Create order-based multi-constraint scheduling

Create order-based schedules. Rank or weigh items to prioritize orders. Sequencing algorithms take into account resource availability and additional constraints the order requires. Schedules can account for different operation run speeds on resources. Apply sequence dependent changeover times based on an operation’s attributes and allow overlaps and slack time between operations.

Model and optimize resource constraints

Model advanced resource constraints, such as rules about concurrent rule usage. Advanced inter-operation constraints include limits on the time between operations and how much operation times can be extended. With advanced schedule optimization, you can define additional schedule optimization rules to deal with problems such as minimizing changeover times, preferred sequencing and campaigning.

Model material usage

Implement custom rules about how materials are consumed to ensure that sub-assemblies and raw materials are used according to business rules. When allocating materials, the system filters and ranks data to allow quality-related or customer-specific material usage constraints to be included.

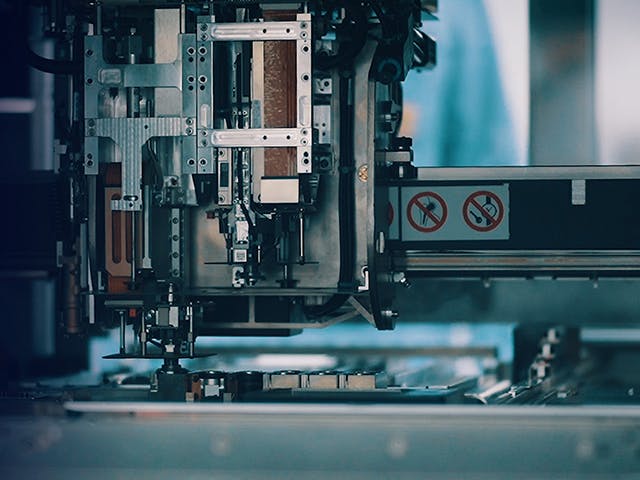

Visualize assembly processes

Visualize the assembly process from raw materials through to finished goods and sales orders. The material explorer in Opcenter Scheduling shows a graphical view of the material dependencies as well as plots of stock levels over time. See where shortages will occur and choose to keep them as a constraint or ignore them.

View schedules and track order progression

Sales offices use viewers to track the progress of orders. Carry out order inquiries against a read-only copy of the published schedule. Management can compare actual times with scheduled completion times to assess performance of the production process. On a shop floor, cell supervisors or machine operators can use the viewer to see up-to-the-minute work to-do lists.