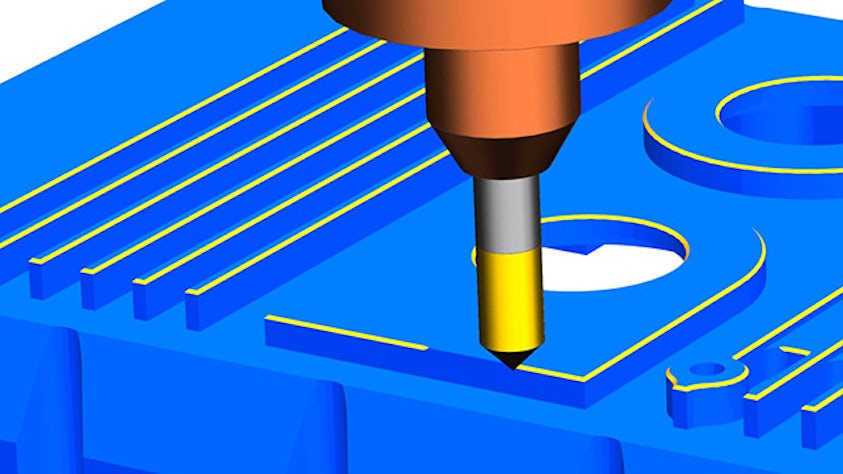

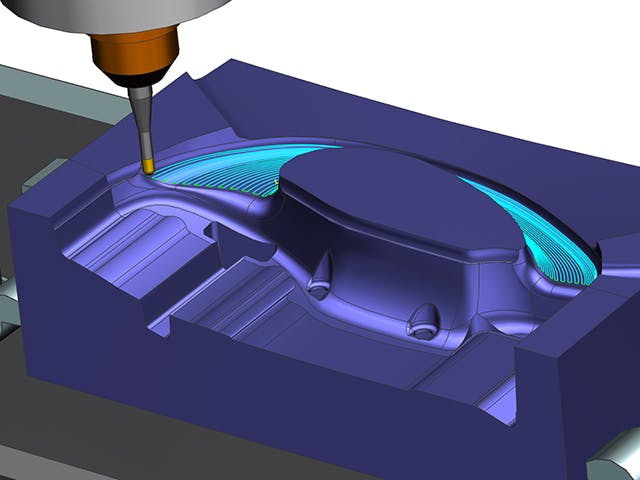

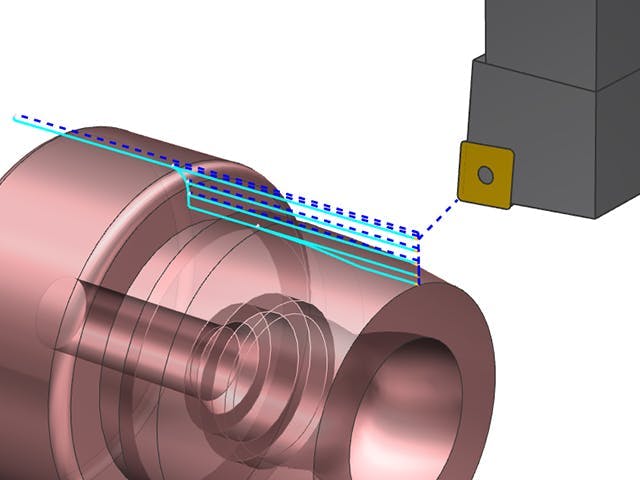

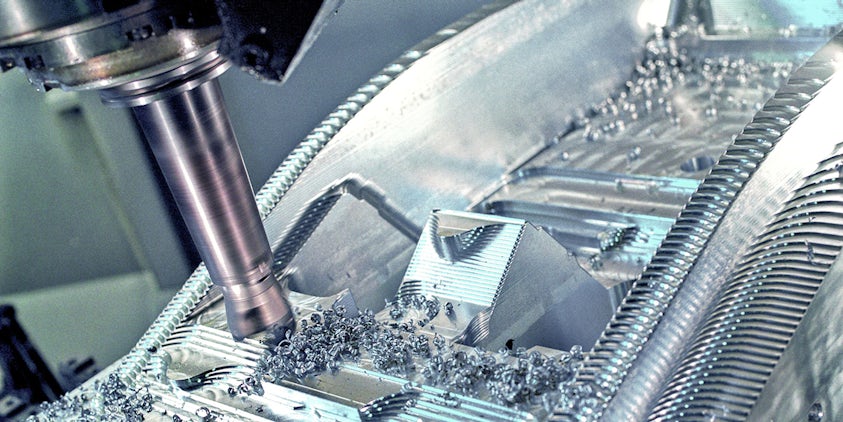

Simplify the programming of the most demanding freeform parts created in any CAD system using advanced capabilities for 3-axis milling.

Accelerate machining and improve quality

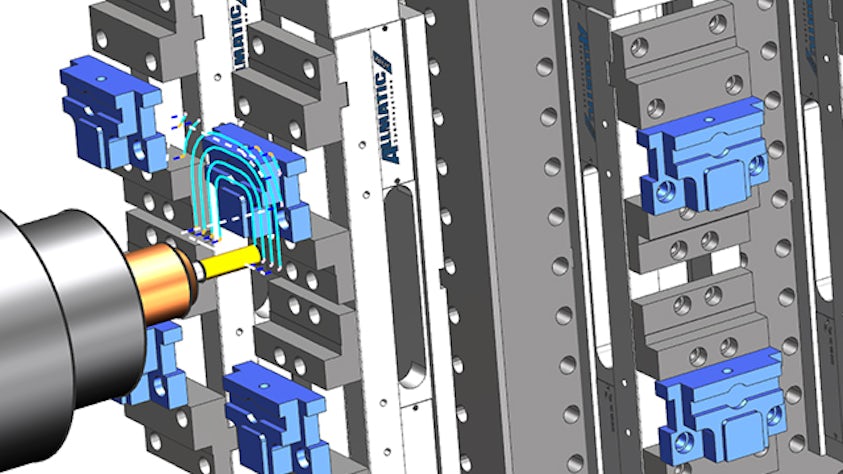

Create smooth and highly efficient toolpaths with minimum input, such as the advanced finishing operations that follow the part natural shape, achieving mirror-like surface finishes.

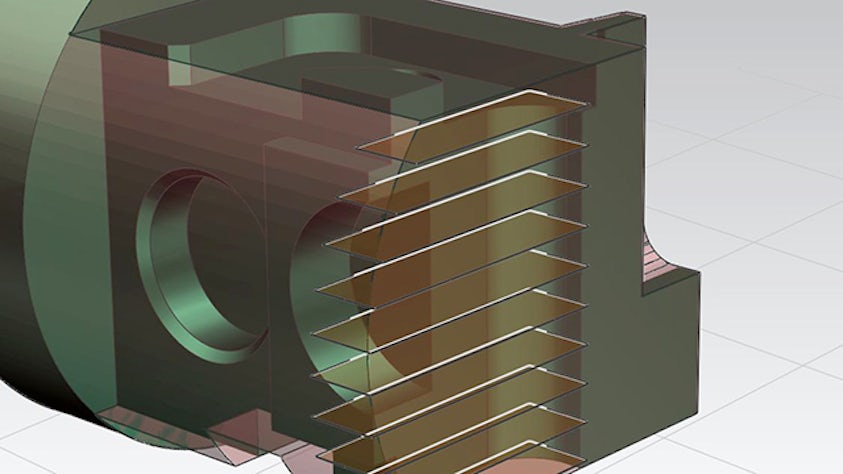

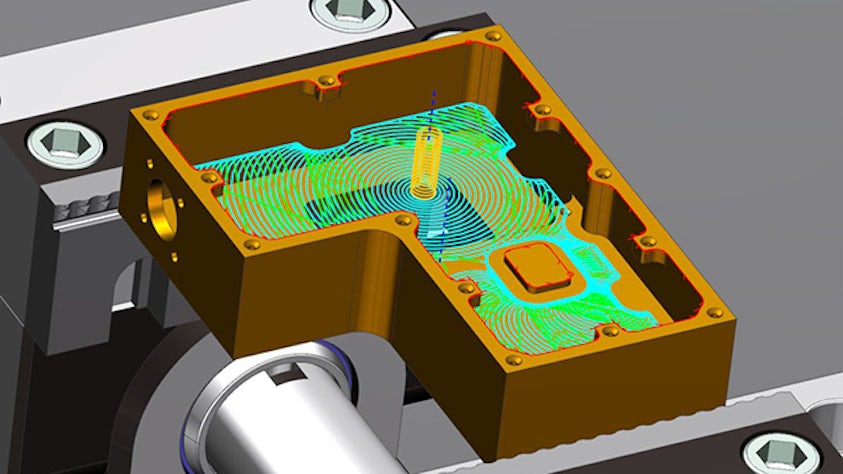

Reduce machining cycles by up to 60% and deliver higher quality parts, such as mold and dies, using the innovative 3D Adaptive Roughing with its deep cuts at high speeds.

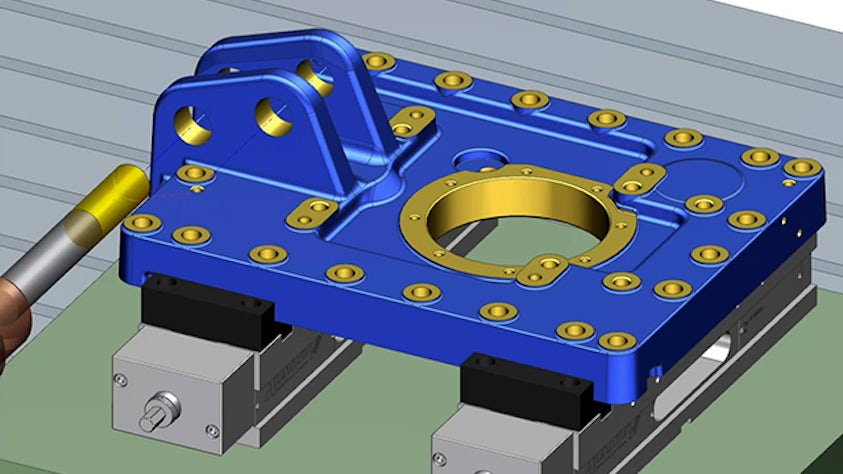

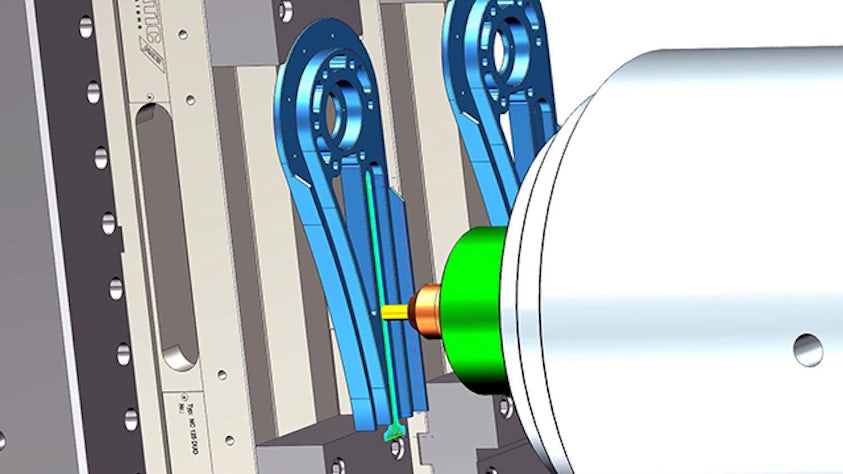

Use integrated CAD tools

Directly edit 3D part models using synchronous technology for faster NC programming. Additionally, develop cast and stage models using interactive editing tools.

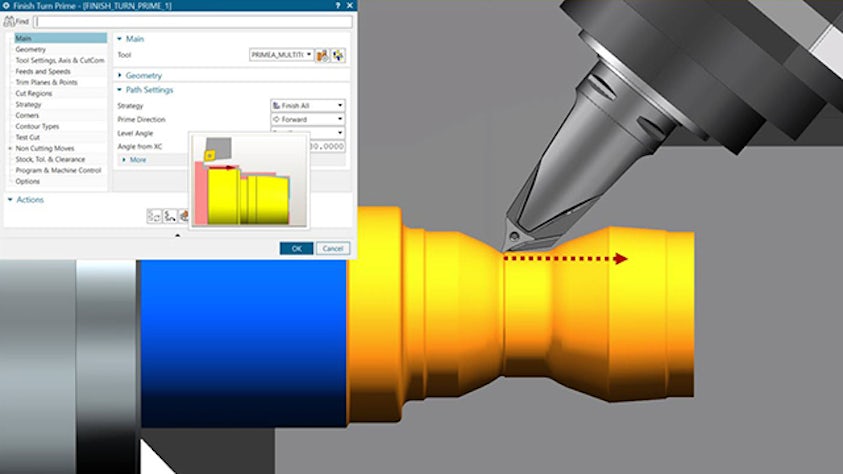

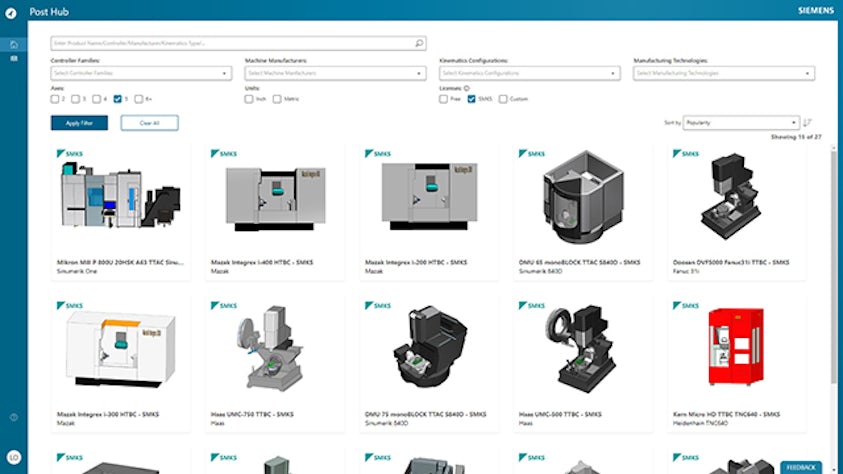

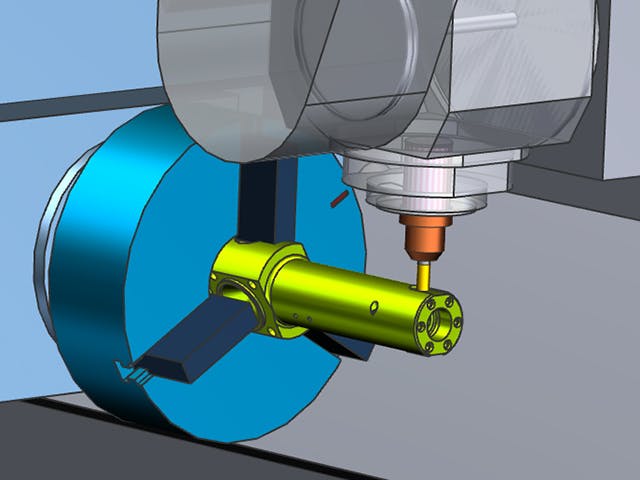

Output validated programs

Use integrated cloud-based postprocessing and machining simulation to output validated, machine-specific NC programs. Transfer the manufacturing data to the shop floor using associative and complete shop documentation, including tool lists, setup sheets and 3D drawings.

NX CAM provides advanced programming capabilities for 3-axis milling, including:

- 3D Adaptive Roughing

- Rest milling

- Guide curve finishing

- Z-level finishing

- Cut region control

- Spiral and helical finishing

- In-Process Workpiece (IPW)

- Toolpath verification

- Postprocessing

- Shop floor documentation

*The 2.5-axis milling capabilities are included too

Included integrated CAD tools:

- Synchronous technology

- Assemblies

- CAD translators